-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

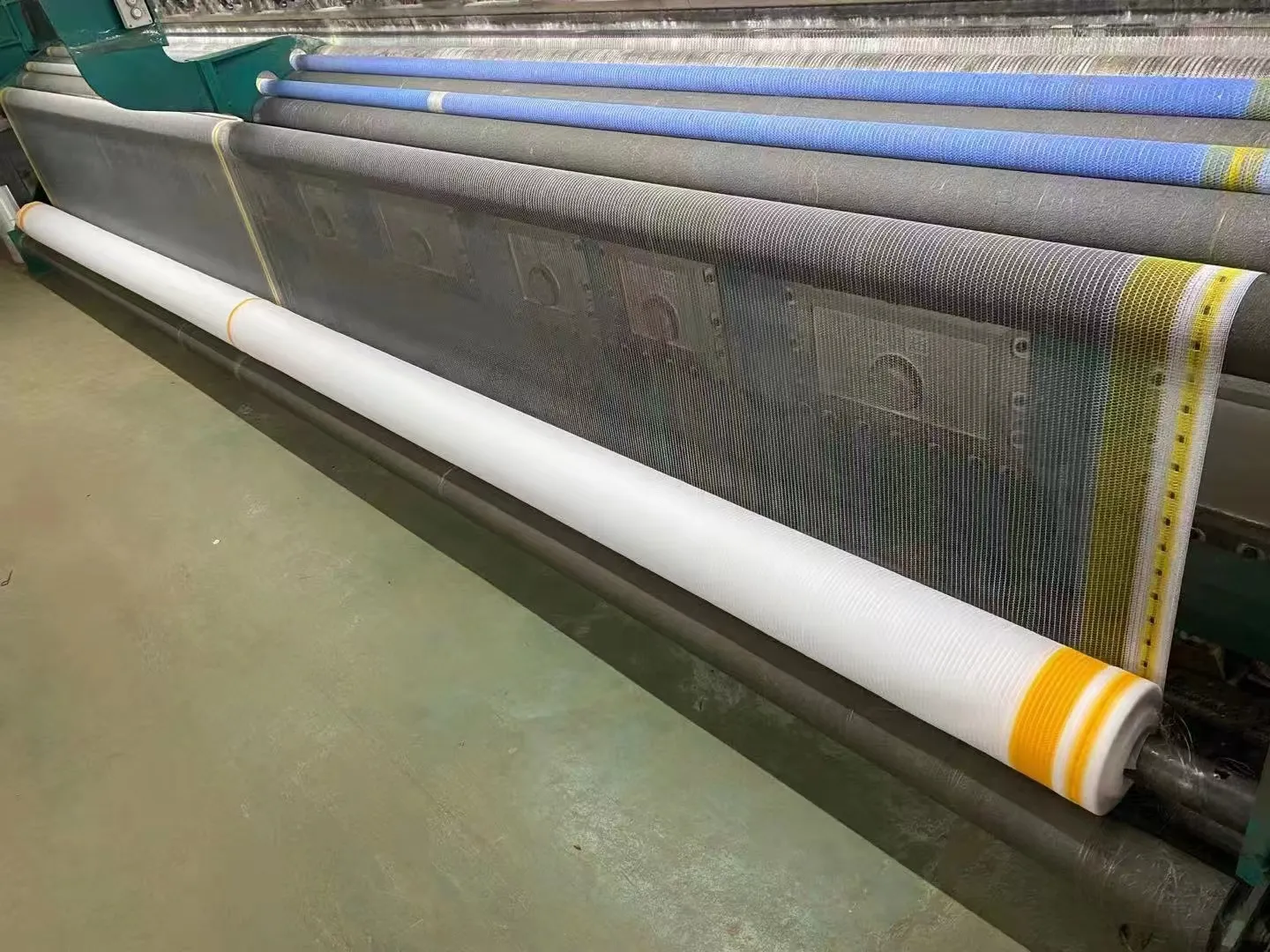

Durable Hard Plastic Netting & Rigid Mesh Solutions

- Introduction to Hard Plastic Netting and Its Market Impact

- Technical Advantages of Rigid Plastic Mesh Solutions

- Performance Comparison of Leading Manufacturers

- Custom Fabrication Capabilities and Design Options

- Industrial Applications Across Major Sectors

- Material Selection Guide for Specific Use Cases

- Implementing Hard Plastic Mesh in Modern Engineering

(hard plastic netting)

Introduction to Hard Plastic Netting and Its Market Impact

The global hard plastic netting

market reached $2.3 billion in 2023 with projected CAGR of 6.8% through 2030, driven by industrial automation demands. Unlike traditional metal wire mesh or textile netting, engineered polymers like HDPE, PVC, and polypropylene provide corrosion resistance while maintaining structural rigidity under stress. Recent breakthroughs in polymer science enable tensile strengths exceeding 45 MPa while reducing material density by 70% compared to steel alternatives.

