-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

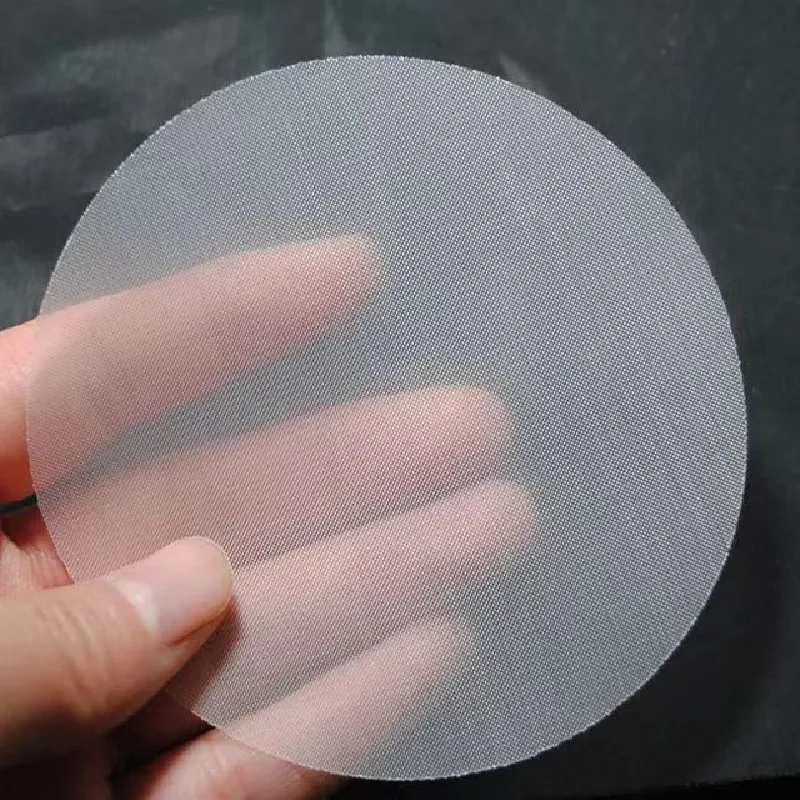

Durable Steel Wire Mesh for Enhanced Filtration and Industrial Applications

The Versatility and Importance of Steel Wire Screens

Steel wire screens have emerged as one of the most essential tools in a variety of industries, thanks to their strength, durability, and versatility. Used in applications ranging from construction and mining to agriculture and food processing, these screens play a critical role in filtration, separation, and protection. This article will explore the features, applications, and benefits of steel wire screens, highlighting their significance in modern industry.

What Are Steel Wire Screens?

Steel wire screens are made from high-quality steel wires that are woven together to create a mesh with defined openings. The size and shape of these openings can vary widely, depending on the intended use of the screen. This adaptability allows manufacturers to produce screens tailored to specific requirements, whether for sieving gravel in a construction site or filtering liquids in a food processing facility.

The strength of the steel used in these screens ensures they can withstand significant mechanical stress, making them ideal for environments subject to heavy wear and tear. Additionally, steel wire screens can be galvanized or coated to provide enhanced corrosion resistance, further extending their lifespan and suitability for outdoor and industrial applications.

Applications of Steel Wire Screens

1. Construction In the construction industry, steel wire screens are essential for separating materials such as sand, gravel, and soil. They are often used in concrete production to ensure a consistent mix by removing larger aggregates and debris. Further, during concrete pouring and finishing, these screens help minimize the chances of uneven curing by allowing excess water and small particles to drain away.

2. Mining and Mineral Processing Steel wire screens are crucial in mining operations, where they facilitate the separation of minerals from ore. These screens are employed in various stages of mineral processing, including dry screening and wet washing, to ensure high efficiency and quality in mineral extraction.

3. Agriculture Farmers utilize steel wire screens for sorting seeds, grains, and livestock feed. The ability to customize mesh sizes allows for efficient separation, ensuring the delivery of quality products. Additionally, in irrigation systems, screens prevent the clogging of filters and pumps by capturing debris from water sources.

steel wire screen

4. Food Processing In the food and beverage industry, hygiene and safety are paramount. Steel wire screens are employed in various processes such as filtering and sifting to ensure that contaminants and unwanted materials are removed. These screens can be easily cleaned and sanitized, making them suitable for food production.

5. Environmental Applications Steel wire screens are also utilized in wastewater treatment and filtration systems. They play a vital role in removing solid waste and contaminants from water, contributing to cleaner environments and sustainable practices.

Advantages of Steel Wire Screens

- Durability Steel wire screens are highly resistant to wear, tear, and corrosion, making them suitable for both indoor and outdoor applications. Their robust construction allows them to withstand harsh conditions, providing long-lasting service.

- Versatility One of the strongest features of steel wire screens is their adaptability. With various mesh sizes and configurations, these screens can cater to numerous industrial requirements.

- Cost-Effectiveness Although the initial investment may be higher than that of non-metallic alternatives, the durability and longevity of steel wire screens often translate to lower maintenance costs and longer service life, making them an economical choice in the long run.

- Efficiency Steel wire screens enable efficient separation and filtering, minimizing downtime and ensuring optimal performance in industrial processes. Their structural integrity ensures that they maintain their shape and functionality under continuous operation.

Conclusion

Steel wire screens are an invaluable asset across multiple industries due to their durability, versatility, and cost-effectiveness. From construction sites to food processing facilities, these screens ensure efficiency and safety in various applications. As industries continue to evolve and seek reliable solutions for material separation and filtration, the importance of steel wire screens will undoubtedly grow, reinforcing their place as a vital component in modern industrial practices.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025