-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

មករា . 31, 2025 03:32

Back to list

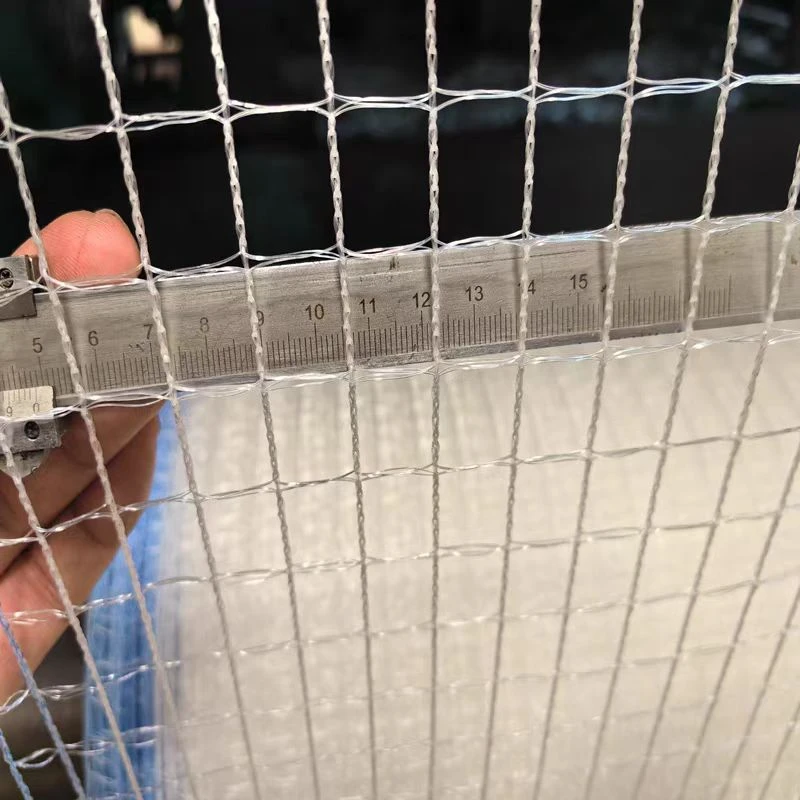

nylon insect mesh

Nylon mesh is a versatile and widely-used material, cherished across various industries for its unique blend of durability, flexibility, and usability. Those who are intimately familiar with this fabric understand its profound impact on both everyday applications and specialized industrial uses. Here's a deep dive into the remarkable world of nylon mesh, underscoring its unparalleled benefits and the reasons it stands out as the fabric of choice for many.

Moreover, nylon mesh supports an environmentally conscious choice for industries aiming to reduce their carbon footprint. As an eco-friendly material, it can be produced with lower environmental impact when compared to alternative materials. Major manufacturers are investing in sustainable production methods for nylon mesh, considering not only its biodegradability but also its ability to be recycled without significant degradation of quality. This shift towards sustainability underscores the industry’s commitment to authoritative practices in ecological responsibility. In terms of market expertise, the demand for nylon mesh is forecasted to rise, driven by innovations that continue to expand its applications across various sectors. This market trend is evident in the increasing number of patents filed for nylon mesh products, each presenting novel ways to harness its capabilities. Industry leaders remain at the forefront by developing new composites and blends that enhance nylon mesh's inherent qualities, catering to ever-evolving consumer needs. Quality assurance and expert knowledge ensure that the nylon mesh on the market today meets rigorous testing standards. This guarantees that consumers receive products that are reliable and trustworthy. The emphasis on quality control underscores the importance of manufacturing processes that comply with international standards, reassuring users of nylon mesh's safety and effectiveness. Professionals within the field appreciate the strategic advantage that nylon mesh provides. Its cost-effectiveness combined with its multi-functional applications make it a preferred choice for companies looking to maximize their return on investment. Suppliers offer extensive support and guidance, backed by years of experience, to assist businesses in selecting the right type of nylon mesh for their specific needs. This level of expertise enhances trust in the material, further cementing its authoritative status among textiles. In conclusion, the multifaceted utility and efficiency of nylon mesh make it a quintessential material in a variety of applications. Whether in sportswear, medical devices, filtration systems, or sustainable solutions, its prowess is well-documented and respected. Industry experts continue to explore and expand its potential, ensuring that nylon mesh remains an indispensable asset in modern material science, thus firmly establishing its standing as a credible and trustworthy resource.

Moreover, nylon mesh supports an environmentally conscious choice for industries aiming to reduce their carbon footprint. As an eco-friendly material, it can be produced with lower environmental impact when compared to alternative materials. Major manufacturers are investing in sustainable production methods for nylon mesh, considering not only its biodegradability but also its ability to be recycled without significant degradation of quality. This shift towards sustainability underscores the industry’s commitment to authoritative practices in ecological responsibility. In terms of market expertise, the demand for nylon mesh is forecasted to rise, driven by innovations that continue to expand its applications across various sectors. This market trend is evident in the increasing number of patents filed for nylon mesh products, each presenting novel ways to harness its capabilities. Industry leaders remain at the forefront by developing new composites and blends that enhance nylon mesh's inherent qualities, catering to ever-evolving consumer needs. Quality assurance and expert knowledge ensure that the nylon mesh on the market today meets rigorous testing standards. This guarantees that consumers receive products that are reliable and trustworthy. The emphasis on quality control underscores the importance of manufacturing processes that comply with international standards, reassuring users of nylon mesh's safety and effectiveness. Professionals within the field appreciate the strategic advantage that nylon mesh provides. Its cost-effectiveness combined with its multi-functional applications make it a preferred choice for companies looking to maximize their return on investment. Suppliers offer extensive support and guidance, backed by years of experience, to assist businesses in selecting the right type of nylon mesh for their specific needs. This level of expertise enhances trust in the material, further cementing its authoritative status among textiles. In conclusion, the multifaceted utility and efficiency of nylon mesh make it a quintessential material in a variety of applications. Whether in sportswear, medical devices, filtration systems, or sustainable solutions, its prowess is well-documented and respected. Industry experts continue to explore and expand its potential, ensuring that nylon mesh remains an indispensable asset in modern material science, thus firmly establishing its standing as a credible and trustworthy resource.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025