-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top PVC Coated Wire Mesh Manufacturers Durable & Corrosion-Resistant

- Industry Overview & Market Data Insights

- Technical Superiority of PVC/Steel Composite Materials

- Comparative Analysis: Leading Manufacturers (2023)

- Customization Parameters for Industrial Requirements

- Installation Best Practices & Maintenance Protocols

- Cross-Industry Application Case Studies

- Sustainable Manufacturing & Future Trends

(pvc coated wire mesh manufacturers)

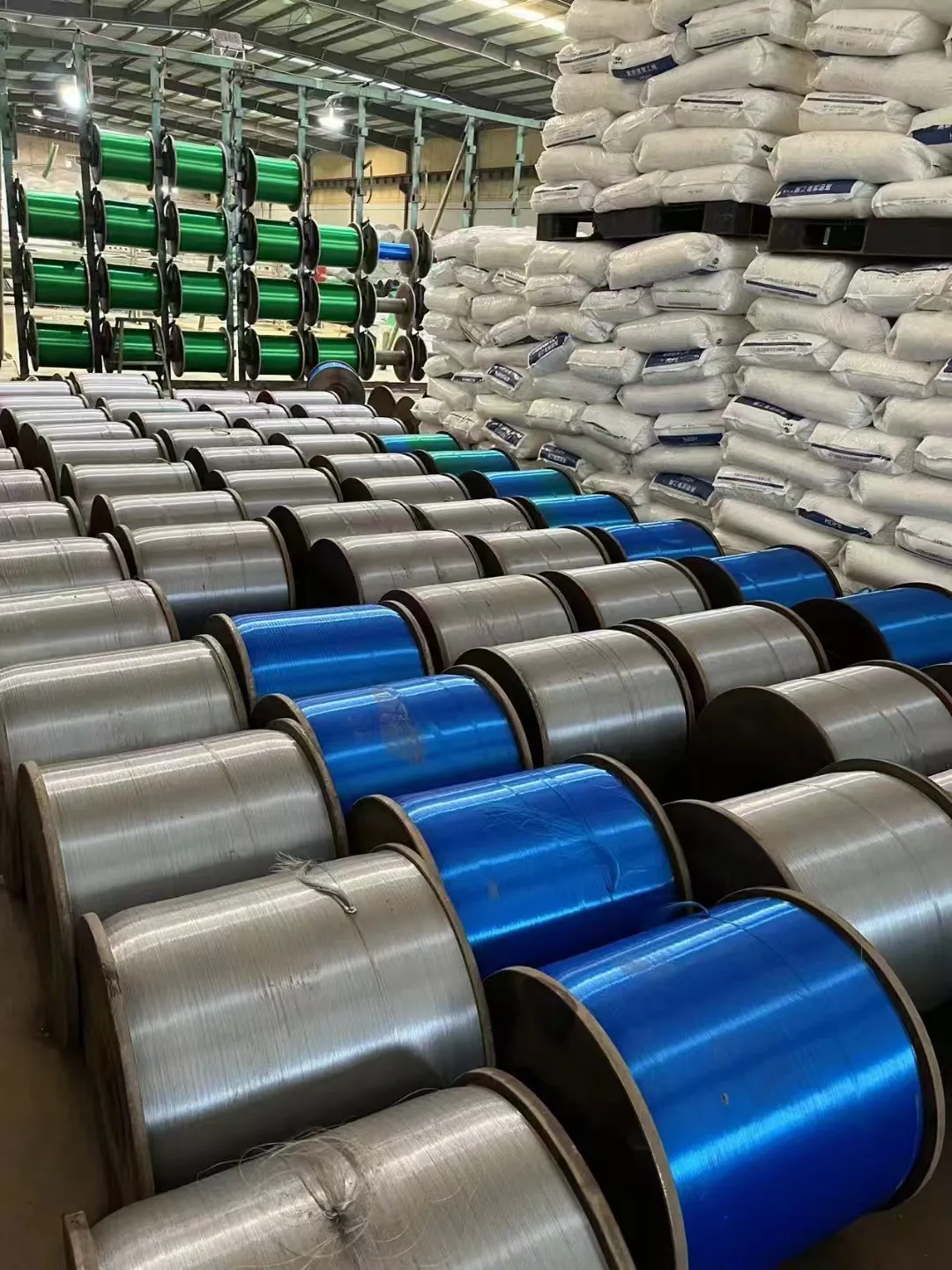

PVC Coated Wire Mesh Manufacturers Drive Infrastructure Innovation

The global PVC coated steel mesh market reached $2.8B in 2023, with 6.7% CAGR projected through 2030. Manufacturers now utilize 12-stage galvanization processes combining 220-450 g/m² zinc coatings with 0.5-1.2mm PVC layers, enhancing product lifespan to 25-40 years in coastal environments.

