-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

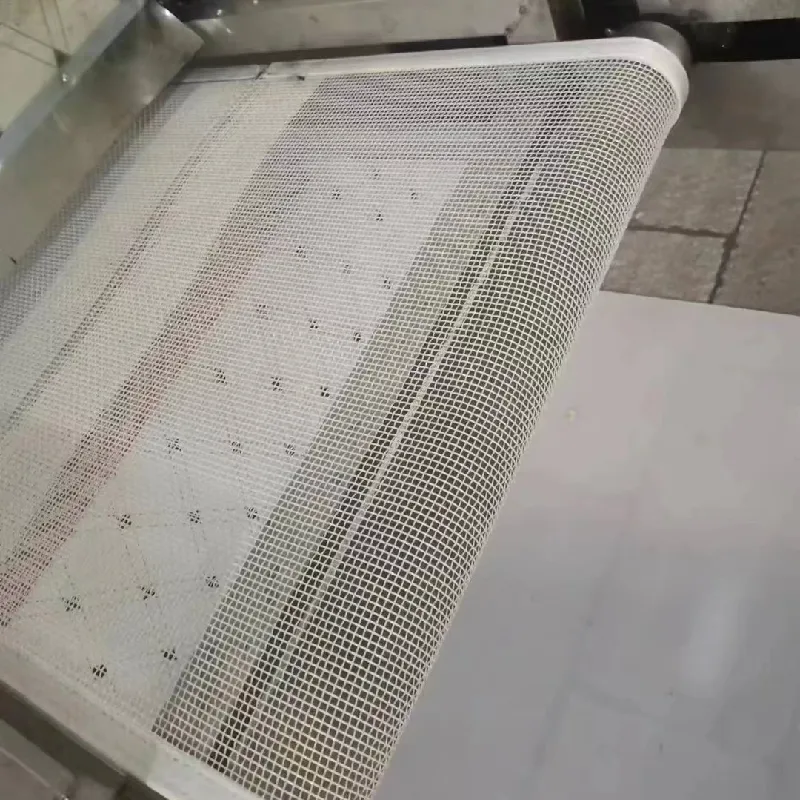

mining mesh

Understanding Mining Mesh A Crucial Component in Modern Mining Operations

Mining has evolved significantly over the years, requiring advanced technologies and materials to enhance efficiency and safety. One such critical component in the mining industry is mining mesh, a versatile tool used predominantly in underground mining operations. This article delves into the importance, applications, and advancements of mining mesh, highlighting its role in ensuring safer and more effective mining processes.

At its core, mining mesh is a type of fabric or netting that is designed to provide support and stability to the walls and ceilings of underground mines. Composed typically of steel wire, mining mesh is engineered to withstand extreme conditions and heavy loads. Its primary function is to prevent rock falls, a significant hazard in underground mining that can lead to injuries, fatalities, and costly downtimes. By reinforcing the structural integrity of mine shafts and tunnels, mining mesh plays a pivotal role in protecting the workforce and ensuring continuous operations.

The applications of mining mesh extend beyond just rock support. It is also utilized in the transportation and handling of materials within the mine. For instance, mesh can be used to create safety barriers, control dust, and segregate different areas of a mining site. Additionally, mining mesh allows for effective drainage, preventing water accumulation that could jeopardize the stability of the mine. This multifaceted application makes it an indispensable asset in modern mining practices.

mining mesh

The evolution of mining mesh over the years has been influenced by technological advancements and the increasing demands of the mining industry. Traditional mining mesh consisted primarily of high-tensile steel, but recent innovations have introduced materials such as polymer and composite meshes, which offer enhanced durability and resistance to corrosion. Furthermore, advances in manufacturing techniques have allowed for the production of mesh that is lighter and easier to handle, which is crucial in the often cramped conditions of underground operations.

Safety standards and regulations in the mining industry have also driven improvements in mining mesh design and application. Regulatory bodies continually update guidelines to ensure that mining practices evolve alongside technological advances. This has led to the development of mesh products that can meet stringent safety standards while still being cost-effective for mining companies operating in a competitive environment.

As the mining industry continues to face challenges such as increasing operational costs and the need for sustainable practices, the role of mining mesh becomes even more critical. Its ability to enhance safety while improving efficiency makes it a vital element in the ongoing evolution of mining operations.

In conclusion, mining mesh is an essential component that underpins the safety and functionality of underground mining. As innovations continue to emerge, mining mesh will undoubtedly evolve further, reinforcing its status as a crucial element in the pursuit of safer and more efficient mining practices. By investing in advanced mesh technologies, the mining industry can ensure that it remains resilient in the face of evolving challenges.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025