-

africano

africano -

albanese

albanese -

Amarico

Amarico -

Arabo

Arabo -

armeno

armeno -

Azero

Azero -

Basco

Basco -

bielorusso

bielorusso -

bengalese

bengalese -

Bosniaco

Bosniaco -

bulgaro

bulgaro -

catalano

catalano -

Cebuano

Cebuano -

Cina

Cina -

Corso

Corso -

croato

croato -

ceco

ceco -

danese

danese -

Olandese

Olandese -

Inglese

Inglese -

esperanto

esperanto -

Estone

Estone -

finlandese

finlandese -

francese

francese -

Frisone

Frisone -

galiziano

galiziano -

georgiano

georgiano -

Tedesco

Tedesco -

greco

greco -

Gujarati

Gujarati -

Creolo haitiano

Creolo haitiano -

haussa

haussa -

hawaiano

hawaiano -

ebraico

ebraico -

No

No -

Miao

Miao -

ungherese

ungherese -

islandese

islandese -

Igbo

Igbo -

indonesiano

indonesiano -

irlandesi

irlandesi -

Italiano

Italiano -

giapponese

giapponese -

giavanese

giavanese -

Italiano:

Italiano: -

kazako

kazako -

khmer, lingua cambogiana

khmer, lingua cambogiana -

Ruandese

Ruandese -

coreano

coreano -

curdo

curdo -

Kirghizistan

Kirghizistan -

TBC

TBC -

latino

latino -

lettone

lettone -

lituano

lituano -

lussemburghese

lussemburghese -

macedone

macedone -

malgascio

malgascio -

malese

malese -

Malayalam

Malayalam -

maltese

maltese -

Maori

Maori -

Italiano:

Italiano: -

mongolo

mongolo -

Birmania

Birmania -

nepalese

nepalese -

norvegese

norvegese -

norvegese

norvegese -

occitano

occitano -

Pashtu

Pashtu -

persiano

persiano -

Polacco

Polacco -

portoghese

portoghese -

Punjabi

Punjabi -

rumeno

rumeno -

russo

russo -

Samoano

Samoano -

Gaelico Scozzese

Gaelico Scozzese -

serbo

serbo -

Inglese

Inglese -

Shona

Shona -

Sindhi

Sindhi -

Singalese

Singalese -

slovacco

slovacco -

sloveno

sloveno -

Somalo

Somalo -

spagnolo

spagnolo -

Sundanese

Sundanese -

swahili

swahili -

svedese

svedese -

Tagalog

Tagalog -

Tagico

Tagico -

Italiano:

Italiano: -

Tartaro

Tartaro -

Telugu

Telugu -

tailandese

tailandese -

Turco

Turco -

turkmeno

turkmeno -

ucraino

ucraino -

Italiano:

Italiano: -

Uiguro

Uiguro -

Uzbeco

Uzbeco -

vietnamita

vietnamita -

gallese

gallese -

Aiuto

Aiuto -

yiddish

yiddish -

Iorubà

Iorubà -

Zulù

Zulù

The Ultimate Solution for Versatile Industrial and Consumer Applications

In today’s rapidly evolving industries, materials that blend durability, flexibility, and customizability are indispensable. Among these, schermo in rete di nylon E rete di nylon stand out as remarkably versatile products, utilized across sectors from manufacturing and agriculture to crafts and household uses. Whether you are sourcing nylon netting by the yard for custom projects or seeking specialized nylon netting for scrubbies, the range of applications is vast.

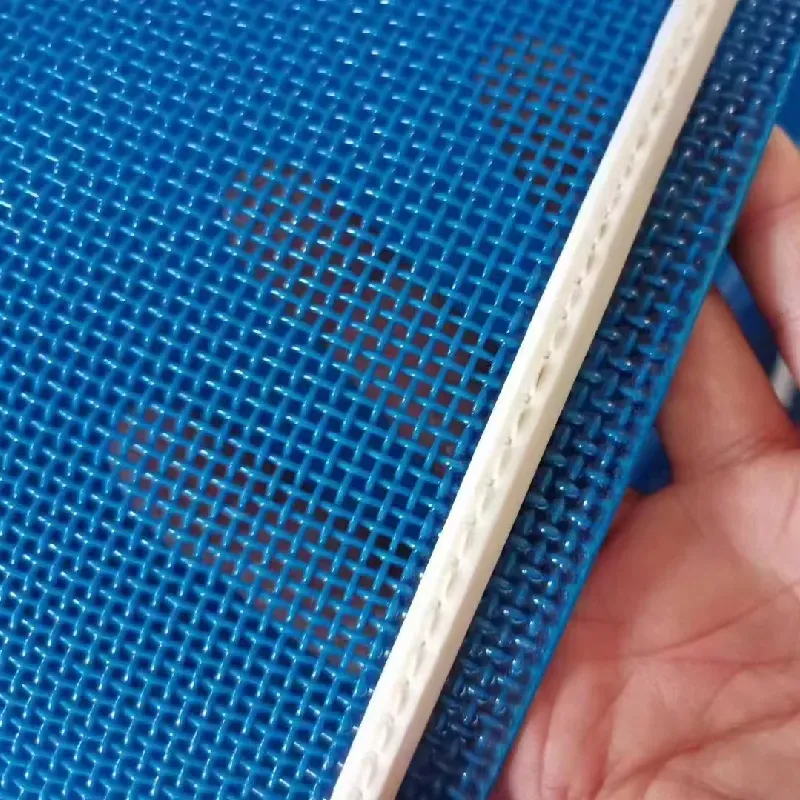

One of the defining advantages of nylon mesh is its ability to be processed into various shapes and sizes, including annular mesh belts and bespoke mesh bags. The edge wrapping or edge brushing processes with glue help prevent wire stripping, ensuring longevity and reliable performance. Additionally, options like black nylon netting E maglia di nylon fine offer aesthetic and functional diversity, fitting seamlessly into numerous scenarios.

