-

Afrika

Afrika -

bahasa Albania

bahasa Albania -

Amharik

Amharik -

Arab

Arab -

orang Armenia

orang Armenia -

Azerbaijan

Azerbaijan -

Bahasa Basque

Bahasa Basque -

Belarusia

Belarusia -

Benggala

Benggala -

Bosnia

Bosnia -

Bulgaria

Bulgaria -

Katalan

Katalan -

Bahasa Cebu

Bahasa Cebu -

Cina

Cina -

Korsika

Korsika -

Kroasia

Kroasia -

Ceko

Ceko -

Orang Denmark

Orang Denmark -

Belanda

Belanda -

Bahasa inggris

Bahasa inggris -

Esperanto

Esperanto -

Estonia

Estonia -

Finlandia

Finlandia -

Perancis

Perancis -

Bahasa Frisia

Bahasa Frisia -

Galisia

Galisia -

orang Georgia

orang Georgia -

Jerman

Jerman -

Orang yunani

Orang yunani -

Bahasa Gujarati

Bahasa Gujarati -

Kreol Haiti

Kreol Haiti -

hausa

hausa -

Hawaii

Hawaii -

Ibrani

Ibrani -

Tidak

Tidak -

Bahasa Miao

Bahasa Miao -

Hongaria

Hongaria -

Islandia

Islandia -

orang Igbo

orang Igbo -

bahasa Indonesia

bahasa Indonesia -

orang Irlandia

orang Irlandia -

Italia

Italia -

Jepang

Jepang -

Jawa

Jawa -

Bahasa Kannada

Bahasa Kannada -

Bahasa Kazakh

Bahasa Kazakh -

Bahasa Khmer

Bahasa Khmer -

Rwanda

Rwanda -

Korea

Korea -

Kurdi

Kurdi -

Kirgistan

Kirgistan -

TBC

TBC -

Latin

Latin -

Latvia

Latvia -

Lithuania

Lithuania -

Luksemburg

Luksemburg -

Makedonia

Makedonia -

Malagasi

Malagasi -

Melayu

Melayu -

Bahasa Malayalam

Bahasa Malayalam -

Malta

Malta -

Maori

Maori -

Bahasa Marathi

Bahasa Marathi -

Mongolia

Mongolia -

Myanmar

Myanmar -

Nepal

Nepal -

Norwegia

Norwegia -

Norwegia

Norwegia -

orang oksitan

orang oksitan -

pasto

pasto -

Orang Persia

Orang Persia -

Polandia

Polandia -

Portugis

Portugis -

Bahasa Punjab

Bahasa Punjab -

Rumania

Rumania -

Rusia

Rusia -

Samoa

Samoa -

Gaelik Skotlandia

Gaelik Skotlandia -

Orang Serbia

Orang Serbia -

Bahasa inggris

Bahasa inggris -

Bahasa Shona

Bahasa Shona -

Bahasa Sindhi

Bahasa Sindhi -

Sinhala

Sinhala -

Orang Slovakia

Orang Slovakia -

Slovenia

Slovenia -

Somalia

Somalia -

Orang Spanyol

Orang Spanyol -

Sunda

Sunda -

Bahasa Swahili

Bahasa Swahili -

Orang Swedia

Orang Swedia -

bahasa Tagalog

bahasa Tagalog -

Bahasa Tajik

Bahasa Tajik -

Tamil

Tamil -

Bahasa Tatar

Bahasa Tatar -

Bahasa Telugu

Bahasa Telugu -

Thai

Thai -

Turki

Turki -

orang Turkmenistan

orang Turkmenistan -

Orang Ukraina

Orang Ukraina -

Bahasa Urdu

Bahasa Urdu -

Uighur

Uighur -

Uzbekistan

Uzbekistan -

Orang Vietnam

Orang Vietnam -

Bahasa Wales

Bahasa Wales -

Bantu

Bantu -

Yiddi

Yiddi -

Bahasa Yoruba

Bahasa Yoruba -

Bahasa Zulu-Sulul

Bahasa Zulu-Sulul

Why Construction Steel Mesh is the Backbone of Modern Infrastructure

In an era defined by rapid urbanization and infrastructural expansion, the demand for high-performance, cost-effective building materials has never been greater. Among the most essential components in civil engineering and construction today is construction steel mesh—a robust, adaptable reinforcement system used in everything from roads and bridges to residential buildings and retaining walls.

As the industry pivots toward long-lasting, environmentally conscious solutions, kawat kasa untuk konstruksi has become an indispensable player. Designed to optimize load distribution, crack resistance, and durability, modern construction mesh wire integrates engineering precision with industrial-grade materials to elevate structural integrity across diverse applications.

