-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Effective Use of Plastic Mesh for Optimizing Plastering Techniques and Enhancing Wall Stability

The Advantages of Plastic Mesh for Plastering

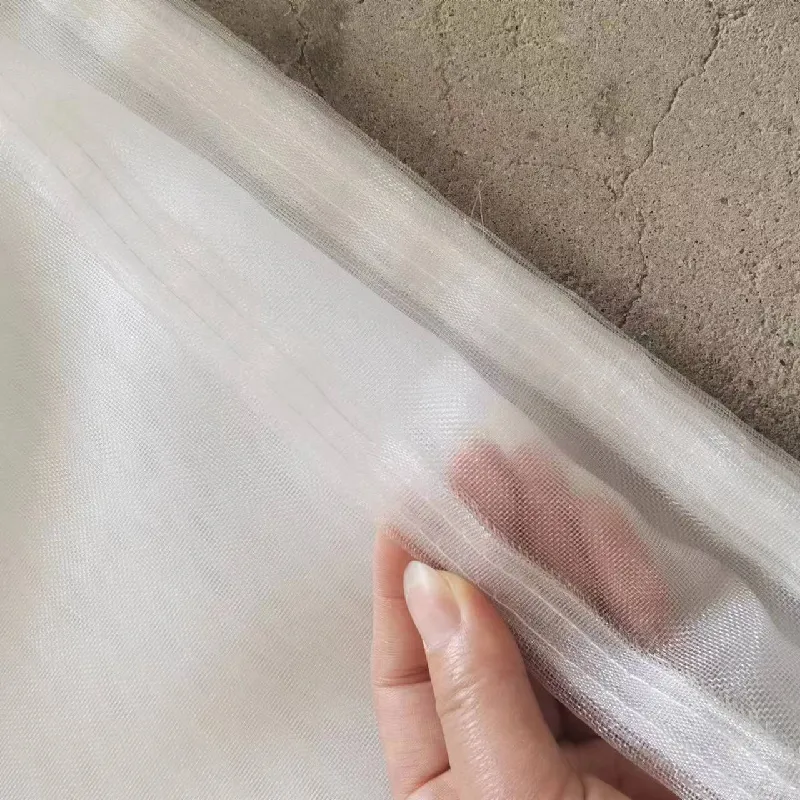

In the world of construction and renovation, achieving a smooth and durable finish is crucial. When it comes to plastering, using the right materials can make a significant difference in the final outcome. One such material that has gained popularity in recent years is plastic mesh. This innovative product offers a range of advantages that make it an ideal choice for plastering applications.

Plastic mesh, typically made from high-density polyethylene (HDPE) or polypropylene, is designed to reinforce the plastering process. It provides a stable foundation for the plaster, preventing cracking and improving the overall strength of the wall. Unlike traditional metal lath, plastic mesh is lightweight and flexible, making it easier to handle and install. This ease of use is especially beneficial for DIY enthusiasts and small contractors who may not have access to heavy machinery.

The Advantages of Plastic Mesh for Plastering

Moreover, plastic mesh promotes better adhesion of the plaster to the underlying surface. The mesh creates an effective bonding surface, allowing the plaster to grip securely. This is crucial for preventing delamination, where the plaster may separate from the wall over time. As a result, using plastic mesh can lead to longer-lasting plaster applications, reducing the need for frequent repairs and maintenance.

plastic mesh for plastering

Another advantage of plastic mesh is its versatility. It can be used on a variety of surfaces, including drywall, concrete, and masonry. This adaptability makes it suitable for a wide range of projects, from small repairs to large-scale renovations. Additionally, plastic mesh comes in various sizes and thicknesses, allowing builders to select the most appropriate option for their specific needs.

Environmental considerations are also important in today's construction industry. Plastic mesh is often made from recycled materials, making it a more sustainable choice compared to traditional metal lath. As builders and homeowners become increasingly conscious of their environmental impact, opting for plastic mesh can contribute to greener construction practices.

Furthermore, the installation process for plastic mesh is straightforward. It can be easily cut to size with standard tools, allowing for quick adjustments on-site. This simplicity can save both time and labor costs during the plastering process. After installation, plaster can be applied directly over the mesh, creating a seamless and professional-looking finish.

In conclusion, plastic mesh has emerged as a superior alternative to traditional materials for plastering applications. Its lightweight nature, resistance to corrosion, and compatibility with a variety of surfaces make it an ideal choice for both contractors and DIY projects. With its ability to enhance adhesion, promote durability, and contribute to sustainable building practices, plastic mesh is revolutionizing the plastering industry. As more professionals recognize its benefits, it is likely to become a standard material in plastering projects across the globe. Using plastic mesh not only improves the quality of plaster finishes but also offers peace of mind for builders and homeowners alike, knowing they made a smart choice for their construction needs.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025