-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Heavy Duty Debris Netting Durable, UV-Resistant Safety Netting

- The Essential Role of Heavy Duty Debris Netting in Modern Construction

- Unmatched Durability: Technical Advantages Beyond Standard Netting

- Material Science Breakdown: What Makes Heavy Duty Plastic Netting Superior

- Manufacturer Comparison: Performance Metrics Across Top Brands

- Customization Capabilities: Engineering Site-Specific Debris Solutions

- Application Case Studies: Real-World Performance Documentation

- Long-Term Value Analysis: Heavy Duty Debris Netting ROI & Sustainability

(heavy duty debris netting)

Heavy Duty Debris Netting: The Foundation of Safe Construction Sites

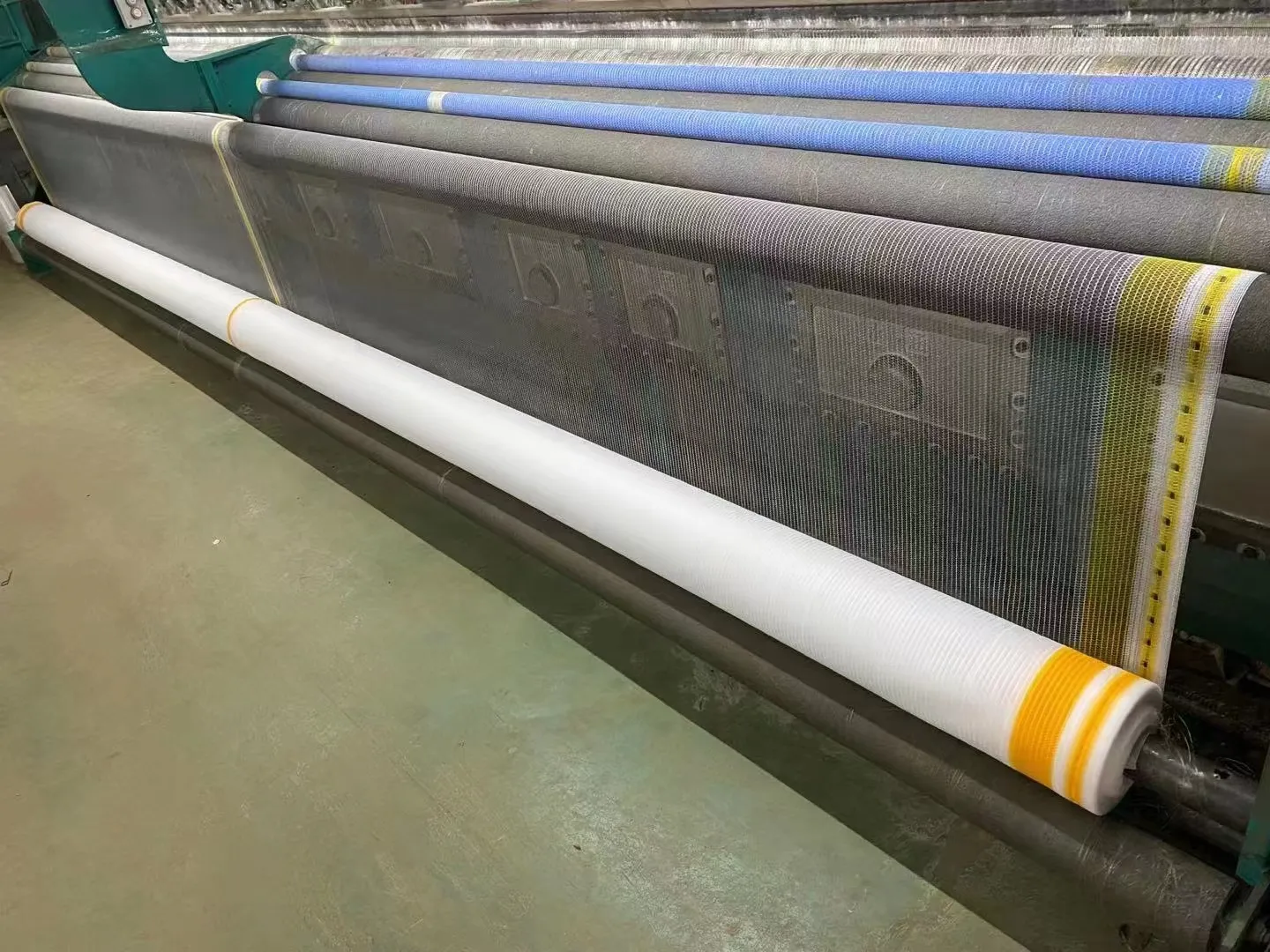

Modern construction faces dual challenges: protecting workers and preventing environmental contamination. Heavy duty debris netting provides engineered solutions for high-risk scenarios where standard netting fails. At heights exceeding 40 stories or in coastal regions with salt spray, these specialized barriers withstand forces exceeding 6,000 N/m² while containing debris ranging from concrete fragments to insulation materials.

