-

Afirka

Afirka -

Albaniya

Albaniya -

Amharic

Amharic -

Larabci

Larabci -

Armenian

Armenian -

Azerbaijan

Azerbaijan -

Basque

Basque -

Belarushiyanci

Belarushiyanci -

Bengali

Bengali -

Bosniya

Bosniya -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Yaren mutanen Holland

Yaren mutanen Holland -

Turanci

Turanci -

Esperanto

Esperanto -

Estoniya

Estoniya -

Finnish

Finnish -

Faransanci

Faransanci -

Farisa

Farisa -

Galiciyan

Galiciyan -

Jojin

Jojin -

Jamusanci

Jamusanci -

Girkanci

Girkanci -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawayi

hawayi -

Ibrananci

Ibrananci -

A'a

A'a -

Miya

Miya -

Harshen Hungary

Harshen Hungary -

Icelandic

Icelandic -

igbo

igbo -

Indonesiya

Indonesiya -

Irish

Irish -

Italiyanci

Italiyanci -

Jafananci

Jafananci -

Yawanci

Yawanci -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Ruwanda

Ruwanda -

Yaren Koriya

Yaren Koriya -

Kurdish

Kurdish -

Kyrgyzstan

Kyrgyzstan -

TB

TB -

Latin

Latin -

Latvia

Latvia -

Lithuaniyanci

Lithuaniyanci -

Luxembourgish

Luxembourgish -

Makidoniya

Makidoniya -

Malagasy

Malagasy -

Malay

Malay -

Malayalam

Malayalam -

Maltase

Maltase -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Yaren mutanen Norway

Yaren mutanen Norway -

Yaren mutanen Norway

Yaren mutanen Norway -

Occitan

Occitan -

Pashto

Pashto -

Farisa

Farisa -

Yaren mutanen Poland

Yaren mutanen Poland -

Fotigal

Fotigal -

Punjabi

Punjabi -

Romanian

Romanian -

Rashanci

Rashanci -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Turanci

Turanci -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Sloveniya

Sloveniya -

Somaliya

Somaliya -

Mutanen Espanya

Mutanen Espanya -

Sundanci

Sundanci -

Harshen Swahili

Harshen Swahili -

Yaren mutanen Sweden

Yaren mutanen Sweden -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Baturke

