-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

mesh manufacturing

The Future of Mesh Manufacturing Innovations and Applications

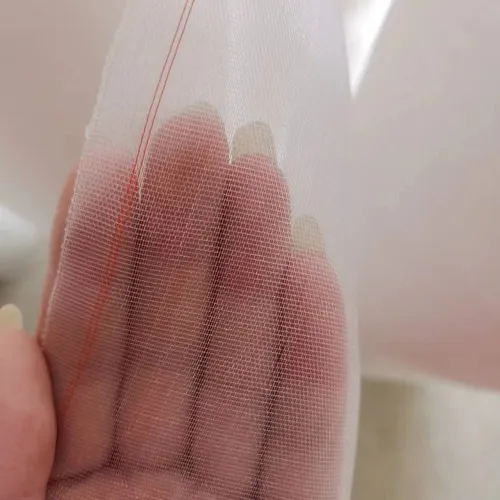

Mesh manufacturing, an integral aspect of modern engineering and design, refers to the process of creating various mesh structures using different materials and techniques. This technology has garnered attention across a multitude of industries due to its unique properties and versatile applications. From textiles to construction, the ability to produce lightweight, durable, and functional mesh products is transforming how we think about manufacturing and product design.

At its core, mesh manufacturing involves the interlacing of fibers or materials to create a network of interconnected strands. This results in a product that possesses remarkable flexibility, strength, and breathability. These attributes make mesh products ideal for a wide range of applications, including but not limited to sportswear, filtration systems, architectural elements, and medical devices.

One of the most significant sectors benefiting from advancements in mesh manufacturing is the textile industry. Clothing manufacturers are increasingly incorporating mesh fabrics into their designs for athletic wear, offering increased ventilation and moisture-wicking properties. This has led to the rise of performance-oriented garments that enhance athletic performance by keeping the body dry and comfortable during physical activities. Furthermore, the aesthetic appeal of mesh has led to its use in casual fashion lines, making it a staple in contemporary wardrobe choices.

In construction, mesh materials play a critical role in reinforcing structures. Steel mesh is commonly used in concrete applications to enhance tensile strength and durability. The use of geogrid mesh in civil engineering projects aids in soil stabilization and erosion control, showcasing the importance of mesh in ensuring safe and stable infrastructure. Innovations in 3D printing technology have also opened new avenues for creating complex mesh designs that were previously impossible to manufacture, allowing for innovative architectural solutions.

mesh manufacturing

The medical field has seen remarkable advancements through mesh manufacturing as well. Surgical mesh, made of synthetic or biological materials, is commonly used to support weakened tissues in various procedures, including hernia repairs. The development of bioresorbable meshes has paved the way for improved patient outcomes, as these materials gradually break down in the body, eliminating the need for a second surgical procedure to remove the implant. This innovation exemplifies how mesh technology is enhancing patient care and recovery processes.

As we look towards the future, the sustainability of mesh manufacturing is becoming a paramount concern. Traditional manufacturing practices often lead to substantial waste, but new techniques, such as additive manufacturing and closed-loop systems, are being developed to minimize environmental impact. The shift towards using recycled materials in mesh production not only reduces waste but also caters to a growing consumer demand for eco-friendly products. Companies that embrace sustainable practices in mesh manufacturing are likely to gain a competitive edge in the market, appealing to environmentally conscious consumers.

Moreover, digital technology is revolutionizing the way mesh products are designed and manufactured. Computer-aided design (CAD) software allows for precise modeling of complex mesh structures, enabling engineers and designers to visualize and adjust their creations before production. The integration of artificial intelligence (AI) is also influencing mesh manufacturing, optimizing processes and predicting material performance to reduce costs and improve efficiency.

In conclusion, the realm of mesh manufacturing is evolving dramatically, driven by technological advancements and an increasing demand for innovative, sustainable products. Its applications span across various industries, showcasing its versatility and importance in modern manufacturing. As we continue to explore new materials, techniques, and technologies, the potential for mesh manufacturing will only expand, leading to new solutions and possibilities for the future. As industries adapt to these changes, we can expect mesh manufacturing to play a pivotal role in shaping the landscape of engineering, design, and sustainability in the years to come.

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025