-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Performance Steel Wire Mesh for Durable Filtration and Screening Applications

The Versatility of Steel Wire Screens Applications and Benefits

Steel wire screens have emerged as indispensable tools across various industries, offering a robust solution for filtration, separation, and protection. Known for their durability and versatility, these screens are engineered to meet the rigorous demands of numerous applications, ranging from construction and mining to agriculture and food processing. Understanding the composition, benefits, and applications of steel wire screens can help industries optimize their processes and improve operational efficiency.

Composition and Structure

Steel wire screens are constructed from high-quality steel wires that are woven, welded, or fabricated into various mesh configurations. The choice of steel—whether it be carbon steel, stainless steel, or galvanized steel—depends on the specific requirements of the application. For instance, stainless steel is preferred in environments where corrosion resistance is essential, whereas galvanized steel may be chosen for its cost-effectiveness and durability.

The mesh size and pattern are critical to the functionality of the screen; they can be tailored to meet precise filtration needs. Wire diameter, opening size, and the type of weave or weld can all be adjusted, making it possible to create screens that are fine enough to filter out small particles or coarse enough to allow larger materials to pass.

Benefits of Steel Wire Screens

One of the most significant advantages of steel wire screens is their strength and longevity. Unlike plastic alternatives, steel wire screens are resistant to wear and can withstand high-pressure conditions, making them ideal for heavy-duty applications. They endure extreme temperatures and are less prone to damage from environmental factors—maximizing their lifespan and minimizing replacement costs.

Another benefit is their versatility. Steel wire screens are used in various industries, including construction (for sand and gravel separation), agriculture (for grain cleaning), and even food processing (for producing juices and oils). Their adaptability allows manufacturers to customize screens for specific uses, enhancing productivity and efficiency.

Moreover, steel wire screens offer excellent flow rates

. Their open mesh design facilitates optimal air, liquid, and material flow, which is essential in processes like filtration, drainage, and screening. This efficiency can lead to lower operational costs and improved process throughput.steel wire screen

Applications Across Industries

1. Mining and Minerals Processing In the mining industry, steel wire screens are utilized for the separation of minerals and aggregates. They help in sorting and sizing materials during processing. The ruggedness of these screens ensures they can handle heavy loads and abrasive materials.

2. Construction In construction, steel wire screens are critical for sifting sand, gravel, or crushed stone. They are essential for producing concrete of different grades and ensuring that construction materials meet quality standards.

3. Agriculture Agricultural applications include using steel wire screens for sorting grains and seeds. These screens are essential for removing debris, ensuring the quality of the produce, and enhancing storage efficiency.

4. Food Processing In the food industry, steel wire screens are utilized in the filtration of liquids, such as juice extraction, oil filtering, and beer brewing. Their non-reactive nature in the case of stainless steel ensures food safety and compliance with health regulations.

5. Waste Management Steel wire screens play a vital role in waste management systems by aiding in the separation of materials and enhancing recycling processes. They are used to filter out contaminants, ensuring that processed materials achieve the required purity levels.

Conclusion

Steel wire screens are an integral part of numerous industries, offering durable, efficient, and customizable solutions for filtration, separation, and protection. Their strength, adaptability, and resistance to environmental factors make them a preferred choice over other materials. As industries continue to evolve and expand, the demand for such versatile tools is expected to grow, highlighting the importance of steel wire screens in modern applications. Understanding their benefits and applications can empower businesses to make informed decisions, enhancing productivity and ensuring operational success.

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

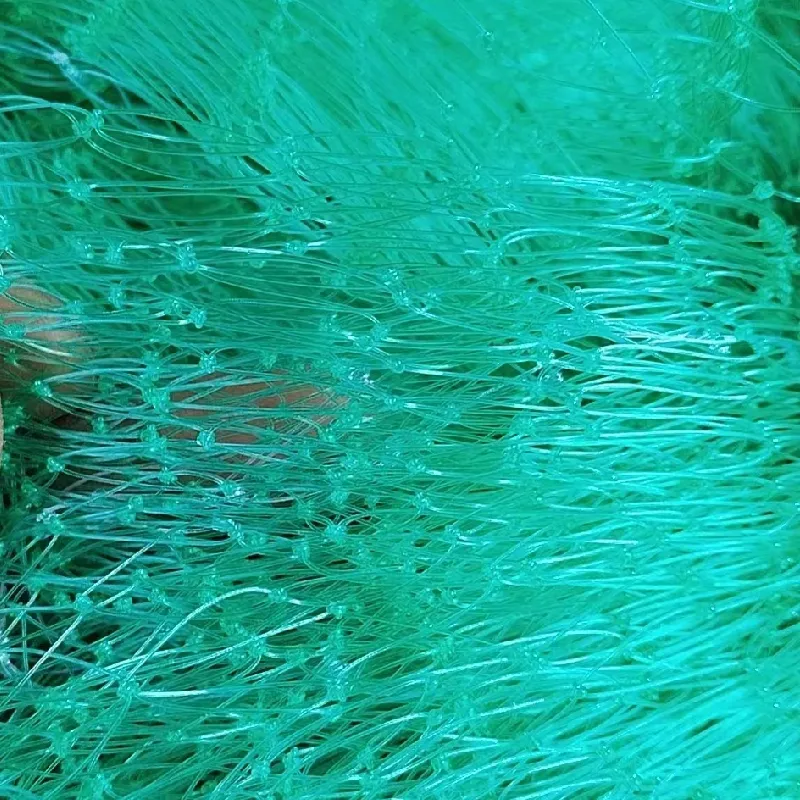

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025