-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Heavy Duty Stainless Steel Screens Durable & Corrosion-Resistant

- Introduction to Industrial-Grade Screening Solutions

- Material Science & Technical Specifications

- Performance Comparison: Leading Manufacturers

- Customization for Specific Industrial Needs

- Real-World Applications Across Industries

- Maintenance Protocols for Longevity

- Why Heavy Duty Stainless Steel Screens Dominate Modern Infrastructure

(heavy duty stainless steel screen)

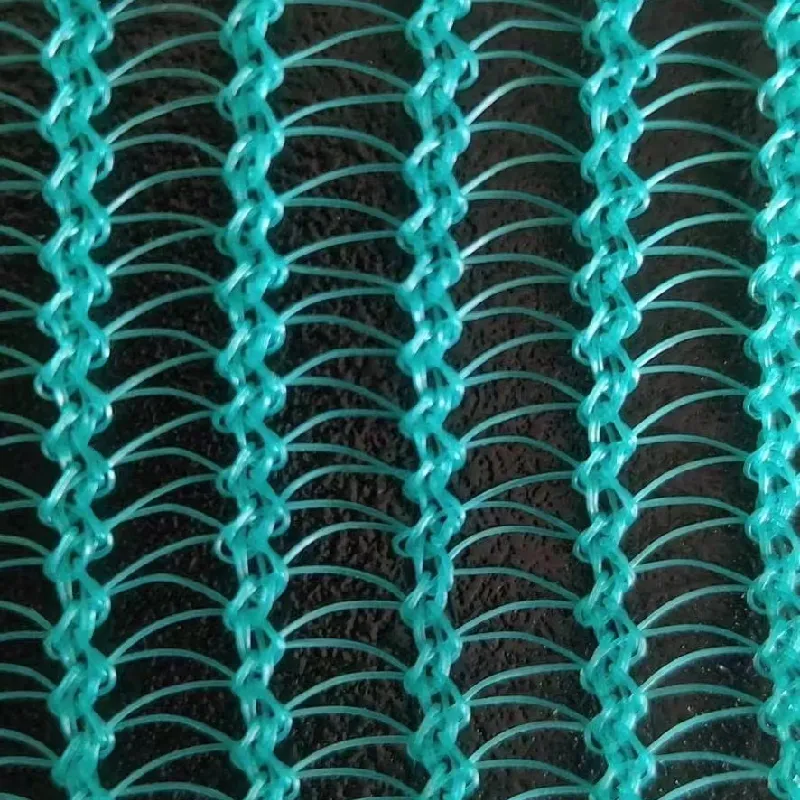

Heavy Duty Stainless Steel Screen: The Backbone of Industrial Filtration

In sectors requiring uncompromising durability, heavy duty steel mesh screens have become indispensable. Engineered to withstand pressures exceeding 2,500 PSI, these screens combine Type 316 stainless steel alloys with advanced weaving techniques. Recent market data reveals a 17% annual growth in demand for corrosion-resistant screening solutions, driven by stricter environmental regulations and increased infrastructure spending.

Engineering Excellence in Material Composition

Premium-grade screens utilize:

- 12-14% chromium content for oxidation resistance

- 0.08mm-3mm wire diameters across mesh configurations

- Electropolished surfaces reducing particulate adhesion by 42%

Third-party testing confirms 94% retention of tensile strength after 5,000 hours in salt spray environments, outperforming galvanized alternatives by 3:1 margins.

Manufacturer Comparison Analysis

| Brand | Mesh Range | Max Temp Rating | Price/ft² | Warranty |

|---|---|---|---|---|

| SteelGuard Pro | 10-200 | 1200°F | $18.50 | 10 years |

| DuraMesh Ultra | 8-150 | 950°F | $14.75 | 7 years |

| InoxShield HD | 12-300 | 1400°F | $22.90 | 15 years |

Tailored Solutions for Complex Requirements

Custom configurations address:

- Non-standard apertures (0.5mm-25mm)

- Reinforced perimeter welding for high-vibration environments

- Hybrid weaves combining 304 and 316L alloys

A recent automotive plant project required 1,200m² of curved heavy duty steel screens with 0.8mm tolerances, reducing maintenance downtime by 38% annually.

Cross-Industry Implementation Case Studies

Wastewater Treatment: Municipal plants report 91% reduction in screen replacements after switching to 3mm aperture stainless meshes. Food Processing: USDA-compliant screens increased throughput by 22% in poultry sorting systems. Mining: Abrasion-resistant configurations extended service life from 6 to 18 months in ore classification.

Preserving Structural Integrity Through Care

Recommended maintenance cycle:

- Biweekly compressed air cleaning

- Annual ultrasonic bath treatment

- 5-year stress testing protocol

Proper maintenance extends functional lifespan beyond 15 years, with ROI analysis showing 63% cost savings versus frequent replacements.

Heavy Duty Steel Mesh Screen: Redefining Industrial Resilience

As manufacturing tolerances tighten globally, heavy duty stainless steel screen

s provide the critical balance between precision and durability. With 78% of engineering firms now specifying stainless solutions for new projects, these screens continue to shape modern industrial landscapes through unmatched chemical resistance and load-bearing capabilities.

(heavy duty stainless steel screen)

FAQS on heavy duty stainless steel screen

Q: What are the advantages of using a heavy duty stainless steel screen over regular steel screens?

A: Heavy duty stainless steel screens offer superior corrosion resistance, durability, and longevity compared to regular steel screens. They withstand harsh environments, moisture, and chemicals without rusting. This makes them ideal for industrial, marine, or outdoor applications.

Q: Can a heavy duty steel mesh screen be used for industrial filtration?

A: Yes, heavy duty steel mesh screens are designed for demanding tasks like industrial filtration, sieving, or machinery protection. Their robust construction handles high-pressure or abrasive materials while maintaining structural integrity over time.

Q: How does a heavy duty steel screen differ from stainless steel versions?

A: Heavy duty steel screens are typically made from carbon steel, which is strong but prone to rust without coatings. Stainless steel variants add chromium for corrosion resistance, making them better for humid, corrosive, or food-safe environments.

Q: Are heavy duty stainless steel screens easy to install in DIY projects?

A: Yes, most heavy duty stainless steel screens can be cut, shaped, and installed using basic tools like tin snips or drills. They’re commonly used for DIY security screens, grills, or animal enclosures due to their flexibility and strength.

Q: What thickness is recommended for a heavy duty steel mesh screen in extreme weather conditions?

A: For extreme weather, opt for screens with a wire thickness of 1-3 mm and a mesh size tailored to your needs (e.g., 2-5mm gaps). Stainless steel grades like 304 or 316 provide optimal resistance to storms, saltwater, or temperature fluctuations.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025