Nylon Mesh Screen: Precision and Durability for Industrial Excellence

A schermo in rete di nylon is a critical component in many industrial and commercial processes due to its combination of strength and filtration capabilities. Used extensively in food processing, chemical industries, and water treatment plants, the nylon mesh screen offers fine filtering while maintaining structural integrity under stress.

Its weave can be tailored to suit filtration needs, ranging from coarse mesh that filters larger particles to ultra-fine mesh ideal for air or liquid filtration. Nylon’s natural resistance to chemicals and abrasion makes it a superior choice over metal screens in environments where corrosion is a risk.

Moreover, nylon mesh screens can be fabricated into annular belts or framed screens, accommodating specific machinery or system requirements. The ability to customize mesh aperture size and density ensures optimal flow rates and efficiency in filtration systems.

Nylon Netting by the Yard: Custom Solutions for Diverse Projects

For industries and hobbyists alike, purchasing nylon netting by the yard offers unmatched flexibility. This allows users to buy exactly the length and width they require without excess waste, enabling precise project planning and cost control.

Nylon netting by the yard can be selected based on mesh size, thickness, color, and treatment options. Whether it’s for agricultural use, packaging, protective barriers, or even crafting, the availability of yardage supports both large-scale manufacturing and individual creative projects.

The fabric can be further processed, with edge wrapping or brushing to reinforce and prevent unraveling, making it easier to handle and sew. This feature is particularly valued when creating reusable mesh bags, protective covers, or custom-made screens.

Nylon Netting for Scrubbies: Durable and Hygienic Cleaning Solutions

Among the many consumer uses of nylon netting, one niche yet essential application is nylon netting for scrubbies. Nylon’s resilience to wear and tear, combined with its ability to dry quickly and resist mildew, makes it ideal for scrubbing pads used in kitchens and bathrooms.

Nylon netting for scrubbies is usually produced with a fine or medium mesh size that provides the perfect balance between gentle cleaning and effective abrasion. It withstands frequent use and can be fashioned into various shapes, including round or square pads, or layered designs.

This nylon material is also easy to wash, ensuring hygiene and longevity. Its synthetic nature allows for color customization, with black nylon netting often preferred for scrubbies as it hides stains and retains a clean appearance after repeated use.

Black Nylon Netting: Combining Aesthetics with Functionality

Black nylon netting is not only popular for its sleek appearance but also for its practical advantages. The dark color provides UV protection, enhancing durability when used outdoors or in direct sunlight. It also offers better concealment in applications requiring discreet netting, such as window screens or insect barriers.

In commercial and industrial contexts, black nylon netting helps reduce glare and improve visibility of objects behind the mesh. Its aesthetic versatility means it is frequently used in fashion accessories, sports gear, and architectural designs where appearance is as important as performance.

The processing methods such as edge wrapping or glue brushing help maintain the integrity of black nylon netting, especially when cut into customized shapes or used in demanding environments.

Fine Nylon Mesh: Precision Crafting for Sensitive and Delicate Tasks

When filtration, separation, or protection requires an ultra-fine mesh, maglia di nylon fine emerges as the preferred choice. Its tightly woven threads create a delicate yet durable fabric ideal for laboratory screens, insect nets, food strainers, and delicate packaging.

The fine nylon mesh can be easily cut, sewn, or laminated into mesh bags or screens of any shape. The edge sealing options prevent wire stripping, crucial when the mesh is handled repeatedly or subjected to tension.

In consumer products, fine nylon mesh is favored for crafting facial scrubbies, sheer curtains, and decorative items, while in industrial applications, it offers reliable performance in filtering microscopic particles or controlling pest entry.

Nylon Mesh Netting FAQs

What advantages does nylon mesh screen offer over metal screens?

Nylon mesh screen is corrosion-resistant, lightweight, and flexible, making it ideal for applications where metal may rust or become brittle. It also offers ease of customization and is less abrasive on filtered materials, extending equipment life.

Can nylon netting by the yard be customized to specific project needs?

Yes, buying nylon netting by the yard provides flexibility to choose length, width, mesh size, and color. This customization reduces waste and enables precise tailoring for applications ranging from industrial filters to craft projects.

Why is nylon netting preferred for scrubbies?

Nylon netting’s durability, quick-drying nature, and resistance to mildew make it perfect for scrubbies. It withstands frequent abrasion and cleaning, maintaining effectiveness and hygiene over time.

What are the benefits of black nylon netting compared to other colors?

Black nylon netting offers enhanced UV resistance, reduces glare, hides dirt and stains, and adds a sleek appearance. These benefits make it especially suitable for outdoor use and applications where appearance matters.

How fine can nylon mesh be made for delicate uses?

Fine nylon mesh can be woven tightly enough to filter microscopic particles or serve as insect-proof barriers. It retains durability while being delicate, making it suitable for applications from laboratory screens to cosmetic scrubbies.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNotiziaJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNotiziaJun.27,2025

-

Maximize Your Harvest with Smart NetNotiziaJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNotiziaJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNotiziaJun.27,2025