-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Stainless Steel Welded Wire for Various Applications and Projects

The Versatility of Stainless Steel Welded Wire

Stainless steel welded wire is a remarkable material that has gained widespread popularity across various industries due to its exceptional properties and versatility. This article explores the characteristics, advantages, applications, and maintenance of stainless steel welded wire, making it a crucial choice for numerous applications.

Characteristics of Stainless Steel Welded Wire

Stainless steel welded wire is manufactured by welding together stainless steel wire strands at designated intervals, creating a robust mesh. Typically composed of chromium and nickel, this material boasts excellent corrosion resistance, strength, and durability. The welding process enhances the overall integrity of the wire mesh, ensuring it maintains its shape and functionality even under substantial stress.

Available in several grades, including 304 and 316, stainless steel welded wire caters to diverse environments and requirements. Grade 304 is commonly used for its good corrosion resistance and is ideal for indoor applications. In contrast, Grade 316 offers enhanced protection against corrosion from saltwater and chemicals, making it suitable for marine environments and industrial applications.

Advantages of Stainless Steel Welded Wire

One of the most significant advantages of stainless steel welded wire is its resistance to rust and corrosion. This makes it an excellent choice for outdoor use and in environments exposed to moisture and chemicals. Unlike other materials, stainless steel will not deteriorate over time, ensuring durability and longevity.

Another beneficial property is its strength-to-weight ratio. Stainless steel welded wire is incredibly strong yet lightweight, allowing for easy handling and installation. Additionally, its ability to withstand high temperatures makes it ideal for environments that experience thermal fluctuations.

The aesthetic appeal of stainless steel is another factor contributing to its popularity. With a sleek, shiny finish, stainless steel welded wire is not only functional but also visually appealing. This feature has led to its use in architectural applications, where aesthetics are just as important as functionality.

Applications of Stainless Steel Welded Wire

Stainless steel welded wire is used in various industries, thanks to its versatility

. Common applications includestainless steel welded wire

1. Construction Used as reinforcement in concrete and masonry to improve structural integrity.

2. Fencing Ideal for livestock pens, garden fences, and security barriers due to its strength and resistance to weather conditions.

3. Industrial Use Employed in the production of equipment such as shelves, baskets, and enclosures where hygiene and safety are paramount.

4. Marine Applications Used in boat building and marine structures due to its excellent corrosion resistance in saltwater environments.

5. Gardening and Agriculture Utilized for trellises, plant supports, and protective barriers to keep animals away from crops.

6. Food Industry Commonly used in food processing equipment, ensuring cleanliness and compliance with hygiene standards.

Maintenance and Care

Despite its durability, some basic maintenance can help extend the life of stainless steel welded wire. Regular cleaning with mild soap and water is recommended to remove dirt, grime, and corrosive substances. In environments with high exposure to salt or chemicals, more frequent cleaning may be necessary.

For best results, avoid using harsh chemicals or abrasive materials that could scratch the surface of the wire. In cases where rust appears, it can typically be removed with a non-abrasive cleaner or a solution specifically designed for stainless steel.

Conclusion

Stainless steel welded wire is a versatile and reliable material suitable for various applications. Its impressive properties, including corrosion resistance, strength, and aesthetic appeal, make it an exceptional choice for industries ranging from construction to agriculture. Proper maintenance ensures that stainless steel welded wire continues to perform at its best, providing durability and reliability for years to come. Whether used in fencing, reinforcement, or industrial solutions, stainless steel welded wire stands out as an essential material in modern design and construction.

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

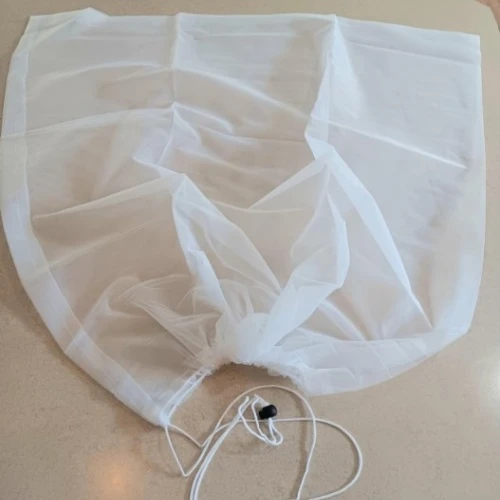

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025