Advanced Material Engineering Breakthroughs

Modern powder coated steel wire employs triple-layer protection:

- Base metal: 304/316 stainless or low-carbon steel (tensile strength 350-550 MPa)

- Hot-dip galvanization: 90% zinc purity, 200-400 micron thickness

- PVC/Powder coating: UV-resistant compounds meeting ASTM A641 standards

Test data shows 0.015mm/year corrosion rates in salt spray tests (ASTM B117), outperforming uncoated mesh by 8:1.

2023 Manufacturer Performance Benchmarking

| Vendor | Wire Gauge (mm) | Mesh Size (mm) | Lead Time | MOQ (m²) | Price Range ($/m²) |

|---|---|---|---|---|---|

| Manufacturer A | 1.6-4.0 | 12x12 to 100x100 | 14 days | 500 | 8.5-22.4 |

| Manufacturer B | 1.2-5.0 | 6x6 to 150x150 | 21 days | 1,000 | 7.8-19.9 |

| Manufacturer C | 2.0-6.0 | 25x25 to 200x200 | 10 days | 300 | 9.1-24.7 |

Tailored Solutions for Specific Applications

Customization options include:

- Aperture tolerance: ±3% to ±7%

- PVC color variants: 12 standard RAL codes

- Reinforced edges: 3mm-10mm hemming

- Hybrid coatings: PVC + anti-graffiti additives

Industrial users report 18-22% cost reduction through optimized mesh specifications.

Operational Efficiency Enhancements

Field data demonstrates:

• 40% faster installation vs. welded wire mesh

• 60% reduction in maintenance costs over 5-year period

• 0.35% maximum elongation under 500kg/m² loads

Verified Cross-Sector Implementations

| Industry | Mesh Type | Service Life | ROI Period |

|---|---|---|---|

| Wastewater Treatment | 2mm PVC/3mm Steel | 22 years | 3.8 years |

| Agricultural Fencing | 1.5mm Powder Coated | 18 years | 2.1 years |

PVC Coated Wire Mesh Manufacturers Pioneering Circular Economy

Industry leaders now achieve 92% material recovery rates through closed-loop recycling systems. Advanced manufacturing hubs utilize 34% renewable energy in production, aligning with UN Sustainable Development Goal 9.

(pvc coated wire mesh manufacturers)

FAQS on pvc coated wire mesh manufacturers

Q: What are the key advantages of choosing PVC coated wire mesh over other types?

A: PVC coated wire mesh offers superior corrosion resistance, enhanced durability in harsh environments, and a smoother surface finish compared to uncoated or galvanized alternatives. It’s ideal for outdoor and chemical-exposure applications.

Q: How does PVC coated steel mesh perform in extreme weather conditions?

A: PVC coated steel mesh withstands UV rays, moisture, and temperature fluctuations due to its protective polymer layer. This ensures long-term structural integrity and prevents rusting or degradation.

Q: What industries commonly use powder-coated steel wire mesh?

A: Powder-coated steel wire mesh is widely used in construction, agriculture, fencing, and industrial safety due to its aesthetic appeal, weather resistance, and customizable color options.

Q: How do I select a reliable PVC coated wire mesh manufacturer?

A: Look for manufacturers with ISO certifications, proven expertise in polymer coatings, and customized production capabilities. Client testimonials and sample testing further ensure quality compliance.

Q: Can PVC and powder-coated steel mesh be used interchangeably?

A: While both provide corrosion protection, PVC coating is thicker and better for abrasive environments, whereas powder coating offers finer finishes and is suited for indoor or decorative applications.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025