-

afrikkalainen

afrikkalainen -

albanialainen

albanialainen -

amhara

amhara -

arabialainen

arabialainen -

armenialainen

armenialainen -

Azerbaidžani

Azerbaidžani -

baski

baski -

valkovenäläinen

valkovenäläinen -

bengali

bengali -

bosnialainen

bosnialainen -

bulgarialainen

bulgarialainen -

katalaani

katalaani -

Cebuano

Cebuano -

Kiina

Kiina -

Korsikalainen

Korsikalainen -

Kroatia

Kroatia -

Tšekki

Tšekki -

Tanskan kieli

Tanskan kieli -

Hollannin kieli

Hollannin kieli -

Englanti

Englanti -

esperanto

esperanto -

Virolainen

Virolainen -

Suomalainen

Suomalainen -

Ranskan kieli

Ranskan kieli -

friisi

friisi -

Galicialainen

Galicialainen -

Georgian

Georgian -

Saksan kieli

Saksan kieli -

kreikkalainen

kreikkalainen -

gudžarati

gudžarati -

Haitin kreoli

Haitin kreoli -

hausa

hausa -

havaijilainen

havaijilainen -

heprealainen

heprealainen -

Ei

Ei -

Miao

Miao -

Unkarin kieli

Unkarin kieli -

islantilainen

islantilainen -

igbo

igbo -

Indonesialainen

Indonesialainen -

irlantilainen

irlantilainen -

italialainen

italialainen -

japanilainen

japanilainen -

jaavalainen

jaavalainen -

kannada

kannada -

kazakki

kazakki -

khmerit

khmerit -

Ruanda

Ruanda -

Korealainen

Korealainen -

kurdi

kurdi -

Kirgisia

Kirgisia -

TB

TB -

Latina

Latina -

Latvialainen

Latvialainen -

liettualainen

liettualainen -

luxemburgilainen

luxemburgilainen -

makedonialainen

makedonialainen -

Madagaskari

Madagaskari -

malaiji

malaiji -

malajalami

malajalami -

maltalainen

maltalainen -

maori

maori -

marathi

marathi -

mongolialainen

mongolialainen -

Myanmar

Myanmar -

Nepali

Nepali -

Norjan kieli

Norjan kieli -

Norjan kieli

Norjan kieli -

Oksitaani

Oksitaani -

pashto

pashto -

persialainen

persialainen -

Kiillottaa

Kiillottaa -

Portugalin kieli

Portugalin kieli -

Punjabi

Punjabi -

romanialainen

romanialainen -

Venäjän kieli

Venäjän kieli -

samoalainen

samoalainen -

Skotlannin gaeli

Skotlannin gaeli -

serbia

serbia -

Englanti

Englanti -

Shona

Shona -

Sindhi

Sindhi -

sinhala

sinhala -

Slovakian

Slovakian -

slovenialainen

slovenialainen -

somali

somali -

Espanja

Espanja -

sundalainen

sundalainen -

swahili

swahili -

Ruotsin kieli

Ruotsin kieli -

Tagalog

Tagalog -

tadžiki

tadžiki -

tamili

tamili -

tatari

tatari -

telugu

telugu -

thaimaalainen

thaimaalainen -

turkkilainen

turkkilainen -

Turkmenistan

Turkmenistan -

ukrainalainen

ukrainalainen -

urdu

urdu -

uiguuri

uiguuri -

uzbekki

uzbekki -

vietnam

vietnam -

Walesin

Walesin -

auta

auta -

jiddish

jiddish -

joruba

joruba -

zulu

zulu

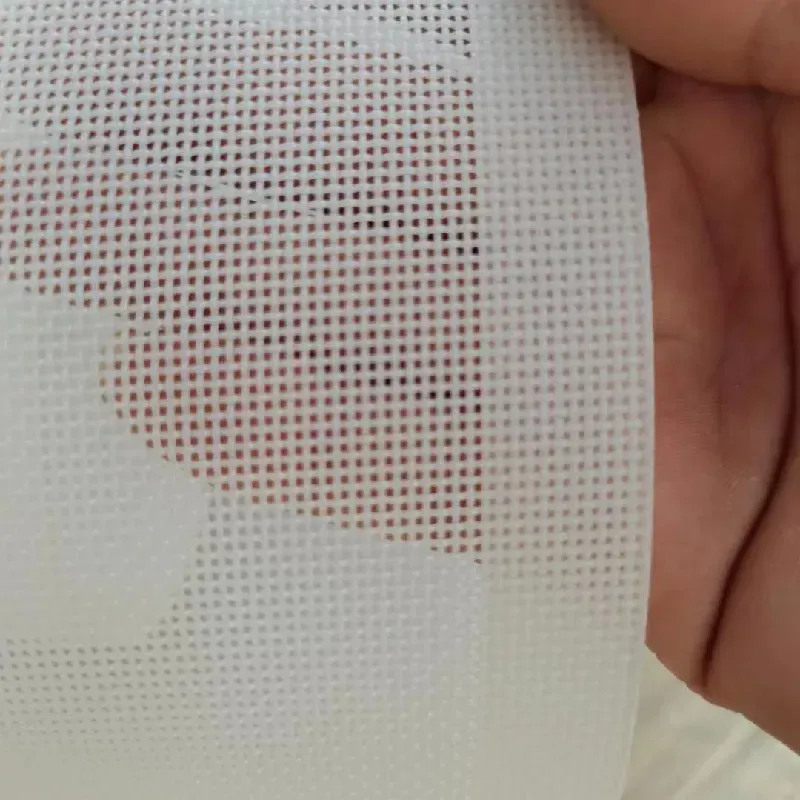

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial Applications

In a world that increasingly depends on materials that are both versatile and resilient, nylon mesh netting stands out as a solution that bridges functionality and innovation. Whether you're seeking a solution for industrial filtration, agricultural sorting, sports equipment, marine applications, or custom packaging, the adaptability of nylon verkko is unmatched.

