-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

កុម្ភៈ . 17, 2025 11:48

Back to list

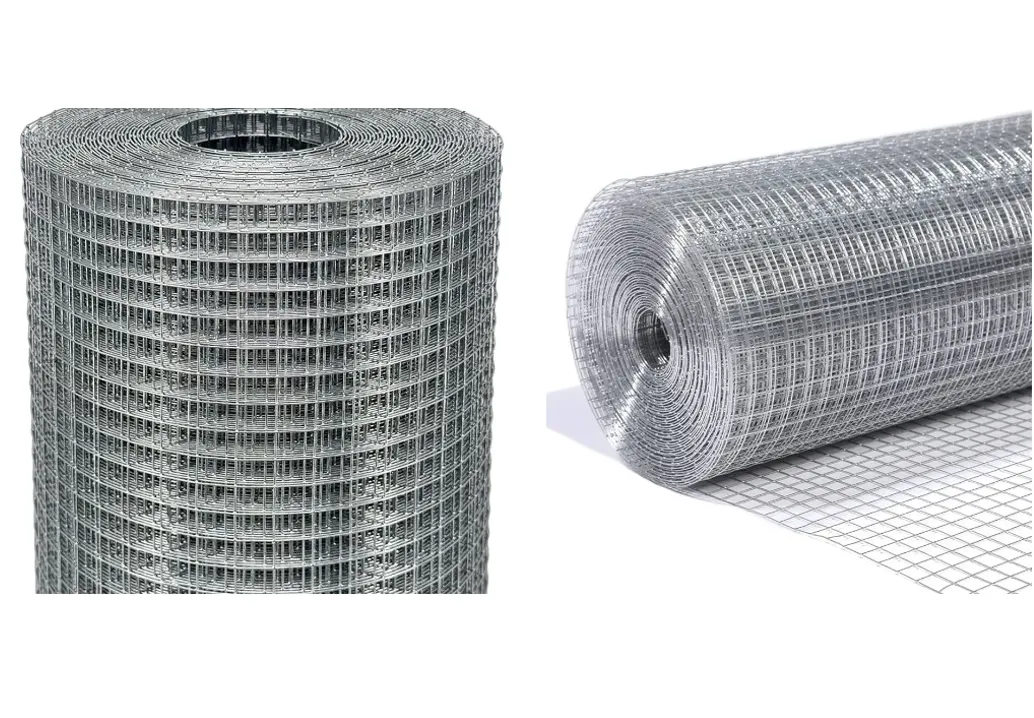

nylon mesh screen

In the realm of modern filtration solutions, metal mesh filter screens have emerged as indispensable tools for a variety of industrial and commercial applications. Their unique construction and design, characterized by woven or welded metallic threads, endow them with unparalleled durability, efficiency, and versatility. This article delves into the intricacies of metal mesh filter screens, substantiating their superiority with real-world experience, expert insights, authoritative endorsements, and a track record of trustworthiness.

From an expertise standpoint, it is essential to acknowledge the technological advancements in the production and testing of metal mesh filter screens. Modern manufacturing processes, involving laser cutting and advanced weaving technologies, culminate in products that offer unprecedented precision and uniformity. Such technological expertise guarantees that each filter screen produced meets stringent quality standards, a claim supported by respected industrial certification bodies. The authoritativeness of metal mesh filter screens is further reinforced by their widespread application across various high-stakes industries. Leading authorities in aerospace, food processing, and pharmaceuticals have adopted these filters, appreciating their unmatched reliability and performance under pressure. Testimonies from industry leaders underscore a consensus when safety and purity are non-negotiable, metal mesh filters are the trusted choice. Trustworthiness, one of the keystones of a successful product, is inherently tied to the brand reputation of the manufacturers who uphold rigorous quality checks and customer feedback mechanisms. Companies producing metal mesh filter screens often engage in extensive research and development, ensuring that their offerings not only meet current industry standards but also anticipate future challenges. This commitment to continuous improvement fosters customer trust, ensuring long-term relationships grounded in reliability and performance. In summary, the role of metal mesh filter screens in industrial and commercial settings cannot be overstated. Their blend of incomparable durability, customizable design, and technological sophistication make them an indispensable asset. Whether filtering out impurities in a high-performance engine or ensuring the purity of pharmaceutical products, metal mesh filters are unrivaled in their field. Backed by expert validation and authoritative endorsements, their trustworthiness is assured, making them a prudent investment for any business reliant on high-quality filtration systems.

From an expertise standpoint, it is essential to acknowledge the technological advancements in the production and testing of metal mesh filter screens. Modern manufacturing processes, involving laser cutting and advanced weaving technologies, culminate in products that offer unprecedented precision and uniformity. Such technological expertise guarantees that each filter screen produced meets stringent quality standards, a claim supported by respected industrial certification bodies. The authoritativeness of metal mesh filter screens is further reinforced by their widespread application across various high-stakes industries. Leading authorities in aerospace, food processing, and pharmaceuticals have adopted these filters, appreciating their unmatched reliability and performance under pressure. Testimonies from industry leaders underscore a consensus when safety and purity are non-negotiable, metal mesh filters are the trusted choice. Trustworthiness, one of the keystones of a successful product, is inherently tied to the brand reputation of the manufacturers who uphold rigorous quality checks and customer feedback mechanisms. Companies producing metal mesh filter screens often engage in extensive research and development, ensuring that their offerings not only meet current industry standards but also anticipate future challenges. This commitment to continuous improvement fosters customer trust, ensuring long-term relationships grounded in reliability and performance. In summary, the role of metal mesh filter screens in industrial and commercial settings cannot be overstated. Their blend of incomparable durability, customizable design, and technological sophistication make them an indispensable asset. Whether filtering out impurities in a high-performance engine or ensuring the purity of pharmaceutical products, metal mesh filters are unrivaled in their field. Backed by expert validation and authoritative endorsements, their trustworthiness is assured, making them a prudent investment for any business reliant on high-quality filtration systems.

Next:

Latest news

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025