-

africain

africain -

albanais

albanais -

Amharique

Amharique -

arabe

arabe -

arménien

arménien -

azerbaïdjanais

azerbaïdjanais -

Basque

Basque -

biélorusse

biélorusse -

bengali

bengali -

bosniaque

bosniaque -

bulgare

bulgare -

catalan

catalan -

Cebuano

Cebuano -

Chine

Chine -

Corse

Corse -

croate

croate -

tchèque

tchèque -

danois

danois -

Néerlandais

Néerlandais -

Anglais

Anglais -

espéranto

espéranto -

estonien

estonien -

finlandais

finlandais -

Français

Français -

frison

frison -

Galicien

Galicien -

géorgien

géorgien -

Allemand

Allemand -

grec

grec -

Gujarati

Gujarati -

Créole haïtien

Créole haïtien -

haoussa

haoussa -

hawaïen

hawaïen -

hébreu

hébreu -

Non

Non -

Miao

Miao -

hongrois

hongrois -

islandais

islandais -

Igbo

Igbo -

indonésien

indonésien -

irlandais

irlandais -

italien

italien -

Japonais

Japonais -

Javanais

Javanais -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandais

Rwandais -

coréen

coréen -

kurde

kurde -

Kirghize

Kirghize -

tuberculose

tuberculose -

latin

latin -

letton

letton -

lituanien

lituanien -

luxembourgeois

luxembourgeois -

Macédonien

Macédonien -

malgache

malgache -

malais

malais -

Malayalam

Malayalam -

maltais

maltais -

Maori

Maori -

Marathi

Marathi -

mongol

mongol -

Birmanie

Birmanie -

Népalais

Népalais -

norvégien

norvégien -

norvégien

norvégien -

Occitan

Occitan -

pachtou

pachtou -

persan

persan -

polonais

polonais -

Portugais

Portugais -

Pendjabi

Pendjabi -

roumain

roumain -

russe

russe -

Samoan

Samoan -

Gaélique écossais

Gaélique écossais -

serbe

serbe -

Anglais

Anglais -

Shona

Shona -

Sindhi

Sindhi -

Cinghalais

Cinghalais -

slovaque

slovaque -

slovène

slovène -

somali

somali -

Espagnol

Espagnol -

Soundanais

Soundanais -

Swahili

Swahili -

suédois

suédois -

Tagalog

Tagalog -

Tadjik

Tadjik -

Tamoul

Tamoul -

tatar

tatar -

Télougou

Télougou -

thaïlandais

thaïlandais -

turc

turc -

Turkmènes

Turkmènes -

ukrainien

ukrainien -

Ourdou

Ourdou -

Ouïghour

Ouïghour -

Ouzbek

Ouzbek -

vietnamien

vietnamien -

gallois

gallois -

Aide

Aide -

yiddish

yiddish -

Yorouba

Yorouba -

zoulou

zoulou

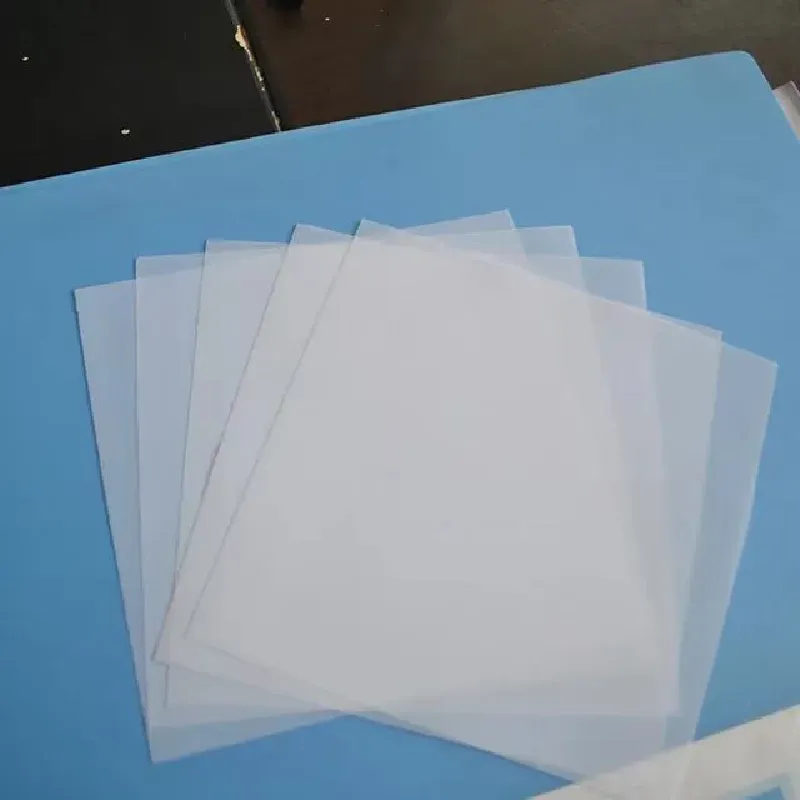

Precision Filtration Solutions for Industrial and Commercial Needs

In industries where purity, consistency, and efficiency are paramount, the right filtration material can make all the difference. Maille filtrante en nylon has emerged as a leader in filtration technology due to its durability, chemical resistance, and fine filtration capabilities. Whether you require Maille en nylon de 50 microns, 100 micron nylon mesh, or the ultra-fine 20 micron nylon mesh, nylon filter cloth mesh offers unparalleled performance across diverse applications.

From water treatment plants and chemical processing to food and beverage production, nylon filter mesh provides consistent particle retention while maintaining excellent flow rates. Its resilience under harsh conditions and ease of customization make it an ideal choice for manufacturers and engineers seeking reliability and precision.

