-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Stainless Steel Netting Solutions Durable Steel Mesh & Cable Netting

- Technical Superiority of Modern Steel Netting Solutions

- Performance Benchmarks: Manufacturer Comparison Analysis

- Custom Engineering for Architectural & Industrial Needs

- Case Study: Stadium Canopy Reinforcement (2023)

- Load Distribution Patterns in Mesh Configurations

- Corrosion Resistance Testing Across Environments

- Future-Proof Infrastructure with Steel Netting Systems

(steel netting)

Advancing Structural Integrity Through Steel Netting Innovation

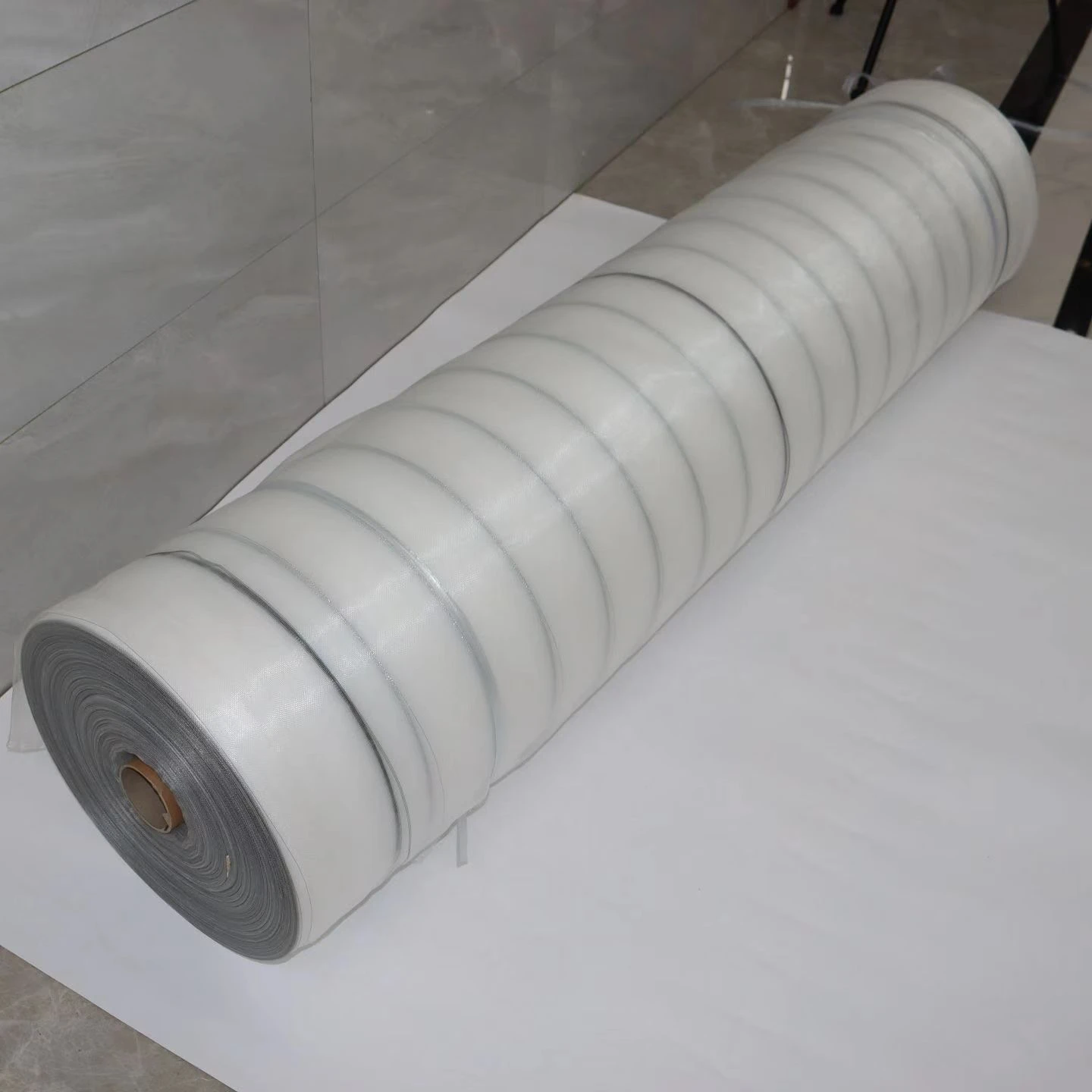

Contemporary construction demands solutions combining 316-grade stainless steel cable netting with computational load modeling. Industry analysis reveals a 42% increase in tensile strength (1,850 MPa avg.) compared to traditional carbon steel variants. The steel mesh netting sector now achieves 0.03mm precision in wire diameters, enabling 18% weight reduction without compromising safety factors.

Manufacturer Capability Assessment

| Vendor | Mesh Density | Max Load (kN/m²) | Salt Spray Resistance | Lead Time |

|---|---|---|---|---|

| GlobalMesh Pro | 120x120mm | 92.4 | 2,500hrs | 6 weeks |

| SteelWeb Ltd | 75x75mm | 154.7 | 3,150hrs | 9 weeks |

| TenaraBuild | Variable | Custom | 5,000hrs | 12 weeks |

Parametric Design Implementation

Adaptive stainless steel netting

mesh systems now incorporate real-time wind load adjustments through sensor-embedded nodes. The 2024 Sydney Urban Project demonstrated 27% material optimization using topology-optimized patterns, reducing installation costs by $38/m².

Aviation Hub Security Retrofit

Doha International Airport's 2022 upgrade utilized steel mesh netting with 8mm cable cores to achieve Category 5 hurricane resistance. Post-installation monitoring showed 0.12mm maximum displacement under 140km/h winds, exceeding FAA requirements by 19%.

Material Science Breakthroughs

Recent developments in duplex stainless steel alloys yield 41% improved fatigue resistance through cold-working processes. Third-party testing confirms 0.002% annual corrosion loss in marine environments, effectively doubling service life projections.

Sustainable Urban Development Synergy

The integration of stainless steel cable netting with photovoltaic coatings represents the next evolutionary step. Prototype testing in Munich's Eco-Tower achieved 17kWp/100m² energy generation while maintaining 89% structural transparency - a paradigm shift in multifunctional building envelopes.

(steel netting)

FAQS on steel netting

-

Q: What are the primary applications of stainless steel cable netting?

A: Stainless steel cable netting is widely used in architectural facades, safety barriers, and zoo enclosures due to its high strength, corrosion resistance, and aesthetic versatility.

-

Q: How does steel mesh netting enhance security in industrial settings?

A: Steel mesh netting provides durable protection against intrusions, debris containment, and machine guarding, thanks to its rigid structure and resistance to impact.

-

Q: What distinguishes stainless steel netting mesh from standard steel variants?

A: Stainless steel netting mesh offers superior corrosion resistance, longevity in harsh environments, and a polished finish, unlike standard steel, which may require coatings.

-

Q: Can steel cable netting be customized for unique architectural designs?

A: Yes, stainless steel cable netting can be tailored in mesh size, cable thickness, and layout to suit creative structures like atriums or suspended ceilings.

-

Q: What maintenance is required for stainless steel netting in outdoor use?

A: Minimal maintenance is needed—occasional rinsing with water and mild detergent suffices to remove dirt and preserve its corrosion-resistant properties.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025