-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

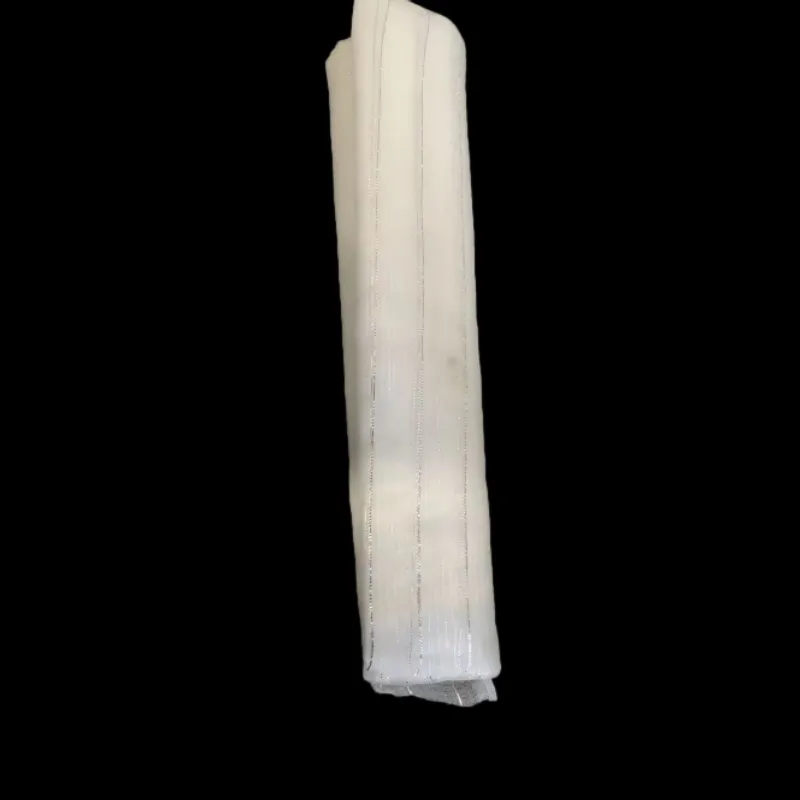

filter stainless

The Importance of Filter Stainless Steel in Modern Applications

In today’s industrial landscape, the demand for high-quality filtration systems has never been greater. As businesses strive to enhance efficiency and ensure the purity of their products, materials used in constructing filtration devices must meet stringent standards. One material that has gained prominence is filter stainless steel, renowned for its durability, corrosion resistance, and overall effectiveness in a variety of applications.

Filter stainless steel, often classified into various grades, is characterized by its unique properties, making it a preferred choice in numerous industries. The most commonly used grades include stainless steel 304 and 316. The former is highly versatile and cost-effective, while the latter provides enhanced corrosion resistance due to its molybdenum content, making it suitable for marine environments and chemical processing. These properties make filter stainless steel an ideal option for constructing filters that maintain both integrity and functionality over time.

One of the significant advantages of filter stainless steel is its resistance to corrosion

. In many applications, such as water treatment, pharmaceuticals, and food processing, exposure to corrosive substances and extreme conditions is inevitable. Stainless steel filters can withstand these harsh environments without deteriorating, ensuring that they remain effective and safe for extended periods. This characteristic not only extends the lifespan of filtering equipment but also reduces maintenance costs for businesses.filter stainless

Moreover, filter stainless steel can endure high temperatures, making it suitable for applications that involve heat. In industries such as oil and gas, where the filtration of high-temperature fluids is commonplace, using stainless steel ensures that the filters maintain their structural integrity. Additionally, stainless steel is easy to clean and maintain, which is crucial for industries that require hygienic processes, such as food and beverage production.

The versatility of filter stainless steel is also reflected in its various applications. In water purification systems, for example, these filters are essential for removing impurities and contaminants, ensuring that the water is safe for consumption. In the pharmaceutical industry, stainless steel filters help maintain sterile environments, crucial for producing drugs and vaccines. Furthermore, in the automotive sector, stainless steel filters are employed to protect machinery and improve overall efficiency.

In terms of sustainability, filter stainless steel stands out as an environmentally friendly option. It is recyclable, and its durability leads to less waste generation over time. As more companies adopt sustainable practices, the use of materials like filter stainless steel aligns with these goals, promoting responsible resource management.

In conclusion, filter stainless steel is an indispensable material in modern filtration systems across diverse industries. Its unique properties—such as corrosion resistance, high-temperature endurance, and ease of maintenance—make it an ideal choice for ensuring the integrity and effectiveness of filtration processes. As industries continue to evolve and seek sustainable solutions, the role of filter stainless steel will undoubtedly remain significant, providing businesses with the reliability and performance they require in today’s competitive market.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025