-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

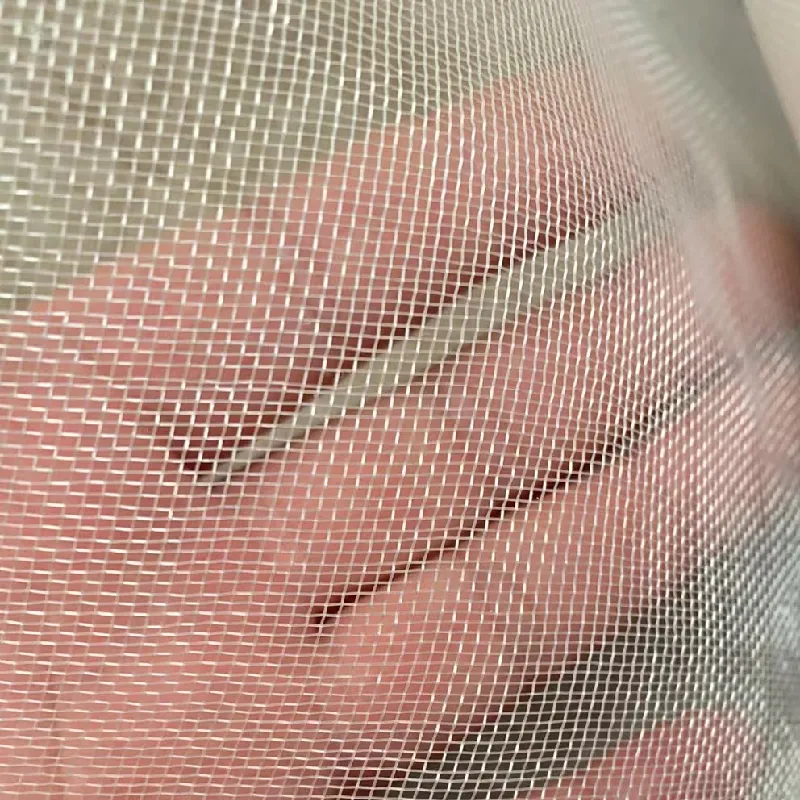

wire mesh filter

The Utility and Versatility of Wire Mesh Filters

Wire mesh filters are essential components in various industrial and domestic applications, known for their ability to separate solids from liquids and gases. Made from intertwined metal strands, these filters come in various mesh sizes and materials, catering to diverse filtering needs. This article explores the utility and versatility of wire mesh filters, highlighting their applications, benefits, and maintenance.

One of the primary uses of wire mesh filters is in the field of water treatment. They are employed in filtration systems to remove debris and particulates from water sources, ensuring that the water is clean and safe for consumption. By using wire mesh filters, municipalities can effectively reduce sediment and other contaminants, contributing to public health and environmental safety. Their durability and resistance to corrosion make them particularly suited for this purpose.

In industrial settings, wire mesh filters play a critical role in processes like oil and gas production, chemical processing, and food and beverage manufacturing. These filters help to maintain the quality of products by ensuring that unwanted particles are removed from the process streams. For instance, in the food industry, wire mesh filters are used to extract impurities from liquids like juices and oils, enhancing the product's quality and taste. The versatility of wire mesh filters allows them to be customized according to the specific requirements of each industry, such as varying mesh sizes for different filtration levels.

wire mesh filter

Additionally, wire mesh filters are increasingly utilized in HVAC systems to improve air quality. They are designed to trap dust, pollen, and other airborne particles, preventing them from circulating within indoor environments. This is especially important in commercial buildings and homes for maintaining a healthy atmosphere and preventing allergic reactions. With a proper maintenance schedule, wire mesh filters can significantly enhance the efficiency of HVAC systems while prolonging their lifespan.

Another advantageous feature of wire mesh filters is their ease of cleaning and maintenance. Unlike disposable filters that have to be replaced frequently, wire mesh filters can be easily cleaned and reused. This not only reduces waste but also lowers operating costs over time. Regular maintenance involves rinsing or washing the filters to remove accumulated debris, making them a sustainable option for filtration needs.

The adaptability of wire mesh filters extends to their design. They can be fabricated into various shapes and sizes to fit specific systems, from small-scale household filters to large industrial units. Advanced manufacturing techniques also allow for the combination of different mesh materials, enhancing their performance under various conditions. Whether it’s stainless steel for corrosion resistance or brass for strength, the choice of material can dramatically influence the filter's efficiency and lifespan.

In conclusion, wire mesh filters are indispensable tools used across a plethora of applications. Their ability to effectively separate solids from liquids and gases, combined with their durability and ease of maintenance, makes them an ideal choice for industries ranging from water treatment to food processing, and HVAC systems. As technology advances, the designs and applications of wire mesh filters are likely to expand, further solidifying their role in ensuring product quality, efficiency, and sustainability in various sectors.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025