What truly sets nylon verkko apart is its balance of durability and flexibility. With the ability to be shaped, sealed, or customized for countless needs, this mesh offers a long-lasting and cost-effective solution that has quietly become indispensable across sectors.

Thick Nylon Netting: Toughness That Meets Flexibility

At the core of high-demand applications is thick nylon netting—a heavy-duty variant engineered for resilience. Unlike thinner meshes that may fray or collapse under weight, thick netting is specifically designed to withstand mechanical stress, environmental factors, and repeated handling. Whether it’s used in outdoor settings, for cargo protection, industrial screening, or high-impact sports barriers, this netting provides unmatched tensile strength and tear resistance.

The manufacturing process involves tightly woven or knitted nylon fibers treated for extra durability. This gives the mesh the capacity to absorb force, resist punctures, and maintain shape without sagging or stretching excessively. Moreover, thick nylon netting can be UV-stabilized or flame-retardant, adding layers of security in safety-critical settings like construction sites or marine environments.

This product can also be processed into annular mesh belts or edge-sealed configurations, ensuring longevity even under heavy use. This makes it a favorite for conveyor belts in food processing and drying systems in textile or agriculture industries.

Nylon Mesh: Customizable Precision for Any Industry

In addition to its industrial strength, nylon verkko distinguishes itself by offering unmatched customization. It can be processed into various mesh sizes—from micro-perforated screens for filtration and sifting, to large-aperture nets for aquaculture or sports nets. These meshes are not just made to last—they are made to suit.

Clients can request mesh bags in any shape, tailored for their application—from drawstring bags for produce, to flat pouches for medical or automotive components. Thanks to nylon’s natural flexibility and high melting point, nylon verkko retains its form even after high-pressure sterilization, chemical exposure, or temperature fluctuation.

A key advantage is the material’s edge-processing capability. With options such as sewn hems, glue-sealed edges, or thermal brushing, the mesh can be adapted to prevent fraying or unraveling—particularly important in reusable or high-friction scenarios. This process ensures product integrity without the need for complex reinforcements.

Whether you are packaging granular items, building filtration systems, or requiring semi-permeable barriers, the precision and adaptability of nylon verkko allows for unparalleled industrial customization.

Nylon Netting: Lightweight Yet Reliable Performance

While thick versions provide heavy-duty support, lightweight nylon verkko is widely used for less intensive yet equally important applications. From bird-proofing in agriculture to garment finishing in fashion, nylon netting delivers a lightweight, breathable, and adaptable solution.

