-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

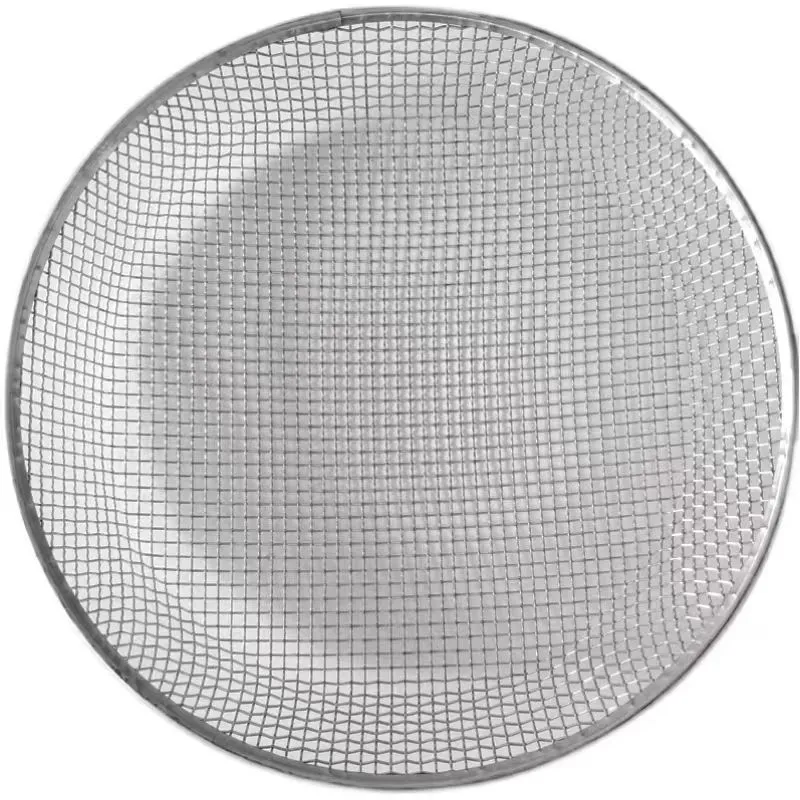

Steel Wire Mesh for Reinforcing Concrete Structures and Enhancing Durability and Strength

Steel Wire Mesh for Concrete Enhancing Structural Integrity

Steel wire mesh is a crucial reinforcement material used in concrete construction, enhancing the structural integrity and durability of concrete structures. It consists of a series of intersecting steel wires that form a grid-like pattern, which can be placed in slabs, walls, and other concrete elements. The primary purpose of steel wire mesh is to provide strength and resistance to tensile forces that concrete, on its own, cannot withstand.

The Importance of Reinforcement in Concrete

Concrete is a composite material known for its compressive strength. However, it is relatively weak in tension, making it prone to cracking under stress. This is where steel wire mesh comes into play. By integrating this mesh into concrete, engineers can create a composite material that benefits from the compressive strength of concrete and the tensile strength of steel. This combination significantly enhances the overall performance of the structure, allowing it to bear larger loads and resist various forms of stress, such as bending and shear forces.

Types of Steel Wire Mesh

There are several types of steel wire mesh available for concrete applications, including welded wire fabric and rebar meshes. Welded wire fabric is produced by welding cross wires to longitudinal wires at regular intervals, resulting in a strong and uniform grid. Rebar meshes, on the other hand, consist of individually placed rods that may or may not be tied together, depending on the specific engineering requirements.

The choice between these types depends on various factors, including the structural requirements, load conditions, and the nature of the concrete pour. For instance, welded wire fabric is commonly used in slabs for its ease of installation and ability to uniformly distribute loads, while rebar can be used for heavy-duty applications in foundations and retaining walls.

steel wire mesh for concrete

Installation Practices

Proper installation of steel wire mesh is critical to its performance. It is essential to position the mesh correctly within the concrete to ensure the effective transfer of loads. Typically, the mesh is placed at a distance from the bottom of the slab or wall, allowing the concrete to encase it fully. This positioning not only promotes good bond strength between the steel and concrete but also provides adequate cover to protect the steel from corrosion.

Moreover, during the installation process, it is vital to avoid any movement of the mesh as concrete is poured. If the mesh is displaced, it may lose its effectiveness, leading to potential structural weaknesses. Therefore, contractors often use chairs or supports to keep the mesh in place until the concrete is set.

Durability and longevity

One of the greatest advantages of using steel wire mesh in concrete is its contribution to the longevity of structures. By minimizing the occurrence of cracks and controlling their propagation, steel wire mesh extends the lifespan of concrete elements, reducing maintenance costs and the need for repairs. Additionally, in environments exposed to extreme weather conditions, corrosion-resistant wire mesh can provide even further durability and protection against rust, ensuring the integrity of the structure over time.

Conclusion

In summary, steel wire mesh is an indispensable component of modern concrete construction. It improves the tensile strength of concrete, enhances structural stability, and contributes to the overall durability of various elements in construction projects. By understanding the types of steel wire mesh available and proper installation practices, engineers and builders can ensure that their structures stand the test of time, offering safety and reliability for generations to come. As construction techniques evolve, the role of steel wire mesh will undoubtedly continue to be a foundational element in the pursuit of innovative, resilient structures.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025