-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

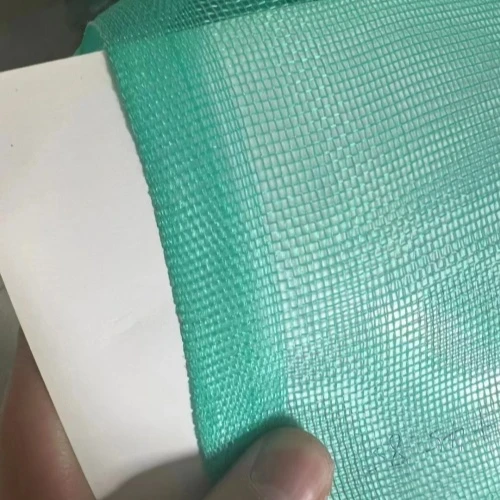

galvanized steel grid

The Versatility and Benefits of Galvanized Steel Grids

Galvanized steel grids have become an integral part of various industrial, commercial, and residential applications. Their unique properties, including corrosion resistance, strength, and durability, make them a preferred choice in many projects. In this article, we will explore what galvanized steel grids are, their manufacturing process, benefits, and applications, underscoring their importance in modern construction and infrastructure.

What is Galvanized Steel?

Galvanized steel refers to steel that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization not only enhances the lifespan of the steel but also adds to its structural integrity. Galvanized steel can come in various forms, but one of the most commonly used is the steel grid. These grids are created by welding or weaving steel bars, resulting in a mesh-like structure that offers both strength and lightweight properties.

Manufacturing Process

The manufacturing process of galvanized steel grids generally involves several key steps

1. Material Selection High-quality steel is selected based on the intended use of the grid. This usually involves considering factors such as strength, ductility, and the environment where the grid will be utilized.

2. Grid Formation The selected steel is then formed into a grid pattern either through welding (for welded grids) or weaving (for woven grids). This creates a stable structure capable of supporting significant loads while allowing for proper drainage and airflow.

3. Galvanization After the grid has been formed, it undergoes the galvanization process. The most common method is hot-dip galvanization, where the grid is submerged in molten zinc. This ensures that the zinc adheres thoroughly to the steel, forming a protective barrier against rust and corrosion.

4. Quality Inspection After galvanization, the grids are subjected to rigorous quality inspections to ensure they meet industry standards. This may involve tests for coating thickness, adherence, and overall structural integrity.

Benefits of Galvanized Steel Grids

galvanized steel grid

Galvanized steel grids offer numerous advantages that make them an appealing option for various applications

1. Corrosion Resistance The primary benefit of galvanization is its corrosion resistance. The zinc coating acts as a sacrificial layer, meaning it will corrode before the underlying steel, thus prolonging the life of the grid.

2. Durability Galvanized steel grids can withstand harsh environmental conditions, including extreme temperatures, humidity, and exposure to chemicals. This durability makes them suitable for use in a variety of settings, including outdoor installations and industrial environments.

3. Cost-Effectiveness While the initial cost of galvanized steel grids may be higher than untreated steel, their durability and low maintenance requirements lead to cost savings over time. They do not need frequent replacement or extensive maintenance, which can significantly reduce total cost of ownership.

4. Lightweight and Strong Despite their lightweight nature, galvanized steel grids offer high strength-to-weight ratios. This makes them ideal for projects where weight is a concern, such as elevated platforms or access walkways.

5. Versatility These grids can be used in numerous applications, including flooring, grating, fencing, and scaffolding. Their adaptability allows architects and engineers to incorporate them into various designs and structures seamlessly.

Applications of Galvanized Steel Grids

Galvanized steel grids are utilized in a wide range of applications

- Industrial Flooring They are often used in factories and warehouses for flooring solutions that are durable and allow for adequate drainage. - Walkways and Platforms Safety is paramount in construction and industrial settings, making galvanized steel grids an excellent choice for walkways and elevated platforms. - Agricultural Uses In agriculture, they serve as flooring for livestock barns and as support structures for various farm equipment. - Environmental Applications Galvanized steel grids are also used in water treatment plants and drainage systems due to their ability to resist corrosion from chemicals and moisture.

Conclusion

In summary, galvanized steel grids are a vital component in modern construction and industries due to their exceptional characteristics of strength, durability, and corrosion resistance. Their effectiveness in various applications underscores their growing popularity. As industries continue to seek solutions that offer longevity and cost-efficiency, galvanized steel grids will undoubtedly play a crucial role in shaping the future of building materials.

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025