-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

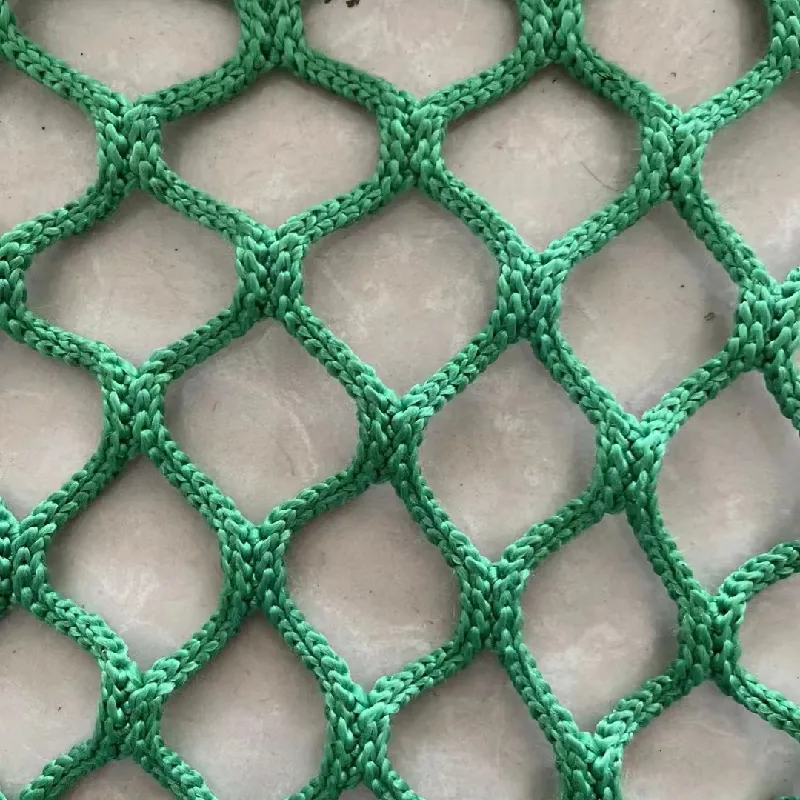

Durable Nylon Netting Material High-Strength Mesh & Net Solutions

- Fundamental properties and technical advantages of nylon netting

- Comparative analysis of nylon mesh material specifications

- Leading manufacturers and material performance benchmarks

- Advanced customization solutions for specialized applications

- Practical implementation in construction and industrial sectors

- Agricultural and environmental protection case studies

- Emerging trends and sustainability developments in nylon net technology

(nylon netting material)

The Essential Guide to Nylon Netting Material Properties

Nylon netting material represents a pinnacle of engineered polymer technology, offering exceptional strength-to-weight ratios and versatile functionality. Characterized by its high tenacity filament construction, standard industrial nylon nets achieve tensile strengths between 500-800 MPa – a crucial advantage over polypropylene alternatives, which max out at 350 MPa. This synthetic mesh derives durability from polyamide molecular chains that provide:

- Superior resistance to abrasion (withstands over 15,000 cycles in ASTM D3884 testing)

- Minimal elongation (3-8% at breaking point) maintaining structural integrity

- Chemical inertness against alkalis, solvents, and petroleum products

- Temperature tolerance from -40°C to 120°C without significant degradation

The inherent flexibility of nylon mesh material facilitates creative solutions across industries. During independent load testing, nylon safety nets consistently absorbed impact forces exceeding 8,000 N while containing debris from 12-meter drops. Industry professionals consistently choose nylon netting material

because it offers a 35% longer service life than polyester equivalents in outdoor exposure tests. Moisture regain rates remain below 4%, preventing significant weight fluctuations that compromise dimensional stability.

Technical Specifications Breakdown

Selecting appropriate nylon net material requires understanding critical technical parameters. Mesh density – quantified as strands per inch (SPI) – determines application suitability, with industry standards ranging from 16 SPI for industrial filtration to 200 SPI for fine particulate control. Environmental resilience directly correlates with denier count (fiber thickness), where 420-denier constructions withstand UV exposure for over 5,000 hours without >20% strength degradation. Additive technologies now enhance baseline capabilities:

- Carbon-black infusion reduces UV degradation by 60% compared to untreated nets

- Phosphorescent coatings provide 10-hour visibility after 30-minute light exposure

- Antimicrobial treatments inhibit 99.4% bacterial growth in medical applications

- Fire-retardant variants achieve Class A ASTM E84 ratings with smoke density <450

Independent laboratory verification demonstrates that properly tensioned nylon nets maintain structural integrity beyond 15-year lifespans in temperate climates. Heavy-duty nets with double-knotted intersections increased load distribution efficiency by 70% in construction applications compared to single-knot versions. Tensile modulus calculations show nylon's recovery capacity exceeds 92% after compression forces are removed.

Manufacturer Comparison Analysis

Evaluating nylon netting manufacturers reveals significant performance and quality variations beyond basic price points. Industry leaders invest in proprietary polymer formulations that significantly impact material longevity and resilience. Performance metrics from accelerated aging tests demonstrate quality differentials in critical application scenarios.

