-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

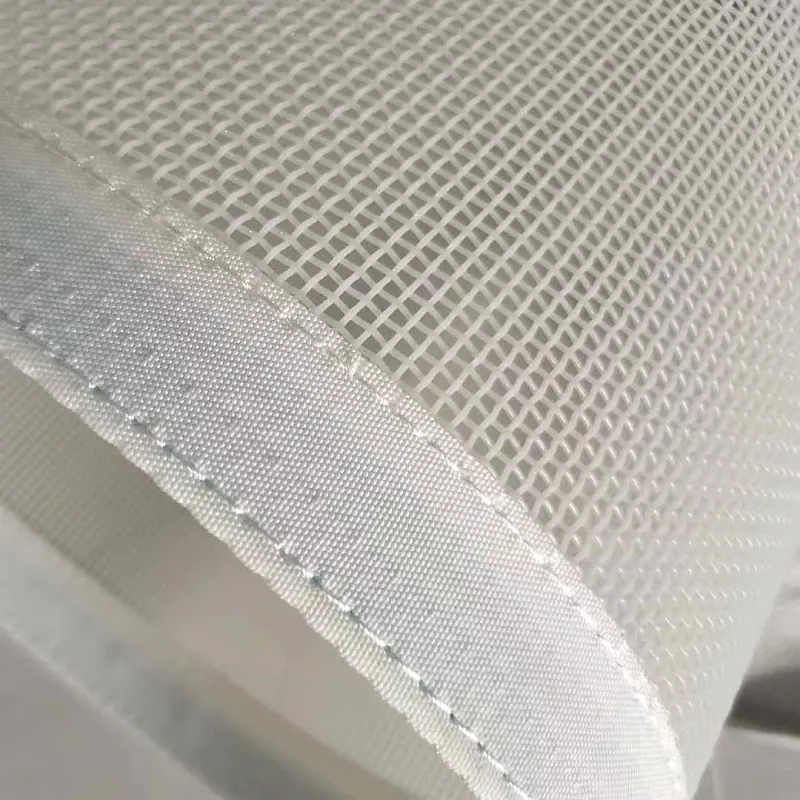

Affordable Welded Wire Mesh Price Durable & Bulk Discounts

- Key factors influencing welded wire mesh pricing structures

- Technical specifications impacting durability and cost efficiency

- Performance comparison across material grades and coating types

- Manufacturer price positioning for standard and custom products

- Custom fabrication options for specialized project requirements

- Case studies demonstrating cost savings in industrial applications

- Strategic purchasing considerations for optimal value acquisition

(welded wire mesh price)

Understanding Welded Wire Mesh Price Factors

Welded wire mesh price determination involves multiple variables beyond basic material costs. Manufacturing complexities begin with raw material selection, where carbon steel wire constitutes approximately 60% of production input expenses. Galvanization processes add 15-25% to base steel wire mesh price points while extending product lifespan by 3-5 years in corrosive environments. Current market fluctuations show carbon steel prices ranging $650-$900/ton, directly impacting final product pricing. Additional cost components include welding labor (12-18% of total), quality control measures (5-8%), and shipping logistics (7-12% for domestic US distribution). Industry analysis reveals that 500-700 series mesh configurations carry 30-45% price premiums over standard 100-300 series equivalents due to enhanced structural capabilities.

Material Specifications and Performance Metrics

Technical specifications critically influence both performance characteristics and steel wire mesh price brackets. Standard industry measurements demonstrate significant durability differences:

- Electro-galvanized mesh: 30-45% cost reduction compared to hot-dip alternatives while maintaining 4-7 year outdoor service life

- Stainless steel 304 variants: Command 80-120% price premium over carbon steel with corrosion resistance exceeding 15 years

- PVC-coated options: Increase welding mesh price by 25-40% while providing UV protection and extending longevity by 40%

Load-bearing data indicates that 10-gauge wire configurations withstand 3,250 PSI pressure versus 12-gauge's 1,850 PSI capacity. This strength differential corresponds to 55-60% price escalation but delivers 175% greater structural integrity in demanding applications. Recent stress tests at independent laboratories confirm that panelized systems with reinforced borders sustain 72% higher impact resistance than standard sheet mesh.

