-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

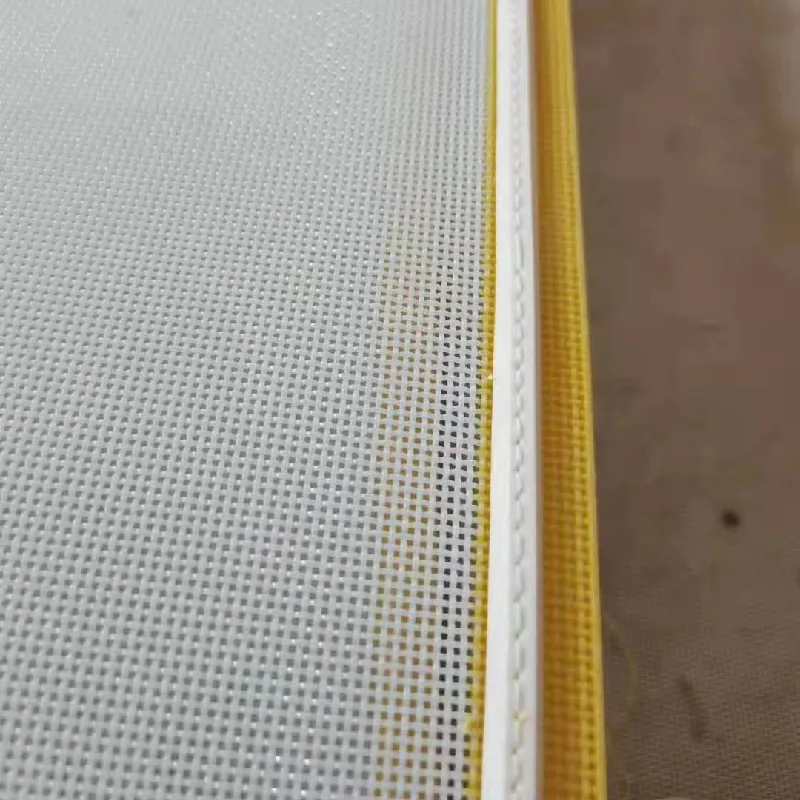

ss filter

Understanding SS Filter Technology An Overview

In the world of filtration technologies, SS (Stainless Steel) filters have emerged as a vital solution for various industries, including food and beverage, pharmaceuticals, and chemical processing. These filters leverage the unique properties of stainless steel to ensure the efficient separation of particles from liquids and gases. This article delves into the mechanics of SS filter technology, its advantages, applications, and its role in enhancing product quality and safety.

What is an SS Filter?

An SS filter is a type of filtration system made from stainless steel, which is known for its corrosion resistance, strength, and durability. These filters can come in various designs, including bag filters, cartridge filters, or even as part of a larger filtration system. The primary function of an SS filter is to remove impurities and solids from a process stream, thereby enhancing the purity of the final product.

The design of an SS filter can vary widely depending on the specific application. Some may use a simple mesh screen, while more complex systems may feature multiple layers of filtration media to capture a wider range of particle sizes. Regardless of the design, the core principle remains the same to separate unwanted material while allowing clean liquid or gas to pass through.

Advantages of SS Filters

1. Durability Stainless steel is inherently resilient against harsh chemicals and extreme temperatures, which makes it an ideal material for filters used in industrial applications. This durability translates to a longer lifespan for the filter, reducing the need for frequent replacements and maintenance.

2. Cleanability SS filters can be easily cleaned and sterilized, making them particularly valuable in applications where cleanliness is paramount, such as in the food and pharmaceutical industries. Their non-porous surface does not harbor bacteria or contaminants, facilitating easier sanitation procedures.

3. Customization These filters can be tailored to specific needs, allowing for adjustments in size, mesh density, and other parameters. This customization ensures optimal performance for various applications, from water treatment to chemical processing.

4. Sustainability Given their longevity and recyclability, SS filters have a lower environmental impact compared to disposable alternatives. This aspect aligns with growing industry trends toward sustainability and reducing waste.

5. Cost-Effectiveness While the initial investment in stainless steel filters may be higher than traditional filters, the long-term savings due to lower replacement rates and reduced downtime can make them more cost-effective over time.

ss filter

Applications of SS Filters

The versatility of SS filters means they are used in a wide array of industries

- Food and Beverage In this sector, SS filters are essential for ensuring product purity and safety. They are used to filter liquids such as beer, wine, and juice, removing yeast, sediment, and other particles to achieve a clear product.

- Pharmaceuticals The pharmaceutical industry mandates stringent quality controls. SS filters play a crucial role in the production process by ensuring that the final products are free from contaminants that could compromise efficacy or safety.

- Chemical Processing SS filters are commonly employed to remove particulates from process streams, such as solvents, oils, and other chemicals, which helps to maintain the integrity of the final products.

- Water Treatment In water purification systems, SS filters ensure that drinking water meets regulatory standards by effectively removing harmful contaminants.

The Future of SS Filter Technology

With advancements in technology, the future of SS filter systems looks promising. Innovations in materials science and engineering techniques are set to enhance filter performance, efficiency, and sustainability further. The integration of smart technologies, such as IoT-enabled monitoring systems, will allow for better tracking of filter conditions and more proactive maintenance schedules.

Conclusion

SS filters are a cornerstone of modern filtration technology across various industries, offering numerous benefits in terms of durability, cleanability, and sustainability. As industries continue to prioritize cleanliness and product quality, the demand for advanced filtration solutions, including SS filters, is expected to grow. By investing in these systems, companies can improve operational efficiency, lower their environmental footprint, and ensure the safety and quality of their products. As we look to the future, SS filters are poised to play an even greater role in maintaining the high standards required in today’s fast-paced industrial landscape.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025