-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Stainless Steel Mesh Filters for Efficient Liquid and Air Filtration Solutions

The Benefits of Using Stainless Steel Filter Mesh

In modern industrial applications, filtration plays a crucial role in maintaining the integrity and quality of various processes. Among the numerous filtration media available, stainless steel filter mesh stands out due to its versatility, durability, and effectiveness. This article explores the significance of stainless steel filter mesh, its applications, and the reasons why it is a preferred choice in many industries.

What is Stainless Steel Filter Mesh?

Stainless steel filter mesh is a woven material made from stainless steel wire. The wires are interlaced to form a mesh that allows certain particles, liquids, or gases to pass through while trapping others. The mesh size can be varied to accommodate different filtering requirements, making it adaptable for a range of applications.

Key Properties

1. Corrosion Resistance One of the most significant advantages of stainless steel is its inherent resistance to corrosion. This property ensures that stainless steel filter mesh can endure harsh environments, including those involving chemicals, moisture, and high temperatures. As a result, it maintains its structural integrity and performance over time.

2. Durability Stainless steel is known for its strength and durability. Unlike other materials, stainless steel mesh does not easily tear or degrade, even under intense operational conditions. This robustness extends the lifespan of the filter, reducing the need for frequent replacements and resulting in lower maintenance costs.

3. High Filtration Efficiency The precise arrangement of the wires in stainless steel filter mesh allows for effective filtration of small particles. The mesh can be engineered to achieve specific pore sizes, making it suitable for applications requiring fine filtration. This efficiency is essential in many sectors, including pharmaceuticals, food and beverage, and water treatment.

4. Temperature Resistance Stainless steel filter mesh can withstand high temperatures, making it ideal for applications that involve heat. This characteristic is crucial in industries such as petrochemical processing, where materials may be exposed to elevated temperatures.

5. Easy Cleaning The non-porous nature of stainless steel allows for easy cleaning and maintenance. Unlike porous filter materials, which can accumulate dirt and microorganisms, stainless steel mesh can be washed and reused, promoting sustainability.

filter mesh stainless steel

Applications of Stainless Steel Filter Mesh

Stainless steel filter mesh finds applications in various industries, owing to its unique properties

1. Food and Beverage Industry In this sector, maintaining hygiene and quality is paramount. Stainless steel filter mesh is employed in processes such as brewing, juice filtration, and dairy processing. Its ability to withstand regular cleaning cycles and corrosive cleaning agents makes it an ideal choice.

2. Water Treatment Water purification facilities utilize stainless steel filter mesh to remove contaminants and particulates from water sources. Its durability and effectiveness in filtration processes help ensure that potable water meets safety standards.

3. Chemical and Petrochemical Industries These industries often deal with corrosive substances and require materials that can withstand harsh conditions. Stainless steel filter mesh serves as excellent filters in refining and chemical processing, ensuring the smooth operation of equipment.

4. Pharmaceuticals In the pharmaceutical sector, precision and cleanliness are critical. Stainless steel filter mesh is used in various stages of drug manufacturing, such as separation and purification processes, to ensure that the final products are free from contaminants.

5. Oil and Gas Within the oil and gas industries, filtration is essential for both upstream and downstream processes. Stainless steel filter mesh is used to filter drilling fluids, protect pumps and other equipment, and ensure the quality of produced fluids.

Conclusion

Stainless steel filter mesh is an invaluable resource in many industrial applications due to its superior properties such as corrosion resistance, durability, and filtration efficiency. As industries continue to evolve and seek materials that offer performance and reliability, stainless steel filter mesh remains a top choice for engineers and manufacturers alike. Its adaptability to a vast range of processes not only enhances operational efficiency but also fosters sustainability through ease of cleaning and reusability. Whether in the food industry, pharmaceuticals, or environmental management, the role of stainless steel filter mesh is critical in ensuring quality and safety standards are met across diverse sectors. By investing in stainless steel filter mesh, businesses can ensure they are utilizing the best filtration solutions available, ultimately contributing to operational success and product integrity.

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

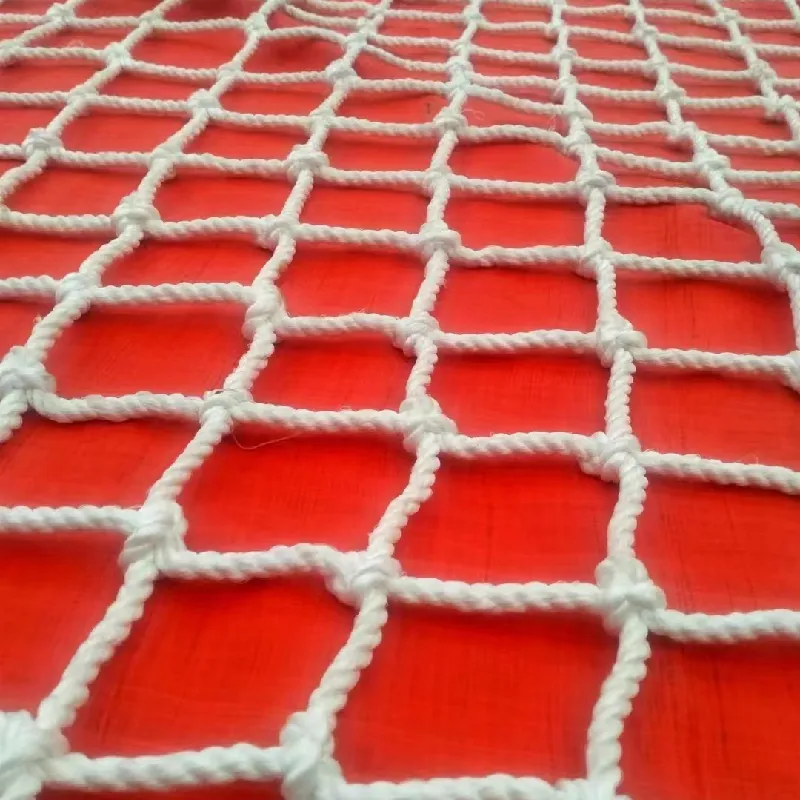

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025