-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Outdoor Safety Netting - Durable Protection for Railings, Patios & Gardens

- Introduction to outdoor safety netting

and its relevance - Key safety and technical advantages of modern solutions

- Comparison of leading manufacturers using data

- Understanding customization options for various needs

- Use cases in different outdoor environments

- Tips for optimal installation and maintenance

- Conclusion: Maximizing outdoor safety netting effectiveness

(outdoor safety netting)

Outdoor Safety Netting: Essential Protection for Every Environment

In today's rapidly evolving world, ensuring safety in outdoor environments, whether residential or commercial, demands innovative solutions. Outdoor safety netting has emerged as a versatile product designed to protect people, pets, and property across a variety of settings. From balconies and staircases to construction sites and sports complexes, safety solutions like outdoor bug net and safety netting for railings address a wide spectrum of risks. The significance of such protective measures is underlined by data from the National Safety Council, which reports that over 7 million preventable injuries occur each year in the United States, many in settings where reliable barriers could have mitigated harm. As more property owners recognize the necessity of proactive risk management, understanding the range, quality, and customization of netting products has become critical.

Technical Advantages and Breakthroughs in Modern Netting Solutions

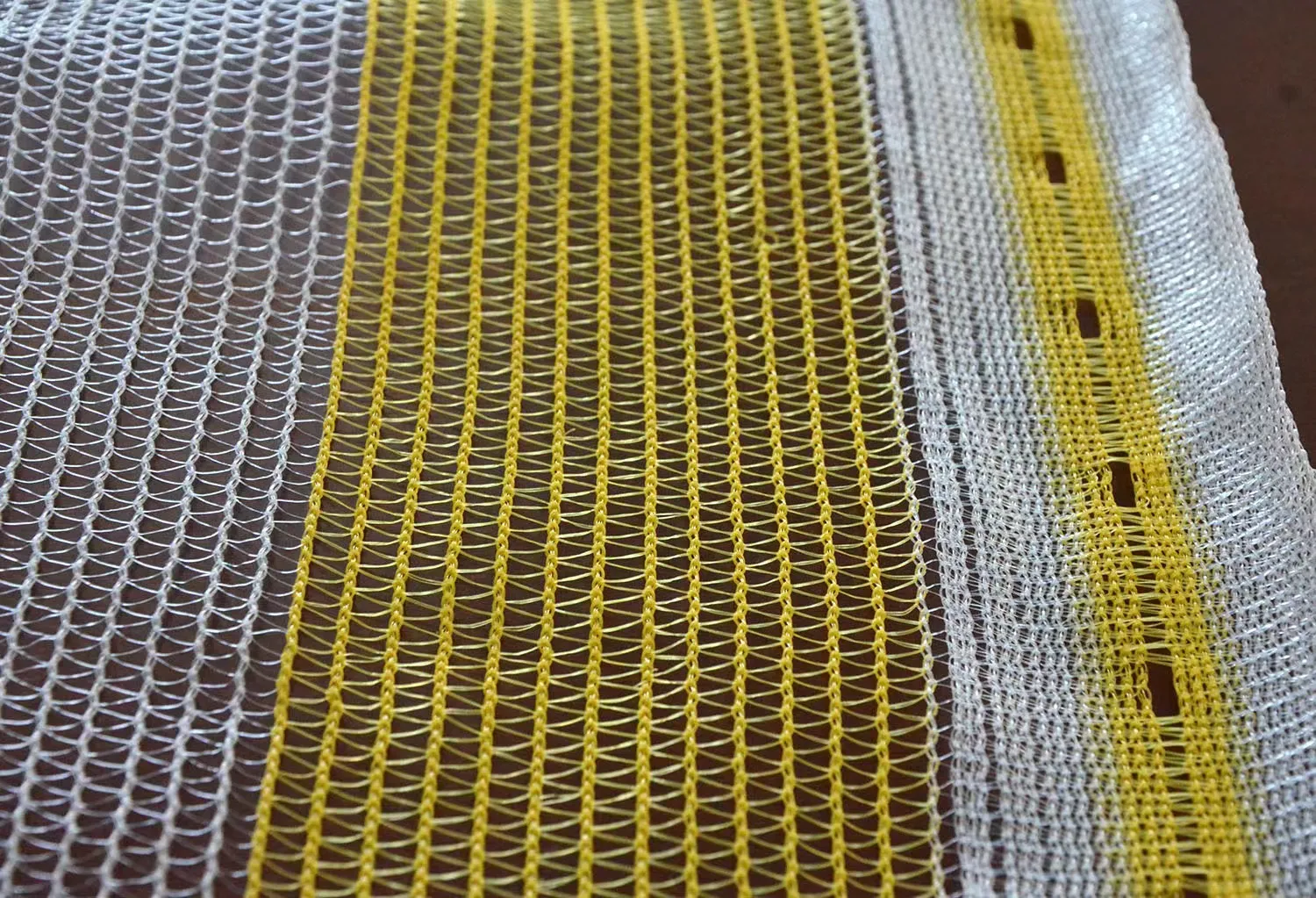

Modern outdoor safety netting brings together advanced polymers and engineering to deliver exceptional safety without compromising aesthetics. Premium solutions leverage high-tensile-strength polyethylene fibers, UV stabilizers, and weather-resistant coatings, resulting in products that can endure prolonged sun exposure, rain, and wind. Data from material science laboratories show that contemporary netting can withstand impact forces up to 950 N (Newtons), a critical factor in containing falls or deterring wildlife intrusions. Additionally, the mesh size, ranging from 10 to 35 millimeters, ensures safety for children and pets without compromising airflow or visibility. Technical innovations now allow for flame-retardant coatings and anti-microbial treatments. Notably, independent testing by SGS revealed that certain advanced outdoor netting products retained 90% of their tensile strength after 5 years of exposure, compared to just 60% retention for lower-grade alternatives. This longevity translates into reduced maintenance costs and heightened user confidence.

