-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

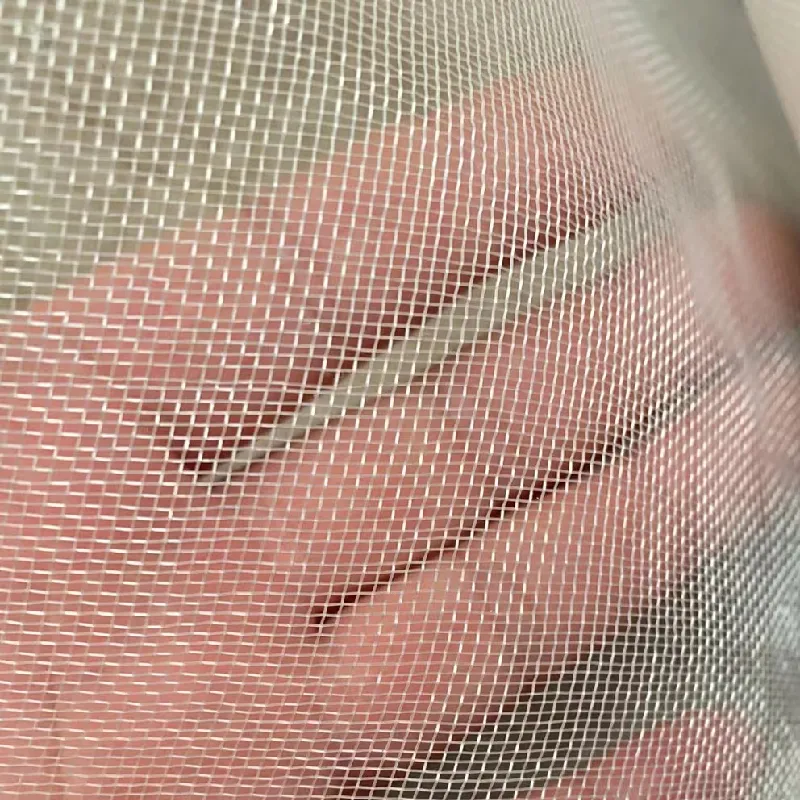

wire mesh manufacturing machine

The Evolution and Importance of Wire Mesh Manufacturing Machines

Wire mesh is an essential material used in various industries, from construction and agriculture to filtration and security. The evolution of wire mesh manufacturing machines has played a significant role in enhancing production efficiency and quality. These machines not only streamline the manufacturing process but also ensure that the resulting products meet the diverse needs of the market.

Wire mesh manufacturing machines come in various types, each tailored for specific tasks in the production process. The most common machines include wire drawing machines, weaving machines, and welding machines. Wire drawing machines are crucial for reducing the diameter of wire through a series of dies, allowing manufacturers to achieve the desired tensile strength and thickness. These machines are designed to operate quickly and efficiently, enabling large volumes of wire to be produced in a short timeframe.

Weaving machines, on the other hand, are essential for creating intricate mesh patterns. Historically, weaving was a manual process, requiring skilled artisans to interlace wires. However, modern weaving machines have significantly automated this process, allowing for higher precision and consistency. These machines can produce various types of wire mesh, including plain weave, twill weave, and specialty meshes, catering to different industrial applications.

wire mesh manufacturing machine

Another important type of machine is the wire mesh welding machine. These machines are used to create welded wire mesh panels, commonly used in construction for reinforcement and in fencing applications. Automated welding machines have revolutionized this aspect of production, allowing for faster and more robust construction of wire mesh products. They can seamlessly integrate with other manufacturing systems, ensuring that production lines operate smoothly and with minimal downtime.

The advancements in technology have led to the development of computer-controlled wire mesh manufacturing machines. These machines enhance precision and allow for easier adjustments during the production process. Users can input specifications directly into the machine, which then optimizes the production parameters accordingly. This capability not only improves the quality of the wire mesh but also reduces waste and lowers production costs.

Moreover, as sustainability becomes a principal concern for manufacturers, modern wire mesh machines are designed with energy efficiency in mind. They can operate on lower power levels while still delivering high-quality outputs. This shift towards more sustainable production methods is essential in meeting both regulatory standards and consumer expectations.

In conclusion, wire mesh manufacturing machines have transformed the production landscape, driving innovation and efficiency across various industries. As technology continues to evolve, we can expect further advancements in these machines, leading to even higher quality products and more sustainable practices. Whether in construction, agriculture, or security, the impact of these machines will be felt for years to come, making them a pivotal component in the supply chain of wire mesh products.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025