Baturke -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Taimako

Taimako -

Yadish

Yadish -

Yarbawa

Yarbawa -

Zulu

Zulu

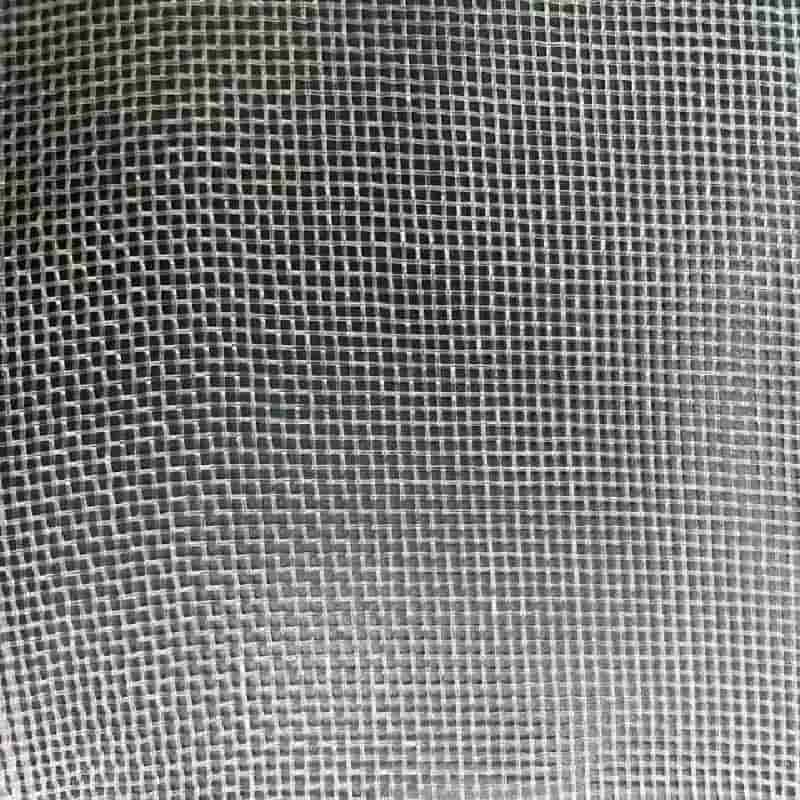

High-Performance Steel Mesh Solutions for Modern Industry

In today’s highly specialized industrial landscape, durable and adaptable materials are key to success. When it comes to building robust infrastructures, achieving precise filtration, or designing protective enclosures, metal mesh products have become indispensable. Among the most in-demand are expanded steel mesh, galvanised steel mesh, kuma woven stainless steel mesh—each offering unique structural benefits and corrosion resistance. Additionally, wire mesh manufacturers and suppliers are now more innovation-driven than ever, delivering advanced customization and industry-grade reliability to meet the growing global demand for stainless, perforated, and expanded mesh solutions.

From architectural applications to heavy-duty screening and reinforcement in construction, metal mesh is a fundamental building block in multiple sectors. As the complexity of projects increases, so too does the requirement for materials that deliver strength, flexibility, and resilience. Whether the goal is to create airflow without compromising security or to reinforce a concrete slab, the right mesh product can significantly improve the safety and longevity of the application.

Expanded Steel Mesh: Lightweight Strength with Industrial Versatility

Among the most versatile solutions in the metal mesh category is expanded steel mesh. It is created by slitting and stretching a solid sheet of steel into a mesh of diamond-shaped patterns without wasting material. This process not only produces a seamless structure but also enhances strength while keeping weight to a minimum. It is widely used in architectural features, protective grilles, walkways, fencing, and as reinforcement in cement and plaster.

Expanded steel mesh offers high rigidity under compression, yet can be easily fabricated into complex shapes, allowing designers and engineers flexibility in application. Its open pattern supports excellent airflow, visibility, and drainage—qualities that are especially valuable in industries like mining, transportation, and construction. In addition, the mesh serves as an effective anti-slip surface in floor grates and stair treads, improving safety without requiring additional coatings or treatments.

Its adaptability is also appreciated in artistic and architectural environments where both aesthetic appeal and structural performance are desired. Façade designers use expanded steel mesh to create dynamic visual textures while maintaining building ventilation and sunlight penetration.

Wire Mesh Manufacturers: Delivering Quality through Precision Engineering

The success of any mesh application hinges not only on the raw material but also on the precision with which it is manufactured. Top-tier wire mesh manufacturers have evolved into full-service solution providers, offering cutting-edge fabrication, custom specifications, and international-grade certifications. They work closely with industries such as oil and gas, aerospace, agriculture, chemical processing, and defense to ensure that each mesh product adheres to rigorous performance standards.

Modern manufacturers rely on digital CAD systems and automated weaving or welding technologies to guarantee consistency across large volumes. These technologies allow for exacting control over wire diameter, aperture size, tensile strength, and mesh geometry. Clients can select from a broad spectrum of materials including mild steel, aluminum, copper, brass, and stainless steel to meet specific conductivity, thermal, or corrosion-resistance needs.

Beyond production, top wire mesh suppliers provide tailored surface treatments such as galvanization, powder coating, or passivation. These finishing processes improve longevity and ensure the mesh performs optimally in the intended environment, whether it’s a marine dock, a food-grade facility, or a high-heat production line.

Perforated Stainless Steel Mesh: Designed for Strength and Flow Control

Engineered for applications where controlled permeability is essential, perforated stainless steel mesh is a top-tier solution across multiple industries. Its structure comprises a sheet of stainless steel with uniform holes punched into it, allowing for airflow, light diffusion, sound attenuation, or fluid passage, depending on the application. Commonly used in HVAC systems, speaker grilles, lighting covers, filtration devices, and even medical equipment, this mesh type combines strength with precision control.

What sets perforated stainless steel mesh apart is its ability to handle intense physical and chemical stress. Whether exposed to high temperatures, corrosive substances, or mechanical abrasion, stainless steel offers long-term reliability. The size, shape, and distribution of the perforations can be customized to achieve specific flow dynamics, making it an essential material in fluid engineering and industrial processing.

