-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

شوبات . 08, 2025 00:39

Back to list

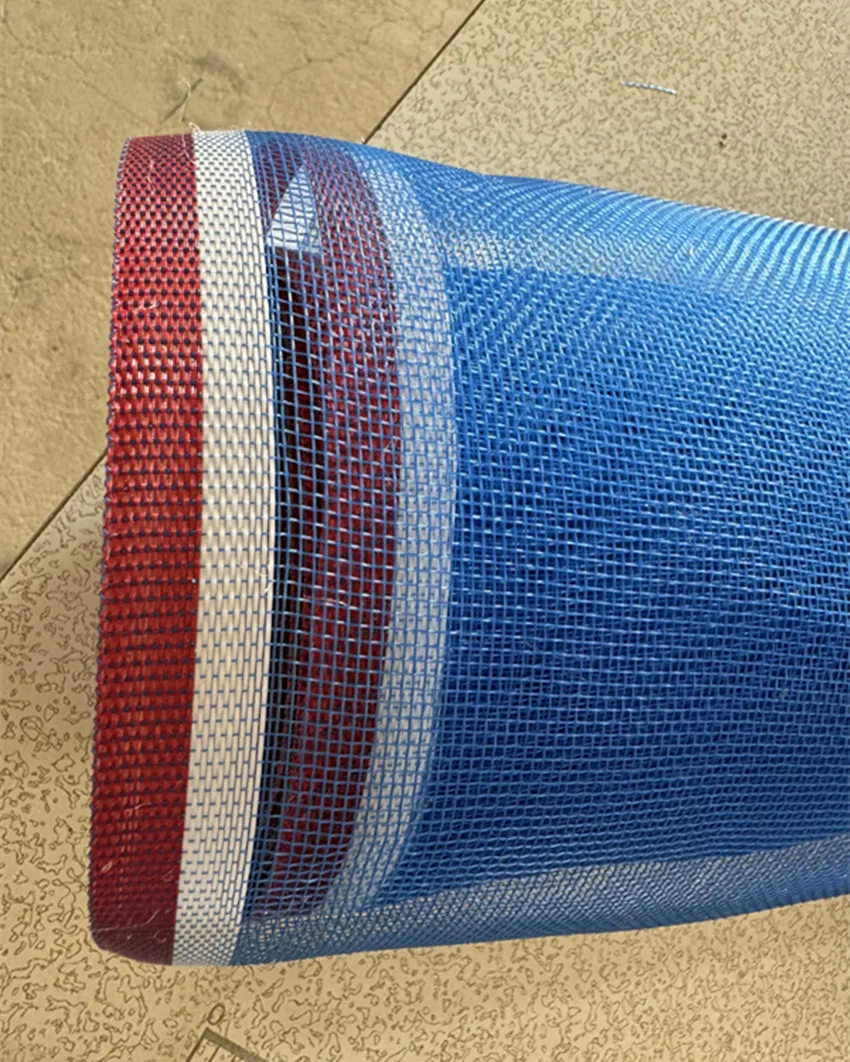

hard plastic mesh

Navigating the world of innovative materials, hard plastic mesh emerges as a versatile solution with wide-ranging applications across industries. This seemingly simple product has revolutionized how we approach tasks in sectors such as agriculture, construction, and manufacturing. Underpinning its value is a blend of durability, adaptability, and long-term cost-effectiveness, making it an indispensable tool in modern projects.

Manufacturing industries capitalize on the customization offered by plastic meshes. Available in diverse sizes and densities, companies can tailor these meshes to meet specific operational needs, be it as protective machine guards, light filtration systems, or even as packaging material that ensures product safety without adding excessive weight. The adaptability of hard plastic mesh in manufacturing processes underscores its role in advancing operational precision and reducing waste through optimized resource use. Emphasizing its environmental impact, hard plastic mesh aligns with sustainability goals as enterprises shift focus towards eco-friendly solutions. Many manufacturers are exploring the use of recycled materials in the production of these meshes, thereby reducing the plastic footprint and promoting a circular economy. This alignment with green initiatives not only enhances a company's corporate responsibility image but also appeals to a growing market of environmentally conscious consumers. However, the implementation of hard plastic mesh is not devoid of challenges. It necessitates a keen understanding of application specifics and mesh properties to maximize effectiveness. Buyers must pay attention to mesh thickness and pattern to ensure it meets their particular needs without compromising performance. As industry experts emphasize, collaborating with experienced suppliers who can offer guidance and support throughout the selection and implementation stages is crucial. In conclusion, hard plastic mesh stands as a testament to the blend of functionality and innovation in material technology. It not only addresses immediate application needs across various sectors but also offers a sustainable, long-term solution. By investing in hard plastic mesh, industries can achieve enhanced efficiency, reduced costs, and a commitment to eco-friendly practices, ultimately driving progress in a competitive global landscape.

Manufacturing industries capitalize on the customization offered by plastic meshes. Available in diverse sizes and densities, companies can tailor these meshes to meet specific operational needs, be it as protective machine guards, light filtration systems, or even as packaging material that ensures product safety without adding excessive weight. The adaptability of hard plastic mesh in manufacturing processes underscores its role in advancing operational precision and reducing waste through optimized resource use. Emphasizing its environmental impact, hard plastic mesh aligns with sustainability goals as enterprises shift focus towards eco-friendly solutions. Many manufacturers are exploring the use of recycled materials in the production of these meshes, thereby reducing the plastic footprint and promoting a circular economy. This alignment with green initiatives not only enhances a company's corporate responsibility image but also appeals to a growing market of environmentally conscious consumers. However, the implementation of hard plastic mesh is not devoid of challenges. It necessitates a keen understanding of application specifics and mesh properties to maximize effectiveness. Buyers must pay attention to mesh thickness and pattern to ensure it meets their particular needs without compromising performance. As industry experts emphasize, collaborating with experienced suppliers who can offer guidance and support throughout the selection and implementation stages is crucial. In conclusion, hard plastic mesh stands as a testament to the blend of functionality and innovation in material technology. It not only addresses immediate application needs across various sectors but also offers a sustainable, long-term solution. By investing in hard plastic mesh, industries can achieve enhanced efficiency, reduced costs, and a commitment to eco-friendly practices, ultimately driving progress in a competitive global landscape.

Next:

Latest news

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025