Its aesthetic versatility is also an advantage. Available in multiple colors, densities, and patterns, nylon verkko can be integrated into product design—whether for branding in packaging, visibility in sports, or discreteness in security applications. Despite its lightness, the tensile strength remains sufficient for consistent performance in medium-duty scenarios.

Nylon netting's resistance to mildew, rot, and most chemicals makes it ideal for both indoor and outdoor use. It holds up in wet conditions and dries quickly, making it suitable for aquariums, pet enclosures, laundry bags, and even lightweight fencing solutions.

With support for prototyping and small-batch production, businesses can test and validate designs using nylon verkko before scaling up—an invaluable feature in product development pipelines.

Nylon Net: The Multi-Industry Standard

As businesses continue to demand materials that can do more with less, the nylon net has emerged as the go-to solution across multiple sectors. Its strength-to-weight ratio, adaptability, and low production cost make it a favorite among OEMs, logistics companies, architects, designers, and hobbyists alike.

In agriculture, nylon net is used for plant protection, trellis support, and produce bagging. In retail, it's employed in mesh displays and reusable shopping bags. In marine environments, it offers durable fishing and crab nets that resist saltwater corrosion. Even in aerospace and automotive sectors, where weight reduction is crucial, nylon nets serve as lightweight dividers or cargo retainers.

What amplifies its utility is nylon’s inherent resistance to abrasion and temperature fluctuation. Whether stretched across metal frameworks or shaped into pockets and pouches, the nylon net maintains its integrity without stiffening, shrinking, or cracking under pressure.

Nylon Mesh Netting: Innovation You Can Customize

Above all, nylon mesh netting is an innovation built around your needs. Manufacturers offer support for proofing and prototyping, allowing you to refine your product before entering full-scale production. Need a square mesh for air filtration? A tubular mesh for packaging? A mesh belt with heat-sealed edges for high-speed drying? Nylon mesh netting can do it all.

The ability to process this product into annular belts, customized bags, or fitted mesh panels makes it a truly modular material. Industrial users appreciate that it can be laser-cut or die-cut into complex shapes, while designers value its dye-ability and surface texture for consumer-facing products.

What’s more, nylon mesh netting is easy to maintain, washable, and recyclable—features that appeal to environmentally conscious brands and organizations. And with options for FDA-approved food-safe grades or medical sterilization compatibility, it can be trusted in regulated industries as well.

In a landscape where performance and adaptability define success, nylon mesh netting proves itself as both the foundation and the future of material design.

Nylon Mesh Netting FAQs

What applications are best suited for thick nylon netting?

Thick nylon netting is ideal for industrial and heavy-duty applications, including cargo nets, safety barriers, sports fencing, conveyor belts, and construction site protection. Its enhanced tensile strength and durability allow it to perform in high-impact, high-wear environments.

Can nylon mesh be customized for unique industrial uses?

Absolutely. Nylon mesh can be processed into specific shapes, mesh sizes, and edge styles. It supports glue-sealing, edge-brushing, and annular belt forming, making it adaptable for uses in filtration, sorting, packaging, and protective barriers.

How does nylon netting perform in outdoor environments?

Nylon netting is highly resistant to UV rays, moisture, mildew, and chemicals, making it an excellent choice for outdoor use in agriculture, marine applications, and exterior barriers. With proper treatment, it can maintain integrity in fluctuating weather conditions.

Is nylon net safe for use in food or medical applications?

Yes. Certain grades of nylon net are FDA-compliant and suitable for direct contact with food. It can also be sterilized for use in medical packaging, instruments, or storage. Always ensure you source from a supplier who provides certification for such applications.

What’s the difference between nylon mesh netting and standard plastic netting?

Unlike basic plastic netting, nylon mesh netting offers superior strength, flexibility, temperature resistance, and customizability. It lasts longer, withstands mechanical stress better, and can be tailored with edge treatments or coatings that extend its lifespan and broaden its usability.

-

Shipping Plastic Bags for Every NeedUutisetJul.24,2025

-

Safety Netting: Your Shield in ConstructionUutisetJul.24,2025

-

Plastic Mesh Netting for Everyday UseUutisetJul.24,2025

-

Nylon Netting for Every UseUutisetJul.24,2025

-

Mesh Breeder Box for Fish TanksUutisetJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityUutisetJul.24,2025