Its aesthetic appeal also makes it a favorite in architectural design. From sunscreens and balustrades to decorative walls and ceiling panels, perforated stainless steel meshes bring a sleek, modern look while serving important structural functions. The surface can also be treated to reflect light or resist fingerprints, extending its utility to commercial interiors and public spaces.

Galvanised Steel Mesh: Corrosion Resistance for Harsh Environments

When strength must be paired with protection from the elements, galvanised steel mesh provides a reliable solution. This mesh is coated with a layer of zinc, which acts as a barrier to moisture, chemicals, and atmospheric oxidation. It is a mainstay in construction, agriculture, infrastructure development, and transportation, especially in outdoor or marine applications where rust is a critical concern.

Galvanised mesh offers a durable and cost-effective option for fencing, cages, aviaries, retaining walls, and concrete reinforcements. Its long-lasting surface finish requires minimal maintenance and ensures high performance even after prolonged exposure to rain, humidity, or industrial pollutants. The galvanization process also enhances resistance to mechanical wear, adding to its overall lifespan.

For contractors and developers, galvanised mesh is easy to work with on-site. It cuts and bends without compromising the zinc coating, maintaining protection throughout the finished structure. When paired with concrete, it minimizes the risk of corrosion from within and helps preserve the structural integrity of buildings, bridges, and highways.

Woven Stainless Steel Mesh: Precision Filtration and Industrial Performance

Woven stainless steel mesh is the material of choice for industries requiring high-precision filtration, sieving, and separation. Created by interlacing stainless steel wires into a uniform grid, this mesh type allows for tight control over particle size exclusion, making it ideal for water purification systems, pharmaceuticals, food processing, petrochemicals, and laboratory applications.

The weave pattern—whether plain, twill, or Dutch—can be selected to meet specific needs for tensile strength, permeability, and flexibility. With micron-level accuracy, woven stainless steel mesh is particularly useful in gas filtration, liquid-solid separation, and fine particle sieving. Its thermal stability and resistance to acids, alkalis, and solvents make it a versatile performer in chemically aggressive environments.

In addition to technical functions, woven mesh is also employed in interior design, art installations, and even protective apparel. The uniform surface and metallic sheen provide visual appeal, while the inherent strength of the mesh ensures durability in creative applications.

Expanded Steel Mesh FAQs

What makes expanded steel mesh a preferred choice over welded mesh?

Expanded steel mesh is formed from a single sheet of steel, which eliminates weak points like welded joints. This results in a stronger, more durable structure with a higher strength-to-weight ratio. It also offers better load distribution and greater flexibility for shaping or bending without compromising the mesh’s integrity.

Why should I source from reputable wire mesh manufacturers?

Working with experienced wire mesh manufacturers ensures product quality, consistency, and compliance with industry standards. These manufacturers offer expert consultation, customization, and quality assurance processes that guarantee your mesh products meet the exact specifications needed for your project, minimizing risk and reducing operational downtime.

How does perforated stainless steel mesh differ from woven mesh?

Perforated stainless steel mesh is created by punching holes into a solid sheet, whereas woven mesh is made by weaving wires together. Perforated mesh offers more rigidity and is suitable for structural or aesthetic applications, while woven mesh provides better flexibility and control over filtration accuracy. Each serves different industrial needs based on performance requirements.

Can galvanised steel mesh be used in coastal environments?

Yes, galvanised steel mesh is specifically designed to resist corrosion in high-humidity and salt-laden air. The zinc coating forms a protective layer that delays rusting, making it ideal for marine infrastructure, coastal fencing, or storage units exposed to oceanic climates.

Is woven stainless steel mesh reusable?

Absolutely. Woven stainless steel mesh is not only durable but also washable and reusable in most settings. Its resistance to corrosion and structural deformation allows it to withstand multiple cycles of use, especially in industrial processes that demand frequent cleaning or exposure to high temperatures.

-

The Sunshade Net Can Block Ultraviolet RaysLabaraiAug.11,2025

-

Main Application and Technology of Nylon ScreenLabaraiAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceLabaraiAug.11,2025

-

Explore the Sunshade NetLabaraiAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentLabaraiAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureLabaraiAug.11,2025