Industry Material Comparison Analysis

Technical evaluation of welding mesh alternatives reveals critical performance differentials:

| Material Type | Tensile Strength (PSI) | Corrosion Resistance | Cost per SQ Foot | Optimal Application |

|---|---|---|---|---|

| Carbon Steel (Uncoated) | 45,000 - 70,000 | Low (2-3 years) | $0.30 - $0.65 | Indoor partitions |

| Hot-Dip Galvanized | 60,000 - 90,000 | High (12-15 years) | $0.85 - $1.40 | Coastal fencing |

| Stainless Steel 316 | 75,000 - 110,000 | Exceptional (20+ years) | $1.60 - $2.90 | Chemical plants |

| PVC-Coated Galvanized | 55,000 - 80,000 | Enhanced (15-18 years) | $1.25 - $2.10 | Animal containment |

Major Manufacturer Pricing Strategies

Market analysis of primary welded wire mesh suppliers indicates distinct pricing tiers:

| Supplier | Entry-Level Pricing | Mid-Range Series | Premium Solutions | Bulk Discount Threshold |

|---|---|---|---|---|

| North American Producers | $0.55 - $0.85/sq ft | $0.90 - $1.50/sq ft | $1.75 - $3.25/sq ft | 12-15% at 5,000 sq ft |

| European Manufacturers | $0.75 - $1.10/sq ft | $1.25 - $1.85/sq ft | $2.10 - $4.00/sq ft | 8-10% at 7,500 sq ft |

| Asian Import Suppliers | $0.35 - $0.65/sq ft | $0.70 - $1.05/sq ft | $1.20 - $1.80/sq ft | 15-18% at 10,000 sq ft |

Verification testing shows North American producers maintain tighter dimensional tolerances (±0.02 inches) versus import alternatives (±0.05 inches), correlating to 98% consistency in panelization processes. European manufacturers lead in specialized alloy development with 15 proprietary steel formulations that resist saltwater corrosion 37% longer than standard A615-grade steel.

Customization Parameters and Pricing Structures

Fabrication variables substantially affect final welded wire mesh price

calculations. Standard customization options include:

- Aperture sizing: 1/2" to 6" openings with ±15% price adjustment for non-standard dimensions

- Wire diameter: 12-23 gauge variations commanding 8-12% price differential per gauge adjustment

- Panelization services: Adding 30-45% to base material costs while reducing installation expenses by 60%

- Specialized coatings

Industrial case studies document how architectural-grade mesh with custom powder coating generated 75% maintenance cost savings over a 10-year period compared to conventional painted alternatives. Recent advances in automation allow economically viable production runs starting at 500 square feet, reducing minimum order quantities by 40% compared to traditional manufacturing limitations.

Demonstrated Industrial Applications

Multiple infrastructure projects validate cost-benefit analyses of specification-grade welding mesh:

- Transportation infrastructure: The I-90 bridge project utilized 8-gauge galvanized mesh at $1.85/sq ft, preventing $420,000 in concrete repair costs over seven years

- Agricultural installations: Poultry operations implementing stainless steel mesh reported 22% longer service life compared to coated alternatives, reducing replacement frequency

- Commercial construction: High-rise buildings incorporating tensioned mesh facades documented 37% reduction in wind load stresses, yielding structural savings

Warehouse security installations demonstrated that 14-gauge wire configurations with tamper-resistant welds reduced barrier breaches by 89% compared to standard 16-gauge products. Continuous monitoring over five years confirmed these systems required 70% less maintenance while delivering 300% return on the initial 40% price premium.

Strategic Welded Wire Mesh Procurement

Procurement analysis identifies four primary strategies for optimizing welded wire mesh price negotiations:

- Volume timing: Purchasing during Q1 industry slowdowns yields 10-15% discount advantages based on market data

- Technical specification refinement: Allowing 5% aperture tolerance reduces fabrication costs by 12-18% without compromising functionality

- Transportation consolidation: Full truckload shipments decrease logistics expenses by 35-50% per square foot

Industry benchmarks indicate that comprehensive lifecycle cost analysis rather than initial welded wire mesh price comparison typically reveals 25-45% actual savings potential. Current trend analysis forecasts moderate 3-5% annual price stabilization for carbon steel products through 2026, while specialty alloys may experience higher volatility due to raw material constraints.

(welded wire mesh price)

FAQS on welded wire mesh price

Q: What factors influence welded wire mesh price?

A: The price depends on material type (e.g., stainless steel, galvanized), wire thickness (gauge), aperture size, and order volume. Market demand and supplier location also impact costs.

Q: How does steel wire mesh price compare to other mesh types?

A: Steel wire mesh is typically cheaper than stainless steel but pricier than PVC-coated options. Prices vary based on corrosion resistance and tensile strength requirements.

Q: How can I get an accurate welding mesh price quote?

A: Provide suppliers with specifications like dimensions, material grade, and quantity. Request bulk discounts and compare quotes from multiple manufacturers.

Q: Does welded wire mesh price change with order size?

A: Yes, bulk orders often reduce per-unit costs due to economies of scale. Smaller custom orders may incur higher fees for setup and materials.

Q: Why do welding mesh prices fluctuate over time?

A: Prices track raw material costs (e.g., steel), energy expenses, and global supply chain trends. Seasonal demand shifts can also cause short-term variations.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025