Construction Steel Mesh: Engineering Strength and Sustainability

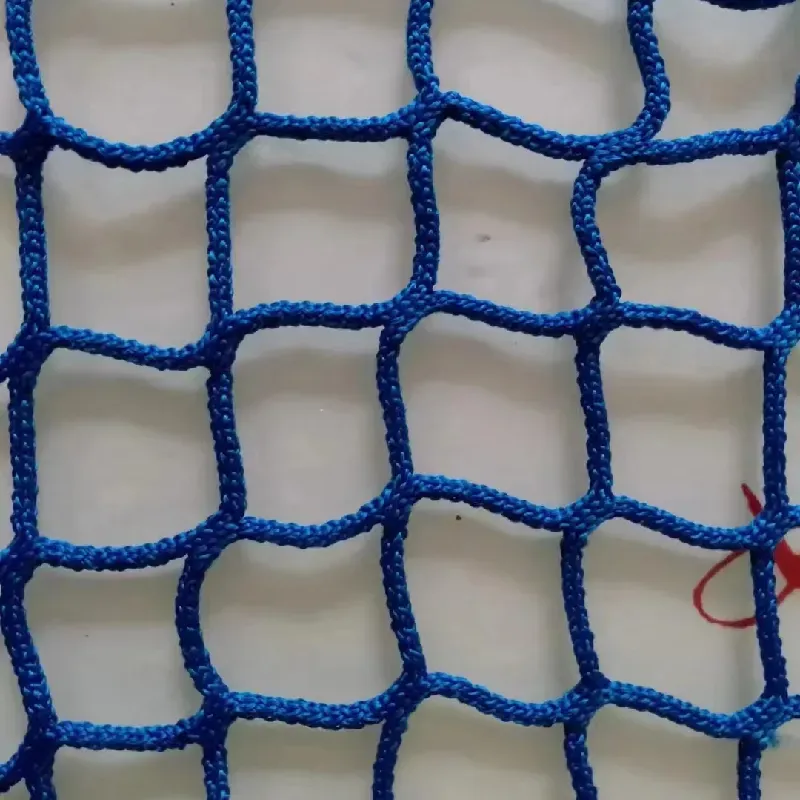

The core of any durable structure lies in its reinforcement. Construction steel mesh, manufactured from high-tensile, low-carbon steel, delivers unmatched strength and flexibility. Its grid pattern—created through welding or weaving—enables even load distribution and minimizes stress concentrations, thereby enhancing the performance of concrete in both compression and tension.

Ideal for foundations, slabs, beams, tunnels, and walls, construction steel mesh addresses a range of structural challenges. The mesh controls shrinkage, resists cracking, and provides a secure bond with poured concrete. Moreover, steel mesh improves construction efficiency by reducing the need for excessive rebar placement and speeding up the reinforcement process.

With advances in galvanization and coating technology, modern steel mesh also offers superior corrosion resistance. This makes it suitable for high-moisture environments, including marine and coastal infrastructure projects. The longevity and performance of construction steel mesh ultimately reduce maintenance costs and environmental impact—an important consideration in sustainable development.

Wire Mesh for Construction: Versatility Meets Precision

Whether you’re building a residential driveway or a high-rise tower, kawat kasa untuk konstruksi offers unmatched adaptability. Its use ranges from basic structural reinforcement to specialized applications like shotcrete support in tunnels or corrosion control in water-retaining structures. Available in welded or woven formats, wire mesh comes in a wide array of sizes, gauges, and materials.

Welded wire mesh—created by electronically welding intersecting wires—provides uniform strength and dimensional accuracy. It is often pre-cut and rolled, allowing for quick on-site installation with minimal labor. This format is ideal for slab-on-grade applications and precast concrete production. Woven mesh, on the other hand, offers greater flexibility, making it suitable for curved or irregular surfaces.

One of the most compelling features of wire mesh in construction is its customizability. Engineers can select specific mesh dimensions, wire diameters, and material coatings to match exact project requirements. For example, galvanized or epoxy-coated mesh enhances corrosion resistance, while stainless steel mesh supports high-load scenarios in industrial environments.

As building codes and quality standards evolve, so too does the technology behind wire mesh. Rigorous testing for tensile strength, elongation, weld shear, and corrosion performance ensures that kawat kasa untuk konstruksi meets the safety and performance demands of modern infrastructure.

