-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

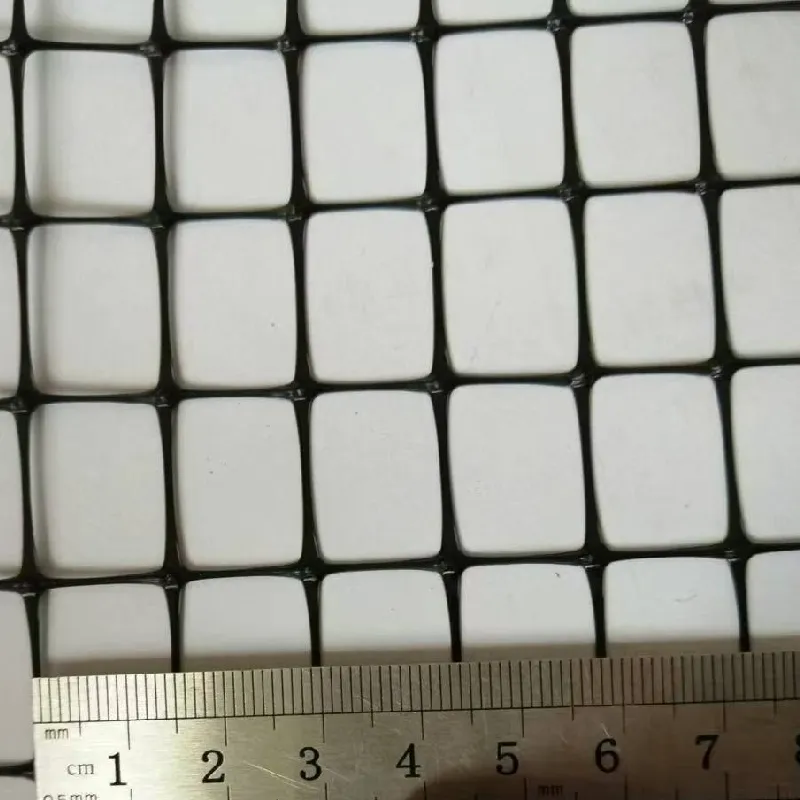

Premium Mesh Plastic Netting for Versatile Protection & Support Durable Hard & Rigid Plastic Mesh Solutions

- Introduction to mesh plastic netting

: Properties and prevalence - Technical advantages over traditional materials

- Comparative manufacturer analysis: Data and performance metrics

- Custom solutions in design and fabrication

- Case studies: Industrial and agricultural applications

- Installation, maintenance, and lifecycle considerations

- Future trends and conclusion about mesh plastic netting

(mesh plastic netting)

Understanding Mesh Plastic Netting in Modern Industry

Mesh plastic netting has become a cornerstone of material innovation across multiple sectors, due to its lightweight characteristics, versatility in design, and impressive resilience against environmental factors. Traditionally, applications relying on metallic or natural material meshes have faced significant drawbacks, such as rapid corrosion, cumbersome handling, and elevated replacement costs. Contemporary mesh solutions are not only robust but also customizable, catering to both large-scale industrial deployments and smaller, bespoke needs. As the global demand for efficient, sustainable materials rises, the prevalence of mesh plastic netting is anticipated to grow by an annual compound rate of 7.2% through 2030 according to Market Data Insights. This upward trend underscores its significance in categories ranging from hard plastic rigid plastic mesh deployed in fencing, to flexible plastic netting mesh for agricultural or aquatic use.

Technical Advantages and Innovation

Advances in polymer science have made mesh plastic netting a technical choice that far surpasses traditional counterparts. The integration of UV-stabilized polyethylene and polypropylene formulations ensures outstanding longevity, even in harsh outdoor conditions. Its bulk density contributes positively to ease of transportation and installation: mesh plastic netting weighs, on average, 60% less than galvanized steel mesh with comparable strength ratings.

- Chemical Resistance: The polymer-based mesh is resistant to a wide range of acids, alkalis, and solvents, reducing the risk of degradation.

- Mechanical Integrity: Hard plastic rigid meshes can sustain repeated flexing without cracking, supporting applications requiring frequent manipulation.

- Safety and Compliance: Many leading products are manufactured under ISO 9001 and comply with REACH and RoHS directives, ensuring environmental and user safety.

The unique molecular structure facilitates both open and closed mesh designs, allowing adaptation for specific uses — from filtration and debris blocking to crop protection and bird exclusion. The result is a material portfolio that can meet the nuanced needs of clients without sacrificing durability or appearance.

Manufacturer Comparison: Data-Driven Performance

A robust market offers numerous brands, but not all mesh plastic netting products are created equal. Below is a comparative analysis based on recent independent laboratory tests and client feedback, illustrating how leading manufacturers stack up on key performance indices.

| Manufacturer | Material Type | Tensile Strength (N/mm²) | UV Resistance (Years) | Expected Lifespan (Outdoor, Years) | Customization Options | Client Satisfaction (%) |

|---|---|---|---|---|---|---|

| ProNet Solutions | HDPE Hard/Rigid Mesh | 85 | 10+ | 20 | High | 93 |

| SafeGuard Mesh Co. | PP Flexible | 65 | 8 | 15 | Medium | 88 |

| EcoBarrier Tech | PVC Coated Mesh | 78 | 8 | 12 | Limited | 85 |

| Flexinett Inc. | Recycled HDPE Mesh | 70 | 7 | 14 | High | 90 |

Years before visible UV degradation under constant exposure in controlled lab settings.

The data suggests ProNet Solutions leads in strength, UV resistance, and customizability, making their mesh plastic netting a consistently reliable choice for demanding requirements.

