-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

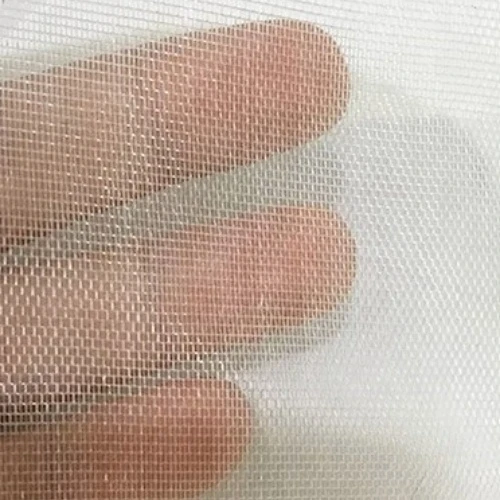

filter steel mesh

Understanding Filter Steel Mesh Applications, Benefits, and Types

Filter steel mesh is an essential industrial material utilized in various applications, ranging from water treatment to food processing. Its strength, durability, and filtration capabilities make it a popular choice in many sectors. This article will explore what filter steel mesh is, its benefits, and its different types, highlighting its role in modern industries.

What Is Filter Steel Mesh?

Filter steel mesh, also known as stainless steel mesh or wire mesh, is a material made from woven or welded steel wires. The openings in the mesh can vary in size depending on the intended application, ranging from very fine to coarse. The primary purpose of filter steel mesh is to separate solids from liquids or gases, ensuring that only the desired elements pass through. Due to its robust physical properties, it is highly resistant to corrosion, heat, and mechanical strain, making it suitable for various demanding environments.

Applications of Filter Steel Mesh

1. Water Treatment One of the most common applications of filter steel mesh is in water treatment facilities, where it is used to remove impurities from water. The mesh helps filter out suspended solids, debris, and other contaminants, ensuring the water is clean and safe for consumption or industrial use.

2. Food Processing In food production, filter steel mesh is highly valued for its ability to maintain sanitary conditions. It is used to filter liquids, such as juices and oils, removing particles that may spoil the product or affect its quality.

3. Chemical Industry Chemicals often require strict filtration to ensure that unwanted substances are removed during production processes. Filter steel mesh is commonly employed in various chemical applications, helping maintain product integrity and safety.

4. Pharmaceuticals The pharmaceutical industry relies heavily on filter steel mesh for various purposes, including sterilizing equipment and ensuring that products meet safety standards. The mesh helps remove contaminants and ensures a high level of purity in finished products.

5. Mining and Aggregates In mining, filter steel mesh is used to separate minerals from unwanted materials. It plays a crucial role in improving the efficiency of mineral extraction and processing, allowing for better quality control.

Benefits of Using Filter Steel Mesh

1. Durability Steel is inherently strong, which means filter steel mesh provides long-lasting performance even under extreme conditions. Its resistance to corrosion and wear enhances its lifespan, making it a cost-effective choice over time.

filter steel mesh

2. Versatility Filter steel mesh can be manufactured in a variety of sizes and specifications, making it suitable for diverse applications. Whether for fine filtration in pharmaceuticals or coarse filtration in mining, there is a type of steel mesh tailored to meet specific needs.

3. Efficiency The woven structure of the mesh allows for efficient flow through the material, ensuring that processes like filtration and separation occur rapidly and effectively.

4. Low Maintenance Compared to other filtration systems, filter steel mesh requires minimal maintenance. Regular cleaning is often enough to keep it functioning optimally, saving time and resources for industries.

5. Cost-Effectiveness While the initial investment in high-quality filter steel mesh may be higher than alternative filtration methods, its durability and low maintenance make it a cost-effective choice in the long run.

Types of Filter Steel Mesh

There are several types of filter steel mesh, each designed for specific applications

- Woven Wire Mesh Made by weaving wires together, this type of mesh is commonly used in applications that require high filtration accuracy. The mesh's tightness can be adjusted by changing the thickness of the wires and the weave pattern.

- Welded Wire Mesh This mesh is created by welding wires at intersections. It offers enhanced strength and is commonly used in construction, fencing, and filtration applications where durability is crucial.

- Perforated Metal Although not a mesh in the traditional sense, perforated metal sheets with holes can also serve a similar purpose, allowing larger particulates to be filtered out while providing structural support for various applications.

Conclusion

Filter steel mesh is a vital component in numerous industries, offering a combination of strength, efficiency, and adaptability. As technology advances, the importance of effective filtration remains paramount, making filter steel mesh an indispensable tool in achieving clean, safe, and high-quality processes across sectors. Whether for water treatment, food processing, or chemical manufacturing, filter steel mesh plays a significant role in maintaining industrial standards and enhancing product quality.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025