-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Welded Screen Solutions for Durable Filtration and Security

The Strength and Versatility of Welded Screens

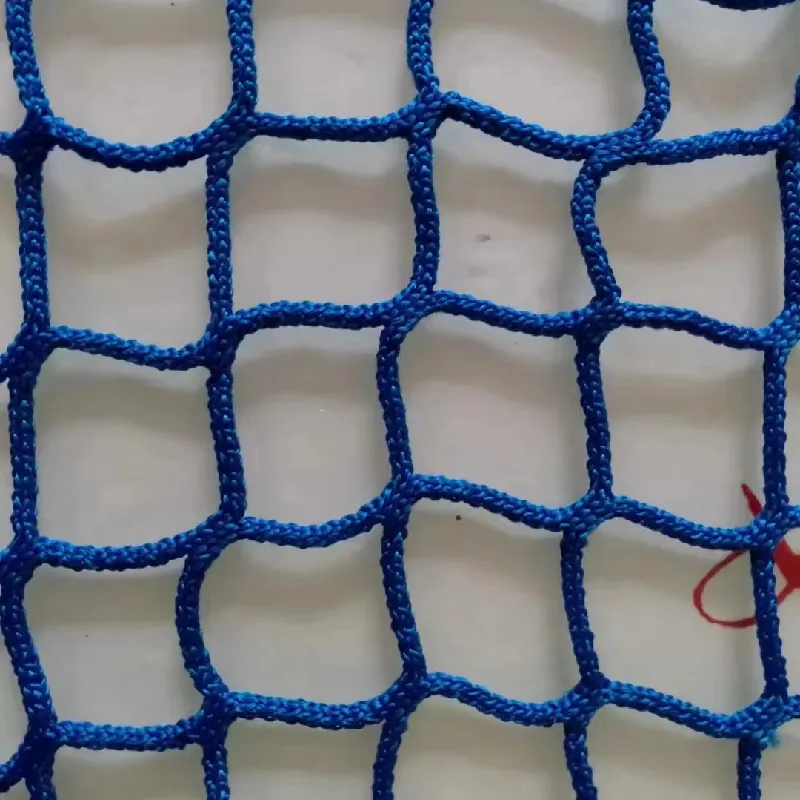

Welded screens, an essential component in various industries, have garnered attention for their strength, durability, and versatility. These screens are constructed from metal wires that are welded together at their intersections, creating a robust mesh. The manufacturing process ensures that the joints are strong enough to withstand tension and pressure, making welded screens ideal for numerous applications ranging from construction to agriculture.

One of the most prominent applications of welded screens is in the construction industry. Builders often utilize these screens as concrete reinforcement, providing enhanced structural integrity to cement structures. By embedding welded screens within concrete forms, the risk of cracking is significantly reduced. This application not only improves the longevity of buildings but also enhances safety for occupants.

In agriculture, welded screens play a vital role in protecting crops and livestock. Farmers use welded wire fencing to create secure enclosures that safeguard livestock from predators while allowing for proper ventilation and visibility. Additionally, welded screens are employed as protective barriers around gardens and orchards, preventing pests and larger animals from damaging plants. Their durability ensures that these barriers will withstand harsh weather conditions and remain effective for years.

Another key advantage of welded screens is their versatility in various filtration systems

. The precise openings in welded mesh can be tailored to specific needs, making them suitable for filtering out unwanted materials in water treatment facilities and industrial processes. Their robust construction allows them to handle high flow rates without compromising performance, ensuring efficient operations across different sectors.welded screen

In addition to their functional benefits, welded screens also come with aesthetic appeal. They are often used in architectural designs for projects ranging from residential properties to commercial buildings. The clean lines and uniform appearance of welded screens can complement modern design principles, while their structural integrity contributes to the overall stability and safety of constructions.

Maintenance of welded screens is relatively straightforward, making them a preferred choice for many industries. Routine inspections can help identify any signs of wear or damage, and if maintained properly, they can last for decades. Even in corrosive environments, specialized coatings can enhance the longevity of welded screens, ensuring their effectiveness over time.

Sustainability is another aspect that has led to the increasing popularity of welded screens. Many manufacturers are now focusing on producing these screens from recycled materials, which supports environmental initiatives while offering high-quality products. As industries move towards more sustainable practices, welded screens provide an eco-friendly solution without sacrificing performance.

In conclusion, welded screens are an indispensable tool across a multitude of sectors. Their strength, durability, and versatility make them ideal for applications in construction, agriculture, filtration systems, and architectural designs. As the demand for reliable and sustainable materials continues to grow, welded screens are poised to remain at the forefront, proving their worth in both functionality and design for years to come.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025