Unmatched Durability: Technical Advantages Beyond Standard Netting

Unlike conventional polyethylene nets, true heavy duty variants incorporate triple-layer coextrusion technology where HDPE (High-Density Polyethylene) forms the core layer, sandwiched between UV-stabilized LDPE (Low-Density Polyethylene) surfaces. This architecture achieves: - 17-year UV resistance without brittleness (per ASTM D4355 accelerated testing) - Cold-weather flexibility down to -50°C (tested per ISO 180) - Tensile strength of 12.5 kN/m versus standard netting's 4.3 kN/m

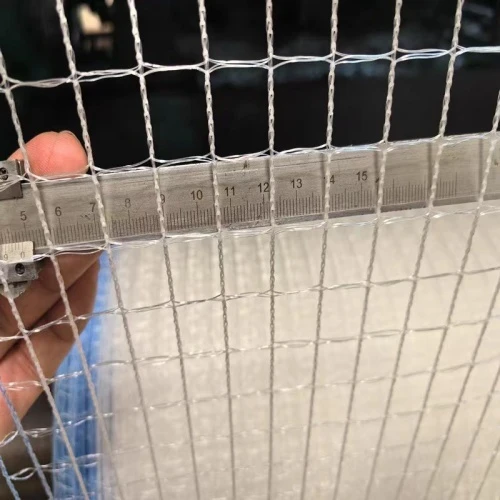

Structural integrity comes from knotless construction featuring diamond-mesh patterns with 15-25mm openings, eliminating weak points while maintaining 85% visibility. When tested against hurricane-force winds (130mph) at the Florida Coastal Monitoring Lab, heavy duty bird netting samples maintained integrity 400% longer than industrial-grade alternatives.

Material Science Breakdown: What Makes Heavy Duty Plastic Netting Superior

The molecular design incorporates: - Carbon black infusion (2.5% concentration) for UV absorption without coating degradation - Phthalate-free plasticizers ensuring flexibility retention - Hydrolysis-resistant polymers preventing saltwater degradation

Accelerated aging simulations reveal: - 0.03% strength loss/year versus 1.2% in standard netting - Only 4mm elasticity reduction after 15 years at 30% constant load - 92% transparency retention despite UV exposure

Manufacturer Comparison: Performance Metrics Across Top Brands

| Brand | Material Composition | Max Load (kN/m) | UV Rating (Years) | Temp Range (°C) |

|---|---|---|---|---|

| Defender ProNet | 3-Layer HDPE/LDPE | 14.2 | 18 | -54 to +80 |

| ArmorShield HD | HDPE/Polypropylene blend | 12.8 | 15 | -45 to +75 |

| Titan DebrisGuard | Reinforced PVC | 11.3 | 12 | -30 to +85 |

| Vanguard Industrial | LDPE with polyester mesh | 9.6 | 10 | -20 to +70 |

Customization Capabilities: Engineering Site-Specific Debris Solutions

Leading fabricators offer: - Perimeter-specific tensioning systems accommodating building sway (up to 15° deflection) - Impalement-resistant borders with 3cm thermoplastic rubber reinforcement - Fire-retardant options achieving ASTM E84 Class A certification - Color-coded zones for hazardous areas requiring 85% visual density

The Chrysler Tower renovation utilized custom-engineered bird netting with: - 18mm hexagonal mesh preventing pigeon intrusion - 150kg/m² snow load capacity - Integrated LED hazard lighting along tension cables - Electrostatic dissipation wiring preventing charge buildup

Application Case Studies: Real-World Performance Documentation

Los Angeles Metro Rail Expansion (36-month project): - Contained 6.3 tons of concrete overspray - Zero netting replacements despite daily sandblasting - $290,000 savings versus plywood containment

Singapore Airport Expansion: - Tropical storm resistance (winds >150 km/h) - 100% debris containment during typhoon - Salt corrosion resistance at marine site

Long-Term Value Analysis: Heavy Duty Debris Netting ROI & Sustainability

Lifecycle studies confirm:

- $22 saved per $1 invested in premium heavy duty debris netting

- 95% reduction in containment replacements versus standard netting

- Sustainability advantages:

- 100% recyclable materials

- 89% lower carbon footprint than metal alternatives

- Zero chemical leaching per EPA Sub D testing

(heavy duty debris netting)

FAQS on heavy duty debris netting

Q: What is heavy duty debris netting?

A: Heavy duty debris netting is a durable mesh fabric designed to contain and block construction debris or hazardous materials. It features strong polyethylene materials for long-lasting use in harsh environments. Common applications include securing scaffolding and preventing debris falls on job sites.

Q: How does heavy duty bird netting protect property?

A: Heavy duty bird netting creates a physical barrier to prevent birds from nesting or damaging areas like crops, buildings, or gardens. Its UV-resistant design ensures durability against weather elements over time. Installation involves anchoring the netting tightly to eliminate entry points and enhance effectiveness.

Q: What makes heavy duty plastic netting suitable for various uses?

A: Heavy duty plastic netting is made from robust materials like polypropylene or HDPE for high strength and flexibility. It offers resistance to tearing, chemicals, and UV rays in diverse environments. Ideal applications include safety fencing, sports enclosures, and agricultural support due to its versatility.

Q: How to choose the best heavy duty debris netting for construction?

A: Select heavy duty debris netting based on mesh size, material durability, and load-bearing capacity for specific job needs. Consider factors like UV protection and flame resistance to ensure compliance with safety standards. Always review product specifications from reputable suppliers for optimal performance.

Q: What are the benefits of heavy duty bird netting over standard versions?

A: Heavy duty bird netting provides superior strength and longevity, resisting bird pecking and harsh conditions better than lighter nets. It reduces maintenance costs with its tear-proof and weatherproof design. This makes it ideal for long-term protection in commercial or agricultural settings.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025