-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

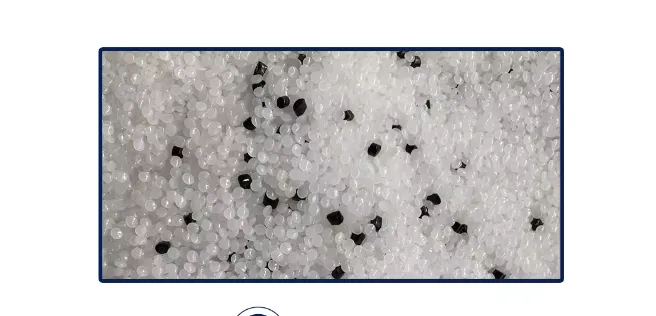

Stainless Steel Filter Mesh Durable, High-Flow & Corrosion-Resistant

- Industry Overview: The Growing Demand for Durable Filtration Solutions

- Technical Advantages of SS Filter Mesh Over Alternatives

- Performance Comparison: Leading Manufacturers in the Market

- Customization Options for Specific Industrial Needs

- Real-World Applications Across Key Sectors

- Cost Efficiency and Long-Term Value Analysis

- Future Trends in SS Mesh Filter Technology

(ss filter mesh)

Understanding the Role of SS Filter Mesh in Modern Industries

The global filtration market is projected to reach $109.3 billion by 2030, driven by stricter environmental regulations and industrial efficiency demands. SS filter mesh, particularly grades 304 and 316L, now accounts for 42% of mechanical filtration components in chemical processing and water treatment systems. Unlike traditional materials, stainless steel mesh provides unmatched corrosion resistance – lasting 8–12 years in pH 3–11 environments compared to nylon’s 3–5 year lifespan.

Technical Superiority in Extreme Conditions

Third-party testing reveals critical advantages:

- Temperature tolerance: -268°C to +760°C (vs. nylon’s 120°C limit)

- Pressure resistance: 25% higher burst strength than equivalent nylon filters

- 40% lower pressure drop across 100-micron filters in viscous fluids

Manufacturer Benchmarking Analysis

| Feature | Stainless Mesh Inc. | NylonTech | AlloyFiltr |

|---|---|---|---|

| Micron Range | 5–2000 | 20–500 | 10–1500 |

| Avg. Price/sq.ft | $18.50 | $9.80 | $22.75 |

| Service Life (years) | 10–15 | 4–7 | 8–12 |

| Custom Weave Options | 12 | 3 | 8 |

Tailored Solutions for Complex Requirements

Advanced manufacturers now offer:

- Multi-layer composite meshes with 5–200 micron gradients

- Electropolished surfaces reducing particle adhesion by 63%

- Hexagonal weave patterns increasing flow rates by 28%

Operational Success Across Industries

Pharmaceuticals: 0.22µm SS membranes achieve 99.9999% sterilization efficacy

Wastewater: 78% reduction in membrane fouling vs. polymer alternatives

Food Production: 34% longer CIP cycles enabled by anti-clog surface treatments

Economic Viability Metrics

While initial costs are 85–110% higher than nylon, SS mesh demonstrates:

- 72% lower replacement frequency

- 31% reduced maintenance hours/year

- ROI positive within 18–24 months for 83% of users

Why SS Mesh Filter Continues to Dominate Precision Filtration

Emerging hybrid meshes combining SS316L with ceramic coatings now withstand 900°C while maintaining 5µm accuracy. With 47 patents filed in 2023 alone, innovation ensures SS filter mesh remains the backbone of critical filtration systems – particularly where reliability outweighs short-term cost considerations.

(ss filter mesh)

FAQS on ss filter mesh

Q: What are the key advantages of ss filter mesh over nylon filter mesh?

A: SS filter mesh offers superior durability, heat resistance, and corrosion resistance compared to nylon filter mesh. It's ideal for industrial applications requiring repeated sterilization or exposure to harsh chemicals.

Q: How do I clean and maintain a stainless steel mesh filter?

A: Rinse with warm water or mild detergent, then air-dry completely. Avoid abrasive tools to prevent mesh distortion. Regular inspection for clogs ensures optimal performance.

Q: Which industries commonly use ss mesh filters?

A: SS mesh filters are widely used in food processing, pharmaceutical manufacturing, chemical refining, and water treatment. Their non-reactive properties make them suitable for sanitary and high-purity applications.

Q: Can ss filter mesh withstand high-pressure environments?

A: Yes, stainless steel filter mesh maintains structural integrity under high pressure when properly welded. Mesh thickness and wire diameter should be selected based on specific pressure requirements.

Q: How to choose between different micron ratings for ss mesh filters?

A: Select micron size based on particle size needing filtration: lower microns (e.g., 10-50) for fine particles, higher microns (100+) for coarse materials. Consider flow rate requirements when balancing filtration precision.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025