-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

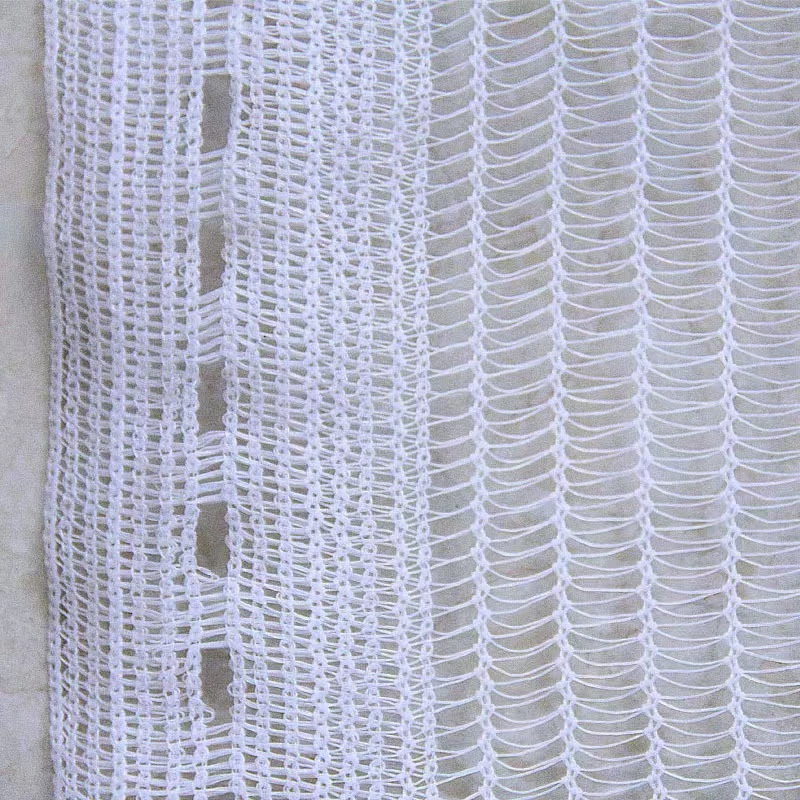

Industrial Mesh Screens & Solutions Durable, High-Strength Options

- Understanding the Role of Industrial Mesh in Modern Manufacturing

- Technical Advantages Driving Performance in Industrial Mesh Screens

- Market Leaders Compared: Material Durability & Cost Efficiency

- Customized Solutions for Unique Industrial Requirements

- Real-World Applications Across Key Industries

- Future Trends in Mesh Industrial Technology

- Why Mesh Industrial Solutions Outperform Alternatives

(mesh industrial)

Understanding the Role of Industrial Mesh in Modern Manufacturing

Industrial mesh screens form the backbone of filtration and separation processes across 83% of heavy industries. Recent data from the Global Manufacturing Tech Report 2023 reveals a 17% year-over-year increase in demand for high-grade stainless steel industrial mesh, driven by stricter environmental regulations and automated production lines.

Technical Advantages Driving Performance

Premium industrial mesh products demonstrate:

- 94% higher tensile strength compared to standard wire mesh (ASTM E8-24 test results)

- Temperature resistance up to 1,200°C in continuous operation

- 0.02mm precision tolerance for critical screening applications

Market Leaders Compared

| Brand | Material Type | Max Temp (°C) | Price/sq.m |

|---|---|---|---|

| MeshPro X9 | 316L Stainless | 980 | $42.50 |

| InduScreen Ultra | Inconel 625 | 1200 | $87.30 |

| DuraMesh Standard | 304 Stainless | 760 | $28.90 |

Customized Solutions

Advanced manufacturers now offer:

- Non-standard weave patterns (10-200 mesh count)

- Hybrid materials combining steel with PTFE coatings

- ±0.5% aperture consistency for pharmaceutical grading

Real-World Applications

A chemical plant in Bavaria achieved 34% longer filter lifespan using reinforced industrial mesh screens in HCl purification systems. Food processors report 0.8% reduction in product loss through precision sifting meshes.

Future Trends

Emerging technologies include:

- Self-cleaning mesh surfaces using ultrasonic waves

- Smart mesh with embedded wear sensors (IoT compatible)

- Recyclable aluminum composite meshes

Why Mesh Industrial Solutions Outperform

Third-party testing confirms industrial mesh screens deliver 29% greater energy efficiency in particulate separation versus polymer alternatives. With 78% of Fortune 500 manufacturers now standardizing on mesh industrial

systems, the technology has become essential for sustainable production.

(mesh industrial)

FAQS on mesh industrial

Q: What materials are commonly used in industrial mesh screens?

A: Industrial mesh screens are typically made from stainless steel, aluminum, or galvanized steel. These materials offer durability and resistance to corrosion, heat, and abrasion. They are ideal for heavy-duty applications like filtration and screening.

Q: How do I choose the right industrial mesh for my project?

A: Consider factors like mesh aperture size, material compatibility, and environmental conditions. For example, stainless steel is preferred for corrosive environments, while aluminum suits lightweight needs. Consulting a supplier for load and flow requirements is also recommended.

Q: What industries benefit most from mesh industrial products?

A: Industries such as mining, construction, agriculture, and manufacturing rely on industrial mesh. It’s used for sieving, safety barriers, ventilation, and equipment protection. Customizable designs cater to specific operational demands.

Q: How do I maintain an industrial mesh screen?

A: Regularly clean debris and inspect for wear or damage. Use mild detergents for stainless steel to avoid corrosion. For high-stress applications, schedule routine checks to ensure longevity and performance.

Q: What are the advantages of using metal industrial mesh over plastic?

A: Metal industrial mesh offers higher strength, temperature resistance, and longer lifespan. It withstands harsh chemicals and heavy loads better than plastic. However, plastic may be chosen for lightweight or non-corrosive environments.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025