Unveiling the Technical Superiority of Hard Plastic Netting

UV-stabilized polymers extend product lifespan beyond 15 years in outdoor installations. Material science innovations achieve temperature resistance from -40°C to 120°C, outperforming conventional materials. Thermoplastic formulations provide chemical resistance against acids, alkalis, and solvents while preventing microbial growth in humid conditions. Vibration dampening properties reduce maintenance frequency across equipment protection applications.

Performance Comparison of Leading Rigid Plastic Mesh Producers

| Manufacturer | Material Options | Mesh Range (mm) | Max Load Capacity | Certifications |

|---|---|---|---|---|

| PolymerGrid Inc | HDPE, PVC, PP | 2-100 | 850 kg/m² | ISO 9001, FDA |

| TechniWeave Corp | Nylon, PET, TPO | 1-50 | 1200 kg/m² | UL, REACH |

| DuraNet Solutions | HDPE, PVC | 5-150 | 650 kg/m² | ISO 14001 |

Custom Fabrication Capabilities for Specialized Requirements

Industrial users specify aperture geometries including diamond, square, or hexagonal patterns with tolerance control within ±0.15mm. Manufacturers offer thickness customization from 1mm to 15mm sheets, with edge binding options preventing unraveling. Multi-layer configurations combine impact resistance with filtration capabilities. Color compounding incorporates UV-inhibiting pigments without compromising structural integrity.

Industrial Applications Across Critical Sectors

Material handling systems integrate wear-resistant plastic mesh in conveyor components, reducing friction-related energy costs by 18% versus metal alternatives. Construction safety installations incorporate 300kN-rated debris netting meeting EN 1263 standards. Agricultural applications include predator-proof poultry netting with 7-year UV warranties. Unique applications span automotive radiator grilles to aquaculture tank dividers.

Material Selection Criteria for Optimal Performance

High-density polyethylene excels in chemical containment while polypropylene provides superior fatigue resistance for vibration-prone environments. PVC formulations maintain flexibility at sub-zero temperatures for cold storage partitions. Nylon composites offer maximum impact strength exceeding 15 J/m in protection barriers. Material selection matrices must consider load duration patterns and chemical exposure profiles.

Implementing Hard Plastic Mesh in Modern Engineering

Installation techniques for rigid plastic netting reduce labor requirements by 40% compared to metal alternatives, with integrated connection points accommodating tension loads exceeding 25kN. Testing confirms material performance retention after 200,000 stress cycles in industrial screening applications. Project specifications increasingly require 30% recycled polymer content without compromising structural integrity.

(hard plastic netting)

FAQS on hard plastic netting

以下是根据核心关键词“hard plastic netting”及其相关词(如“hard plastic rigid plastic mesh”和“hard plastic mesh”)创建的5组FAQs的HTML富文本输出。每组问题使用H3标签包裹,问题以“Q:”开头,回答以“A:”开头,问题和回答均控制在三句话内。输出采用HTML结构,确保富文本格式兼容。Q: What is hard plastic netting used for?

A: Hard plastic netting is applied in construction for reinforcement and industrial barriers. It provides high strength and durability in outdoor settings. Common uses include garden fencing and packaging support systems.

Q: How does hard plastic rigid plastic mesh differ from soft plastic nets?

A: Hard plastic rigid plastic mesh offers superior rigidity and impact resistance compared to soft nets. It maintains shape under pressure for structural applications. Advantages include better longevity in harsh environments.

Q: What materials are used in hard plastic mesh?

A: Hard plastic mesh is typically made from polymers like polyethylene or polypropylene. These materials ensure high tensile strength and weather resistance. Manufacturing involves injection molding for durable, cost-effective solutions.

Q: Is hard plastic netting recyclable?

A: Yes, many hard plastic netting products are recyclable due to thermoplastic composition. Recycling reduces waste and supports eco-friendly disposal. Check local facilities to ensure proper processing for rigid plastic items.

Q: Can hard plastic mesh be customized for specific projects?

A: Yes, customization options include size adjustments and hole patterns for unique applications. Tailored solutions cover areas like filtration systems and safety barriers. Suppliers often provide this flexibility based on industrial needs.

`)中以实现富文本效果。 - 每组FAQ控制在三句话内:问题本身为一句(如H3内文本),回答不超过三句(每句以逗号或分号分隔)。 - 输出兼容现代浏览器和富文本编辑器,可直接嵌入网页或CMS。

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025