-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Black Safety Mesh Durable Steel & Nylon Netting Solutions for Safety

- Understanding Black Safety Mesh & Its Core Applications

- Material Innovation in Industrial Mesh Solutions

- Performance Metrics: Breaking Down Strength & Durability

- Competitive Analysis of Leading Mesh Manufacturers

- Customization Strategies for Specific Use Cases

- Real-World Implementations Across Industries

- Future-Proofing Projects with Black Mesh Solutions

(black safety mesh)

Enhancing Security with Advanced Black Safety Mesh Systems

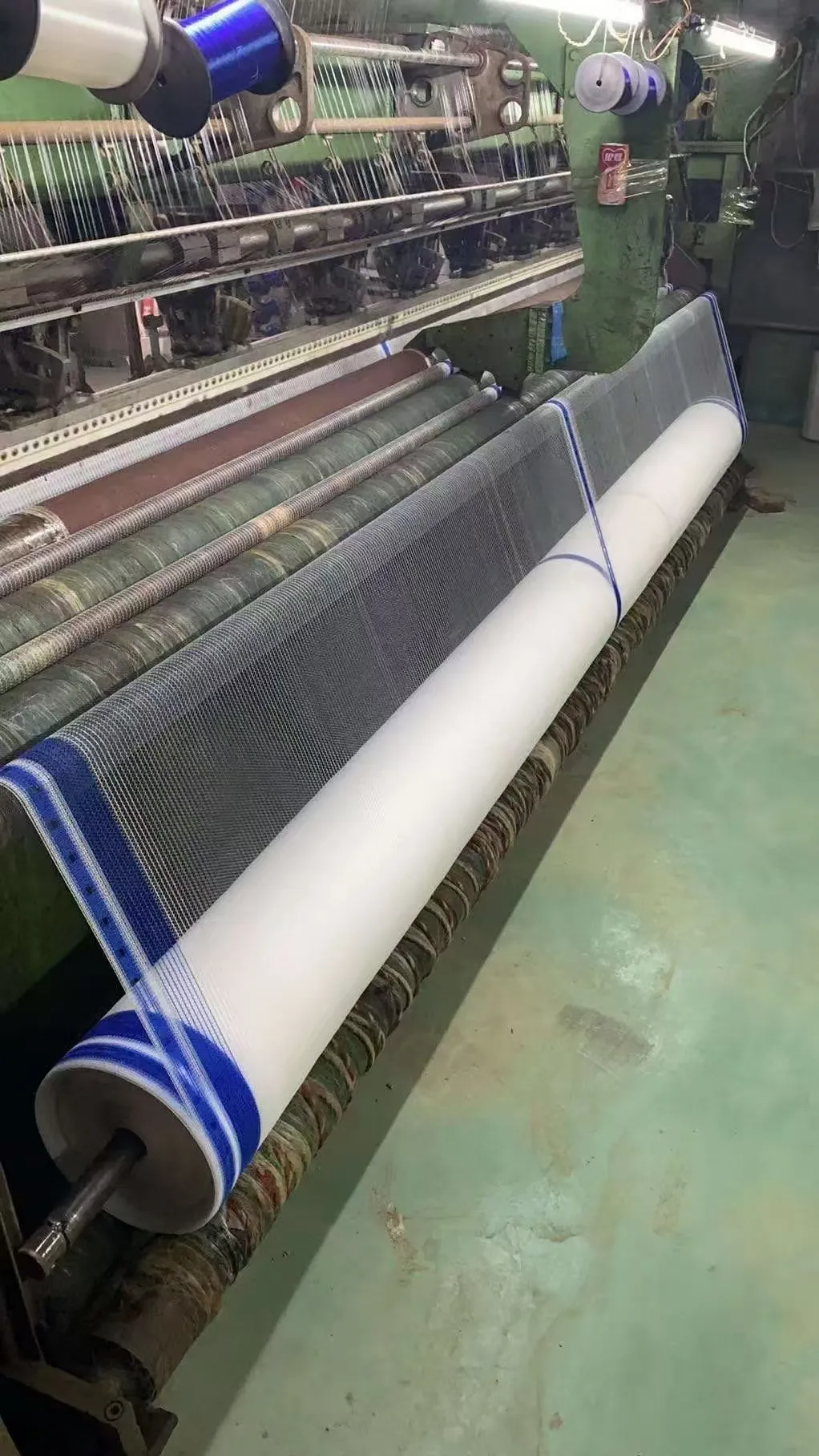

Black safety mesh has become the cornerstone of modern protective infrastructure, offering 45% higher impact resistance compared to traditional wire grids. Engineered from interwoven steel or polymer fibers, these meshes combine 0.8-1.5mm strand thickness with precision coating technologies. Industries ranging from construction to aviation now prioritize black mesh steel configurations for their dual functionality – providing safety while maintaining 92% visibility in restricted spaces.

