-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

veebr. . 16, 2025 15:40

Back to list

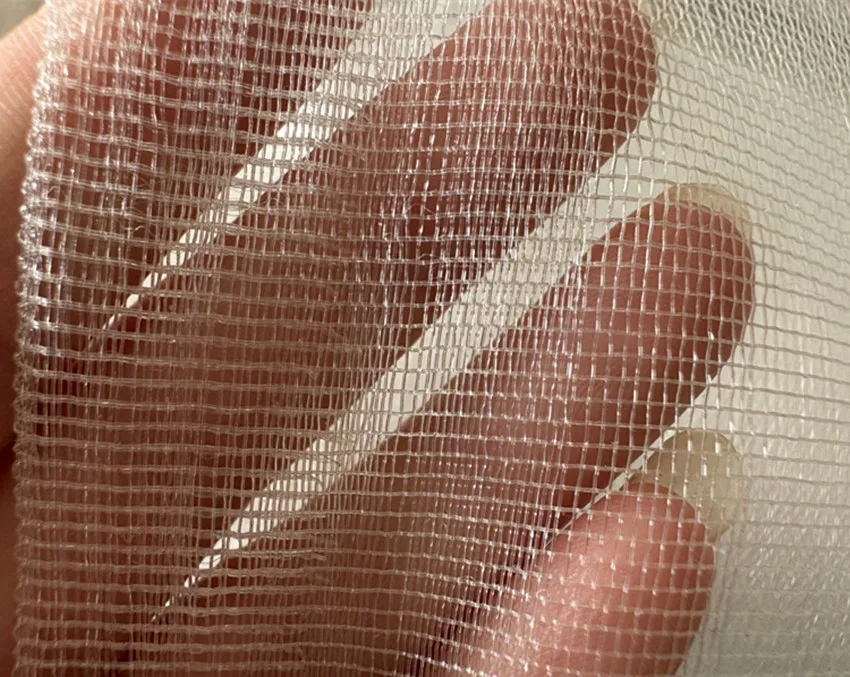

welded wire mesh

Welded steel mesh, a crucial innovation in the construction and engineering industries, plays a pivotal role in ensuring the robustness and stability of various structures. Crafted through an intricate process of welding intersecting steel wires or rods at their junctions, this mesh delivers unmatched strength, making it a favorite among professionals for a multitude of applications. Beyond its fundamental use in reinforcement, welded steel mesh has transformed the way we tackle various construction challenges, thanks to its exceptional properties and versatility.

Trust in the use of welded steel mesh is further bolstered by extensive research and development that continue to refine its properties. The industry is witnessing advancements in coating technologies, such as galvanization, that enhance the corrosion resistance of the mesh, broadening its application in different environmental conditions. These protective coatings ensure long-term durability and reduce maintenance costs, adding another layer of reliability. Authoritative industry standards and certifications regulate the production of welded steel mesh, ensuring it meets rigorous safety and quality benchmarks. Professionals seeking to implement this material in their projects are assured of its compliance with international engineering norms, further solidifying its credibility. Professionals and users are also provided with comprehensive guidance and support when choosing the correct type of welded steel mesh for specific projects. Technical documents, case studies, and manufacturer expertise are readily available to aid in making informed decisions, from selecting the appropriate wire gauge to understanding load-bearing capacities. In conclusion, welded steel mesh is a cornerstone in modern construction, offering unmatched strength, efficiency, and reliability. As technology advances, its role will undoubtedly expand, driven by ongoing innovations and increasingly stringent standards. Its proven track record and the continuous development of its features make it a trustworthy option for architects and engineers striving for excellence in building strong, long-lasting structures. Whether you're tackling a small-scale project or embarking on monumental construction, welded steel mesh stands as a testament to precision engineering and enduring quality.

Trust in the use of welded steel mesh is further bolstered by extensive research and development that continue to refine its properties. The industry is witnessing advancements in coating technologies, such as galvanization, that enhance the corrosion resistance of the mesh, broadening its application in different environmental conditions. These protective coatings ensure long-term durability and reduce maintenance costs, adding another layer of reliability. Authoritative industry standards and certifications regulate the production of welded steel mesh, ensuring it meets rigorous safety and quality benchmarks. Professionals seeking to implement this material in their projects are assured of its compliance with international engineering norms, further solidifying its credibility. Professionals and users are also provided with comprehensive guidance and support when choosing the correct type of welded steel mesh for specific projects. Technical documents, case studies, and manufacturer expertise are readily available to aid in making informed decisions, from selecting the appropriate wire gauge to understanding load-bearing capacities. In conclusion, welded steel mesh is a cornerstone in modern construction, offering unmatched strength, efficiency, and reliability. As technology advances, its role will undoubtedly expand, driven by ongoing innovations and increasingly stringent standards. Its proven track record and the continuous development of its features make it a trustworthy option for architects and engineers striving for excellence in building strong, long-lasting structures. Whether you're tackling a small-scale project or embarking on monumental construction, welded steel mesh stands as a testament to precision engineering and enduring quality.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025