Gabion Wire Specification: Stabilizing Structures with Earth and Steel

For applications that demand both structural reinforcement and natural aesthetics, gabions offer a compelling solution. A gabion is essentially a wire mesh cage filled with stone, used to control erosion, support slopes, or construct retaining walls. The key to their reliability lies in the gabion wire specification—a crucial factor that determines durability, flexibility, and environmental resistance.

Gabion mesh is typically made of galvanized or PVC-coated steel, often in hexagonal or welded formats. The mesh must maintain high tensile strength and excellent flexibility to conform to terrain without fracturing under pressure. A standard gabion wire specification includes measurements such as mesh aperture (commonly 80x100mm), wire diameter (usually between 2.7 to 4.0mm), and coating thickness.

PVC-coated gabion wires are especially suited for coastal, marine, or highly alkaline soil conditions, where long-term corrosion resistance is vital. The coating not only extends service life but also improves resistance to UV radiation and weathering.

Used in both civil engineering and landscaping, gabions help prevent landslides, stabilize road embankments, and beautify architectural spaces. The combination of geotechnical function and environmental harmony makes gabion structures a favorite among green infrastructure designers.

Wire Mesh in Construction: The Hidden Framework of Stability

Beneath every well-laid road, every high-rise slab, and every solid retaining wall is the unsung hero: wire mesh in construction. It performs the vital role of internal reinforcement, providing support against shrinkage, impact, vibration, and tensile loads. Whether embedded in concrete or used as a facing support, mesh is the silent backbone of resilient engineering.

In vertical applications like shear walls or curtain facades, mesh improves stress distribution and anchors concrete during curing. In slabs and floors, it minimizes curling and edge cracking by maintaining dimensional uniformity. For projects involving seismic zones or expansive soil conditions, specialized wire mesh grids absorb movement and reduce the risk of catastrophic failure.

Wire mesh in construction also aids in achieving faster project turnaround. Its modular nature and ease of placement allow for faster formwork setups, reduced labor costs, and enhanced site efficiency. Plus, its lightweight but high-strength design contributes to lower transport and handling costs—a critical factor in large-scale developments.

As infrastructure requirements grow more complex, wire mesh provides the flexibility and reliability necessary for long-term performance. When used correctly, it extends the life of buildings, reduces material fatigue, and ensures compliance with structural standards.

Construction Mesh Wire: Elevate Every Layer of Your Project

No matter the size or scope of your construction project, construction mesh wire ensures every layer is reinforced with strength and intelligence. From basement slabs to high-altitude towers, it fortifies structures against natural forces, operational stress, and the passage of time.

Modern construction mesh wire undergoes extensive testing for weld integrity, corrosion resistance, and load-bearing capacity. This means builders can trust it to deliver performance across a wide spectrum of environments—from arid deserts to coastal storm zones. Additionally, its compatibility with concrete admixtures and finishing tools ensures seamless integration into any construction plan.

Construction professionals today demand materials that are not only strong but also adaptable and sustainable. Construction mesh wire answers this call, providing a smart, scalable reinforcement system that supports the future of resilient infrastructure.

Construction Steel Mesh FAQs

What’s the main advantage of using construction steel mesh over traditional rebar?

Construction steel mesh offers faster installation, better crack control, and a more even distribution of structural load compared to rebar. It is especially effective in flat concrete elements like slabs and walls, where reinforcement over a wide area is required.

How do I choose the right gabion wire specification for my project?

Consider the environmental conditions, load demands, and intended lifespan of the structure. For high-moisture or coastal zones, PVC-coated or galvanized steel with thicker diameters (3.0mm–4.0mm) and tighter mesh apertures is recommended. Always ensure the mesh complies with ASTM or EN standards.

Can wire mesh for construction be used in vertical structures like walls?

Ya. Wire mesh in construction is commonly used in shear walls, retaining walls, and precast concrete panels. It enhances adhesion, resists cracking, and distributes loads more evenly than standalone concrete.

Is construction mesh wire suitable for DIY residential projects?

Absolutely. Pre-cut sheets or rolls of construction mesh wire are easy to transport and install, making them ideal for driveways, patios, sidewalks, and home extensions. However, it’s important to follow local building codes and use proper protective gear during installation.

How does wire mesh in construction improve durability?

By reinforcing concrete internally, wire mesh in construction prevents crack propagation, enhances resistance to external loads, and prolongs the structural lifespan. Its performance is especially valuable in areas subject to vibration, heavy loads, or temperature fluctuations.

-

The Sunshade Net Can Block Ultraviolet RaysBeritaAug.11,2025

-

Main Application and Technology of Nylon ScreenBeritaAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceBeritaAug.11,2025

-

Explore the Sunshade NetBeritaAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentBeritaAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureBeritaAug.11,2025