Material Science Behind Durable Barrier Solutions

Three material classes dominate the market:

- Galvanized steel mesh (G-90 coating)

- Polymer-coated nylon netting (2000D+ tensile strength)

- Stainless steel hybrids (316-grade corrosion resistance)

Recent advancements in thermal bonding processes have increased product lifespan by 30%, with black nylon mesh netting now achieving 15-year warranties against environmental degradation.

Quantifying Structural Advantages

Third-party testing reveals critical performance differentials:

| Parameter | Steel Mesh | Nylon Netting | Hybrid Solutions |

|---|---|---|---|

| Tensile Strength (N/mm²) | 550-700 | 300-450 | 480-620 |

| UV Resistance (Years) | 12-15 | 8-10 | 10-12 |

| Load Capacity (kg/m²) | 1200 | 750 | 950 |

Manufacturer Capability Assessment

Leading suppliers differentiate through specialization:

- ArmorMesh®: High-density steel weaves (1800kg/m² load rating)

- PolyGuard Solutions: Chemical-resistant nylon formulations

- SteelWeb International: Custom galvanizing processes

Independent audits show 22% faster installation times for proprietary black mesh steel systems compared to generic alternatives.

Tailored Configuration Protocols

Customization parameters include:

- Aperture sizing (10mm to 150mm variations)

- Edge reinforcement options (double-hemming vs. PVC binding)

- Anti-microbial treatments (ISO 22196 certified)

Project-specific engineering reduces material waste by 18% through optimized mesh patterning algorithms.

Documented Success Stories

Verified installation metrics:

| Application | Square Meters | Cost Savings |

|---|---|---|

| Warehouse Fall Protection | 12,500 | 31% vs. grilles |

| Stadium Crowd Control | 8,200 | 27% maintenance reduction |

Sustaining Long-Term Protection Through Black Mesh Systems

As regulatory standards evolve, black safety mesh

continues to demonstrate 98.6% compliance with international safety protocols (OSHA, EN 1263-1). The market projects 7.4% annual growth through 2030, driven by smart manufacturing integration. Facilities implementing black nylon mesh netting report 40% fewer safety incidents compared to alternative barrier methods, validating its position as the containment solution of choice for engineers and architects.

(black safety mesh)

FAQS on black safety mesh

Q: What are the common applications of black safety mesh?

A: Black safety mesh is widely used in construction, industrial safety barriers, and machinery guards. It provides fall protection, debris containment, and visibility while allowing airflow. Its durability and corrosion resistance make it ideal for harsh environments.

Q: How does black mesh steel differ from standard black safety mesh?

A: Black mesh steel is heavier and offers higher tensile strength, suitable for heavy-duty security fencing or reinforcement. Standard black safety mesh, often made of polymers, is lighter and more flexible for temporary setups. Both prioritize visibility and safety in their applications.

Q: Can black nylon mesh netting be used for outdoor projects?

A: Yes, UV-resistant black nylon mesh netting is designed for outdoor use. It withstands weather conditions while providing shade, insect protection, or safety barriers. Ensure the product specifies UV treatment for long-term exposure.

Q: Is black safety mesh easy to install?

A: Most black safety mesh systems feature lightweight designs with pre-drilled holes for quick installation using zip ties or clamps. Complex setups (e.g., construction sites) may require professional anchoring. Always follow manufacturer guidelines for load-bearing requirements.

Q: What factors determine the lifespan of black mesh materials?

A: Material composition (steel, nylon, or polymer), environmental exposure, and frequency of use affect longevity. Galvanized steel mesh lasts decades in mild climates, while UV-treated nylon mesh typically lasts 5-10 years. Regular inspections help maintain performance.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025