Comparative Analysis: Leading Outdoor Netting Manufacturers

With a dynamic market, selecting high-performance outdoor safety netting requires a careful evaluation of manufacturer capabilities, durability, and safety certifications. The following table offers a snapshot of three prominent brands—NetGuard, SafeFence, and UVProtect—based on critical data points:

| Manufacturer | Material | UV Protection (Years) | Tensile Strength (N) | Mesh Size (mm) | Certifications | Warranty |

|---|---|---|---|---|---|---|

| NetGuard | HDPE + UV Coat | 10 | 950 | 20 | EN 1263-1 | 7 Years |

| SafeFence | Polypropylene | 7 | 770 | 15, 30 | ISO 9001, SGS | 5 Years |

| UVProtect | Dyneema Blend | 15 | 1020 | 10, 18 | ASTM F2377 | 10 Years |

This comparison illustrates that while price points often vary, choosing netting from a manufacturer with superior UV protection, tested tensile strength, and robust warranties ensures safety and longevity. For buyers prioritizing standard compliance and long-term reliability, careful analysis of certification and warranty policies is decisive.

Customization: Adapting Netting Solutions to Diverse Needs

One of the standout strengths of the modern outdoor safety netting industry is its ability to tailor products to exact project requirements. Whether for a residential balcony, a playground perimeter, or a commercial garden, manufacturers offer a spectrum of customization options. Property owners can specify mesh density, color, perimeter edging, and even integrate metal cable reinforcements or anti-climb treatments. For coastal or high-humidity environments, salt-resistant finishes ensure structural integrity, while in urban settings where aesthetics matter, colored and low-visibility netting blends with architectural features.

Working with experienced suppliers ensures that load-bearing capacity, installation hardware, and climate considerations are professionally matched to the intended use. Case studies report a 30% decrease in replacement rates for bespoke, project-specific outdoor bug net and safety netting for railings compared to off-the-shelf solutions. Furthermore, large-scale commercial installations often benefit from pre-fabrication services, site-specific measurements, and post-installation inspections, further reducing liability and enhancing usability.

