-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding Wire Mesh Gauge and Its Importance in Various Applications

Understanding the Gauge of Wire Mesh A Comprehensive Guide

Wire mesh is an essential material used in diverse industries and applications, from construction to agriculture, and even in home projects. One of the most critical factors to consider when selecting wire mesh is its gauge, which refers to the thickness of the wire used in the mesh. This article will explore the significance of wire mesh gauge, its measurement, and how it affects the material's performance.

What is Wire Mesh Gauge?

The gauge of wire mesh is typically measured using two different systems the American Wire Gauge (AWG) and the Standard Wire Gauge (SWG). The gauge number is inversely proportional to the wire's diameter as the gauge number increases, the diameter decreases. For instance, an 18-gauge wire has a larger diameter than a 24-gauge wire. Understanding these measurements is crucial for selecting the appropriate wire mesh for specific applications.

Importance of Wire Gauge in Wire Mesh

1. Strength and Durability The wire gauge directly influences the strength and durability of wire mesh. Thicker wires (lower gauge numbers) provide greater strength, making them suitable for heavy-duty applications such as fencing, reinforcing concrete, and industrial use. Conversely, thinner wires (higher gauge numbers) may be more appropriate for lighter applications.

2. Weight and Flexibility The thickness of the wire also affects the weight and flexibility of the mesh. Thicker wires may add significant weight, which could be a consideration for projects where ease of handling and installation is essential. Thinner wires, while equating to less weight, may also bend or flex more easily, which could either be advantageous or disadvantageous depending on the application.

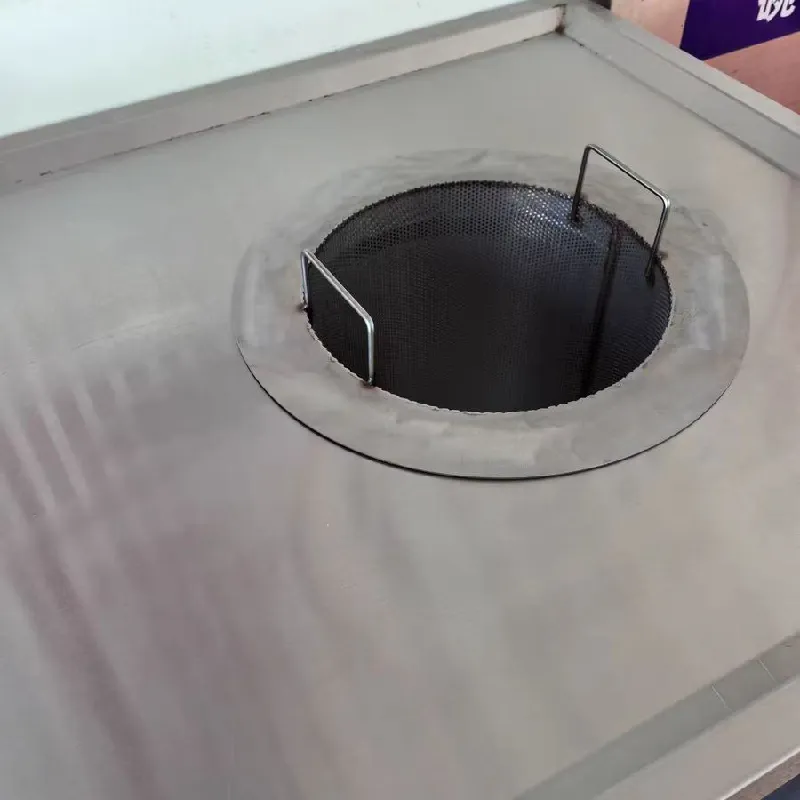

gauge of wire mesh

3. Aesthetic Considerations In architectural applications, the wire mesh's appearance can play a vital role. Thinner wires create a more delicate look, which can be more visually appealing in certain contexts, such as decorative fencing, art installations, or as a building facade. However, thicker wire may provide a more robust and industrial appearance, suitable for other purposes.

4. Cost Generally, thicker wire mesh tends to be more expensive than thinner options. However, considering the specific project's needs and balancing costs with desired performance characteristics is crucial. Investing in a higher gauge wire mesh could lead to lower maintenance and replacement costs over time.

Selecting the Right Wire Mesh Gauge

Choosing the right wire mesh gauge depends largely on the specific requirements of your project. For heavy-duty applications like construction or security fencing, a lower gauge (e.g., 10 to 14) may be necessary to provide the strength needed. In contrast, for gardening, poultry enclosures, or decorative purposes, a higher gauge (e.g., 16 to 22) may suffice and provide a cost-effective solution.

It's also essential to consider other factors in conjunction with wire gauge, such as the type of material (e.g., galvanized steel, stainless steel), the intended environment (e.g., outdoor exposure, chemical exposure), and any specific regulatory requirements that may apply to your project.

Conclusion

The gauge of wire mesh is a critical consideration in selecting the right material for your needs. By understanding how wire gauge affects strength, flexibility, aesthetics, and cost, you can make an informed decision that enhances the efficacy of your project. Whether you're working on a large-scale industrial project or a small DIY endeavor, choosing the right gauge of wire mesh will ultimately contribute to the success of your efforts.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025