-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Concrete Reinforcement Steel Grids for Enhanced Structural Integrity and Durability

Understanding Concrete Reinforcement Steel Mesh

Concrete has long been a fundamental material in construction due to its strength, durability, and versatility. However, one of the inherent weaknesses of concrete is its tensile strength. Concrete can withstand significant compressive forces, but it is relatively weak under tensile stress. This limitation is where concrete reinforcement steel mesh comes into play.

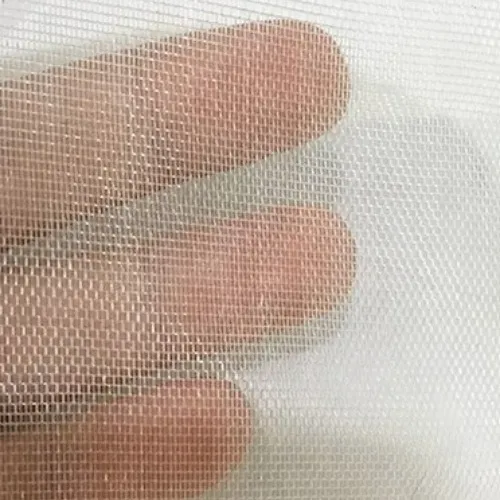

Concrete reinforcement steel mesh, commonly referred to as wire mesh or rebar mesh, serves as a key component in enhancing the structural integrity of concrete. Made from high-strength steel wire, this mesh is designed to distribute loads and provide additional tensile strength to concrete structures, minimizing the risk of cracking and failure.

The Importance of Reinforcement

The primary purpose of reinforcement in concrete is to improve its overall performance. When loads are applied to a concrete structure, it experiences both compressive forces (pushing together) and tensile forces (pulling apart). While concrete excels in bearing compressive loads, it is prone to cracking when subjected to tension. By incorporating steel mesh into the concrete, engineers can counteract this weakness.

Reinforcement steel mesh comes in a variety of sizes and configurations, making it adaptable to different construction needs. The mesh is typically laid out in a grid pattern and can be easily cut or bent to accommodate specific designs. It is often used in a wide range of applications, including slabs, walls, and foundations, and is particularly beneficial in areas prone to seismic activity and heavy loading.

Types of Reinforcement Mesh

There are two main types of reinforcement mesh welded wire mesh and welded rebar mesh.

1. Welded Wire Mesh This type consists of a series of longitudinal and transverse wires that are welded together at intersections, creating a grid-like structure. It is widely used in slabs and pavements due to its ease of installation and uniform strength distribution. The spacing of the wires can be adjusted based on the structural demands.

concrete reinforcement steel mesh

2. Welded Rebar Mesh This type is made from steel bars (rebar) welded to form a grid. It is typically used in heavily loaded structures where higher tensile strength is required. The larger diameter of the rebar provides added strength and stability, making it an excellent choice for construction projects that must endure significant stress.

Benefits of Using Steel Mesh

The incorporation of steel mesh in concrete construction offers several advantages

- Increased Strength Reinforcement mesh significantly increases the tensile strength of concrete, reducing the likelihood of cracks and structural failures. - Crack Control By distributing tensile forces evenly, steel mesh helps to control cracking, which can compromise the integrity of a structure over time. - Flexibility in Design Steel mesh can be easily customized to meet the specific needs of each project, allowing for versatility in design. - Cost-Effective Although there is an upfront cost associated with purchasing and installing reinforcement mesh, the long-term savings due to reduced maintenance and increased durability outweigh the initial investment.

Installation Considerations

For optimal performance, proper installation of steel mesh is critical. It is crucial to ensure that the mesh is securely placed in the correct position within the concrete pour. It should be elevated slightly off the ground using supports, ensuring that it is effectively embedded within the concrete matrix. Improper placement can lead to reduced effectiveness, negating the benefits of using reinforcement mesh.

Conclusion

Concrete reinforcement steel mesh is an essential component in modern construction, enhancing the strength and stability of concrete structures. Its ability to counteract the tensile weakness of concrete, along with its flexible design options and cost-effectiveness, makes it a favored choice among engineers and builders. As construction techniques continue to evolve, the use of reinforcement steel mesh will remain a cornerstone in the quest for durable, resilient infrastructure.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025