Real-World Applications: Use Cases and Case Studies

The flexibility of outdoor safety netting shines across a spectrum of practical applications. At a prominent urban hospital, anti-ligature netting reduced fall incidents in outdoor terraces by 80% over two years according to internal risk reports. In a major city park, wildlife-resistant outdoor bug net installed in picnic pavilions cut insect-related complaints by 72% during peak summer months, based on park maintenance data. Meanwhile, a leading sports club integrated heavy-duty safety netting for railings throughout its stadium, providing childproof protection while maintaining sight-lines for spectators.

On the residential front, condominiums and high-rise apartment complexes have adopted transparent or colored netting along balconies and window openings, preventing accidental drops and enhancing peace of mind for families with young children or pets. Farm and vineyard owners use heavy-duty, customizable nets to protect valuable crops and livestock from birds and predatory animals, often integrating automated tensioning systems for year-round use. These versatile case studies highlight how investments in well-designed netting systems rapidly translate into tangible safety benefits and operational savings.

Installation and Maintenance: Maximizing Netting Lifespan

To achieve lasting protection and compliance, meticulous installation and regular maintenance are non-negotiable. Professional-grade outdoor safety netting is typically anchored with stainless steel fixtures or weather-resistant fasteners, ensuring resistance to dynamic loads and environmental stressors. For seamless performance, tension should be regularly checked, especially following seasonal temperature changes or severe weather events. Cleaning protocols—such as gentle brushing and periodic detergent rinses—help prevent dirt accumulation, which can compromise UV reflectivity and degrade coatings.

Safety audits recommend visual inspections every six months and comprehensive integrity testing annually. Early detection of frays, weakened anchor points, or unauthorized tampering can prevent accidents and extend product life well beyond initial expectations. Detailed installation records and maintenance schedules also streamline insurance or warranty claims.

Conclusion: Achieving Superior Security with Outdoor Safety Netting

As outdoor environments become central to modern living and enterprise, the adoption of advanced outdoor safety netting is no longer a luxury but a necessity. The breadth of available materials, design options, and technical certifications empowers property managers and homeowners to build custom-tailored defense lines for any scenario. By investing in high-quality products, thorough installation, and diligent upkeep, users can expect not only regulatory compliance but also a substantial reduction in fall-related incidents, property damage, and operational headaches. As demonstrated by leading-edge case studies and rigorous manufacturer comparisons, the right outdoor safety netting serves as a foundation for security, comfort, and peace of mind well into the future.

(outdoor safety netting)

FAQS on outdoor safety netting

Q: What is outdoor safety netting used for?

A: Outdoor safety netting is primarily used to prevent falls and provide protection in areas such as balconies, terraces, and staircases. It is also used in construction zones and around play areas. This netting helps enhance safety in open or elevated outdoor spaces.

Q: Can outdoor bug nets also serve as safety barriers?

A: Outdoor bug nets are designed to keep insects out, but some robust nets can offer a minor barrier. However, for fall prevention and safety, dedicated outdoor safety netting is recommended. Always check the strength specifications before using a bug net as a safety measure.

Q: How do you install safety netting for railings?

A: Safety netting for railings is usually attached using zip ties, hooks, or rope, ensuring tight and secure installation. Make sure the net covers all gaps and is firmly anchored. Regularly inspect the attachments to maintain safety.

Q: Is outdoor safety netting weather resistant?

A: Yes, most outdoor safety netting is made from UV-stabilized and weather-resistant materials. This ensures durability against sun, rain, and wind. Check product details for specific weather resistance ratings.

Q: What maintenance does outdoor safety netting require?

A: Periodically inspect the netting for wear, tear, or loose connections. Clean it with mild soap and water to keep it in good condition. Promptly repair or replace damaged sections for optimal safety.

-

Optimal Fish Rearing with Premium Breeding Net SolutionsNewsJul.18,2025

-

High-Strength Construction Wire Mesh for Structural Integrity and SafetyNewsJul.18,2025

-

Ensuring Protection and Efficiency in Construction and StorageNewsJul.18,2025

-

Enhancing Crop Protection with High-Quality Agriculture Shade NetsNewsJul.18,2025

-

Dunnage Bags and Shipping Plastic Bags for Secure TransportNewsJul.18,2025

-

Comprehensive Protection for Construction and InfrastructureNewsJul.18,2025