Nylon Filter Mesh: Versatile Material for Diverse Filtration Applications

La polyvalence de maille filtrante en nylon lies in its ability to be tailored for a wide range of filtration requirements. Nylon’s natural resistance to abrasion, chemicals, and moisture allows it to maintain structural integrity in demanding environments.

This mesh is manufactured with precision weaving techniques that ensure uniform aperture sizes, essential for consistent filtration. Whether filtering solid particles from liquids or screening air impurities, nylon filter mesh performs efficiently with minimal pressure drop.

Its lightweight nature makes installation and maintenance easier compared to metal or fiberglass filters. Moreover, nylon filter mesh can be fabricated into different forms such as sheets, tubes, or custom-sized bags to meet specific industrial needs.

50 Micron Nylon Mesh: Balanced Filtration for Medium Particle Sizes

Le Maille en nylon de 50 microns represents a perfect balance between filtration fineness and flow rate. It is widely used in applications requiring the removal of particles approximately 0.05 millimeters in diameter, including sand, silt, and organic debris.

Industries such as wastewater treatment, paint manufacturing, and food processing rely heavily on 50 micron nylon mesh to protect equipment and ensure product quality. This mesh size also finds use in aquaculture and hydroponics, where water clarity is critical.

Fabricated with durable nylon threads, the 50 micron mesh withstands repetitive cleaning cycles and resists clogging better than many other synthetic filters. Additionally, it can be integrated with sealing and edge reinforcement processes to prevent fiber fraying and extend service life.

100 Micron Nylon Mesh: Effective Coarse Filtration with High Throughput

For applications where large particle filtration is required without compromising throughput, the 100 micron nylon mesh is an optimal choice. This mesh size efficiently filters debris, leaves, and other sizable contaminants in industrial water lines, irrigation systems, and manufacturing pipelines.

The robust weave of the 100 micron nylon mesh supports repeated mechanical cleaning and offers excellent tear resistance. It is commonly used as a pre-filter to prolong the life of finer filtration stages, providing cost-effective protection for pumps and valves.

The nylon fibers maintain flexibility even under varying temperatures and pressures, ensuring consistent performance in environments ranging from agricultural to chemical processing plants.

20 Micron Nylon Mesh: Precision Filtration for Ultra-Fine Particles

When the filtration of very fine particles is critical, 20 micron nylon mesh excels with its ability to capture contaminants as small as 0.02 millimeters. This ultra-fine mesh is essential in pharmaceutical manufacturing, laboratory filtration, cosmetics production, and high-purity chemical processes.

Despite its fine weave, the 20 micron nylon mesh remains durable and resistant to tearing and chemical degradation. Its smooth surface facilitates easy cleaning and reduces particle buildup, which helps maintain flow efficiency and prevents contamination.

This mesh can be formed into various configurations including filter bags, cartridges, and flat screens, making it adaptable for a range of sophisticated filtration systems requiring stringent quality standards.

Nylon Filter Cloth Mesh: Custom Fabrication and Enhanced Durability

Le maille en tissu filtrant en nylon is available in customizable sizes, thicknesses, and weave patterns to accommodate unique filtration demands. It can be processed into annular belts, bags, or pleated cartridges depending on the application.

Advanced edge treatments such as wrapping or glue brushing are applied to nylon filter cloth mesh to prevent wire stripping and extend its usable life. This is particularly important in continuous industrial operations where downtime is costly.

Additionally, nylon filter cloth mesh offers superior resistance to UV light, abrasion, and a broad range of chemicals. These properties make it a reliable choice for long-term filtration solutions in harsh environments.

With excellent tensile strength and dimensional stability, nylon filter cloth mesh can be used in combination with other filtration layers to optimize efficiency and meet regulatory requirements.

Nylon Filter Mesh FAQs

What industries benefit the most from nylon filter mesh?

Nylon filter mesh is widely used in water treatment, food and beverage, pharmaceuticals, chemical processing, agriculture, and aquaculture. Its chemical resistance, fine filtration capabilities, and durability make it ideal for applications requiring precise particle control and contamination prevention.

How do I choose between 20, 50, and 100 micron nylon mesh?

Choosing the correct micron size depends on the particle size you want to filter. Use 20 micron nylon mesh for ultra-fine filtration, such as pharmaceuticals or cosmetics. The 50 micron mesh balances fine filtration with flow rate for applications like wastewater and food processing. The 100 micron mesh is suitable for coarse filtration tasks like debris removal and pre-filtration.

Can nylon filter mesh withstand harsh chemical environments?

Yes, nylon filter mesh offers excellent resistance to many acids, alkalis, and solvents. However, it’s essential to confirm compatibility with specific chemicals used in your process. Nylon’s durability combined with proper fabrication and edge treatments ensures longevity in demanding environments.

Is nylon filter cloth mesh reusable and easy to clean?

Nylon filter cloth mesh is reusable and can be cleaned using water, mild detergents, or chemical cleaners depending on the application. Its smooth surface reduces particle adhesion, making maintenance straightforward and prolonging filter life.

What customization options are available for nylon filter mesh?

Nylon filter mesh can be customized in terms of mesh size, thickness, weave pattern, shape, and color. It can be processed into bags, belts, or framed screens. Advanced edge processing methods such as glue brushing or thermal sealing prevent fraying and increase durability, tailored to specific filtration system requirements.

-

Shipping Plastic Bags for Every NeedNouvellesJul.24,2025

-

Safety Netting: Your Shield in ConstructionNouvellesJul.24,2025

-

Plastic Mesh Netting for Everyday UseNouvellesJul.24,2025

-

Nylon Netting for Every UseNouvellesJul.24,2025

-

Mesh Breeder Box for Fish TanksNouvellesJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNouvellesJul.24,2025