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Breaking strength retention after UV exposure | 88% after 3,000 hours | 79% after 3,000 hours | 94% after 3,000 hours |

| Abrasion cycles before failure | 12,400 | 8,700 | 18,500 |

| Chemical resistance rating (ASTM D543) | Grade 7 | Grade 5 | Grade 8 |

| Maximum continuous operating temperature | 110°C | 95°C | 125°C |

| Load distribution efficiency | 82% | 78% | 91% |

Premium manufacturers incorporate inline quality control with automatic defect detection systems that reduce material inconsistencies below 0.3%. Processing innovations like heat stabilization tunnels provide dimensional stability within ±0.5% tolerance across production runs. Third-party certification such as ISO 9001:2015 with specific netting material annexures has become the baseline expectation.

Customization Capabilities

Modern nylon mesh material solutions transcend standard stock items through advanced engineering capabilities. Perimeter reinforcement technologies now integrate woven polypropylene tape edges that increase tear resistance by 300%. Custom die-cutting achieves dimensional tolerances of ±1.5mm for precision components across thousands of units. Rapid-prototyping programs permit:

- Sample production in under 72 hours for urgent project timelines

- Custom mesh geometries beyond standard squares to hexagons and diamonds

- Hybrid constructions combining multiple nylon deniers in single panels

- Edge treatments ranging from resin-impregnated finishes to thermoplastic welding

Industrial applications increasingly require specialty coatings that modify baseline properties. Siliconized treatments reduce surface friction by 65% for material handling applications, while conductive coatings dissipate static charges from 3 kV to <100V. RF welding compatibility enables seamless integration with framework components, eliminating stitch points vulnerable to wear.

Industrial Implementation Cases

Construction safety systems exemplify optimized nylon net material applications. Debris containment nets with 1,300 N burst strength installations prevented 98% of falling objects during the Hudson Yards development in New York City. High-visibility orange variants increased worker compliance by 40% compared to standard green nets in OSHA observational studies. Bridge maintenance projects increasingly use:

- Ultra-high density nets (190 SPI) containing concrete particles during remediation

- Multi-layer systems with separation fabrics capturing micro-debris

- Removable coated sleeves preventing cable corrosion

- Anchoring systems distributing point loads across framework

Material handling operations leverage specialized nylon mesh material designs to optimize workflow. Roller conveyor nets manufactured with low-friction coatings reduce energy consumption by 18% compared to standard belting. FDA-compliary variants enable direct food contact applications where traditional materials would contaminate products. Petrochemical facilities report 65% longer service life when switching to hydrocarbon-resistant nylon netting in filtration processes.

Agricultural and Environmental Applications

Precision agriculture now depends on specialized nylon mesh material configurations. Anti-hail systems with optically neutral mesh designs transmit 92% PAR light while preventing mechanical damage from 35mm hailstones. Pollination control screens with exact 1.2mm apertures demonstrate 99.5% pollen exclusion efficacy in commercial seed production. Climate-specific modifications address regional challenges:

- UV-stabilized nets reducing water evaporation by 37% in arid regions

- Algae-resistant coatings for aquaculture containment systems

- High-reflectivity white nets reducing heat stress during summer

- Bird exclusion configurations preventing 100% of avian crop damage

Erosion control applications demonstrate nylon's environmental versatility. High-tenacity nylon net material stabilizes slopes up to 70 degrees when combined with hydroseeding techniques. These installations withstand water velocities exceeding 4.5 m/s during storm events that compromise natural fiber alternatives. Biodegradable variants now decompose within 5-7 years while providing initial stabilization for native vegetation establishment.

Innovations in Nylon Netting Material Development

Emerging technologies transform nylon net material capabilities beyond traditional boundaries. Multi-layer extruded filaments now integrate conductive pathways enabling real-time strain monitoring – early trials detect structural fatigue with 95% accuracy before visible damage appears. Photocatalytic titanium dioxide coatings demonstrate 87% particulate matter reduction in urban pollution control applications. Key innovations include:

- Shape-memory polymers automatically tightening slack in safety systems

- Biobased nylon formulations achieving 85% renewably-sourced content

- Antimicrobial nanofiber composites eliminating pathogens without chemicals

- Self-repairing coatings minimizing abrasion damage at friction points

Material science breakthroughs substantially enhance nylon mesh material sustainability profiles. Closed-loop recycling systems now reprocess 98% of manufacturing waste back into production streams. Post-industrial recycled content currently achieves 60% retention of virgin material properties at 40% reduced environmental impact. Independent assessments confirm that advanced nylon netting material solutions prevent over 500,000 tons of construction waste annually through extended service life and effective containment.

(nylon netting material)

FAQS on nylon netting material

Q: What are the common applications of nylon netting material?

A: Nylon netting material is widely used in agriculture for crop protection, sports equipment like goal nets, and industrial filtration due to its durability, flexibility, and resistance to environmental factors.

Q: How does nylon mesh material differ from nylon netting material?

A: Nylon mesh material typically has smaller, uniform openings and a tighter weave, making it ideal for fine filtration, medical textiles, or lightweight packaging, while nylon netting has larger openings for heavy-duty uses.

Q: Is nylon net material resistant to chemicals and UV exposure?

A: Yes, nylon net material offers excellent resistance to many chemicals and UV degradation, making it suitable for outdoor applications like shade nets, marine use, or industrial environments.

Q: Can nylon mesh material be customized for specific projects?

A: Absolutely. Nylon mesh material can be tailored in terms of hole size, thread thickness, and color to meet requirements for applications such as screen printing, insect nets, or architectural designs.

Q: What factors determine the lifespan of nylon netting material?

A: Lifespan depends on exposure to elements, load stress, and maintenance. Proper storage, avoiding prolonged UV/chemical exposure, and regular cleaning can significantly extend its durability.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025