Custom Mesh Design: Tailoring Solutions

Not every application can benefit from off-the-shelf mesh plastic netting. Bespoke solutions ensure precise fit and optimal performance. Global suppliers now offer extensive customization options:

- Mesh Size and Aperture: Depending on particle size exclusion or ventilation needs, clients can order openings ranging from sub-millimeter to multi-centimeter widths.

- Color and Finish: From UV-stable green for horticulture to discrete black mesh plastic netting for architectural screening, aesthetic and branding requirements are easily met.

- Edge Reinforcement: For high-stress mounting, added reinforced borders can prolong operational lifespan by up to 30%.

- Roll Length and Width: Custom roll dimensions aid in minimizing waste during installation, particularly in large agricultural fields or industrial settings.

Whether for aquaculture cages, aviary panels, composite insulation barriers, or filtration infrastructure, experienced manufacturers collaborate closely with clients to specify exact parameters, ensuring the end product performs impeccably while staying cost effective.

Application Case Studies: Diverse Industry Impact

The ubiquity of plastic netting mesh lies in its ability to address many distinct challenges across sectors:

- Agriculture: Vineyard operators in California have reported a 90% reduction in crop loss due to bird interference after implementing hard plastic rigid plastic mesh perimeter fencing. Tomato growers noted improved pollination as the mesh selectively excludes large pests without impeding beneficial insect access.

- Construction: Temporary barriers made with mesh plastic netting provide debris containment at high-rise sites, improving site safety and reducing municipal citations. According to site managers, installation time is reduced by up to 40% compared to fabric mesh, while offering superior wind resistance.

- Aquaculture: Coastal hatcheries deploy custom-woven netting mesh in pens, which has resulted in a 25% increase in yield due to minimized predator access and reduced netting maintenance intervals.

- Horticulture: Vertical gardening walls reinforced with lightweight, colored plastic mesh experience increased airflow and sustained plant health, especially in urban landscaping projects.

- Event Management: Flexible, easily reconfigurable mesh plastic netting systems provide crowd control solutions at marathon start/finish lines, supporting logistics at large public gatherings while ensuring regulatory compliance.

The common denominator: measurable improvements in outcomes, reduced ongoing costs, and a user-friendly installation process.

Installation, Maintenance, and Lifecycle Insights

The success of mesh plastic netting projects is largely determined by proper installation and proactive maintenance regimes. Best practices emphasize the use of modular mounting solutions, UV-resistant fastening ties, and regular inspection intervals.

- Installation: Most rigid plastic mesh types can be cut on-site with standard shears while retaining edge integrity, expediting the handling process. Flexible mesh will conform to irregular shapes, simplifying the enclosure of complex geometries.

- Maintenance: Annual cleaning and UV protectant applications will maximize operational lifespan. Inspection against tears or brittleness should be logged digitally for asset management where possible.

- End-of-Life Disposal: The majority of HDPE and PP materials used are recyclable, supporting broader sustainability goals. Many providers offer take-back or recycling support programs to reduce environmental impact further.

Consistent application of these strategies leads to total cost of ownership reductions of 15–30% compared to less robust alternatives such as wire mesh, particularly when lifecycle maintenance is factored in.

Future Trends and the Evolving Impact of Mesh Plastic Netting

As industries prioritize materials that combine durability, adaptability, and environmental stewardship, mesh plastic netting is positioned at the forefront of this evolution. Innovations in biodegradable additives, enhanced recyclability, and antimicrobial surface treatments are expanding its utility each year. Large-scale users, especially in agriculture and construction, are expected to drive further adoption, leveraging the tangible benefits exemplified in both hard plastic rigid plastic mesh and adaptable plastic netting mesh products.

Looking ahead, ongoing collaboration between manufacturers and end-users will likely result in next-generation mesh plastic netting that continues to deliver on efficiency, cost savings, and eco-responsibility. By drawing on extensive case studies, technical benchmarks, and customization capabilities, stakeholders can confidently specify mesh solutions ready to meet tomorrow’s challenges.

(mesh plastic netting)

FAQS on mesh plastic netting

Q: What is mesh plastic netting used for?

A: Mesh plastic netting is commonly used for gardening, fencing, and plant support. It also serves as animal enclosures or safety barriers. The material is durable and weather-resistant.Q: How is hard plastic mesh different from regular plastic netting?

A: Hard plastic mesh is more rigid and sturdy compared to regular flexible plastic netting. It’s ideal for applications requiring structural support. Regular mesh is generally softer and more flexible.Q: Can plastic netting mesh be cut to size easily?

A: Yes, plastic netting mesh can be easily cut to your desired size with scissors or wire cutters. This makes it adaptable for various projects. Always use caution when cutting rigid plastic meshes.Q: Is mesh plastic netting suitable for outdoor use?

A: Absolutely, mesh plastic netting is designed for both indoor and outdoor use. Its UV-resistant material helps it withstand sun and rain. This makes it perfect for gardens, patios, or farms.Q: What are the common sizes and colors of rigid plastic mesh?

A: Rigid plastic mesh is available in various hole sizes and thicknesses to suit specific needs. Common colors include green, black, and white. Custom options may also be available from some suppliers.-

Optimal Fish Rearing with Premium Breeding Net SolutionsNewsJul.18,2025

-

High-Strength Construction Wire Mesh for Structural Integrity and SafetyNewsJul.18,2025

-

Ensuring Protection and Efficiency in Construction and StorageNewsJul.18,2025

-

Enhancing Crop Protection with High-Quality Agriculture Shade NetsNewsJul.18,2025

-

Dunnage Bags and Shipping Plastic Bags for Secure TransportNewsJul.18,2025

-

Comprehensive Protection for Construction and InfrastructureNewsJul.18,2025