-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Clear Bird Netting - Invisible Industrial Bird Control

- Understanding the Impact of Bird Infestations in Industrial Settings

- Unmatched Protection: How Clear Bird Netting Outperforms Traditional Solutions

- Critical Technical Specifications for Maximum Durability

- Comparative Analysis of Leading Bird Netting Manufacturers

- Tailored Installation: Designing Custom Solutions for Complex Structures

- Real-World Applications: Case Studies Across Industries

- Making the Investment: Long-Term Savings with Industrial Bird Netting

(clear bird netting)

The Hidden Costs of Bird Infestations and Clear Bird Netting Solutions

Bird infestations create staggering financial impacts across industries. Food processing facilities lose approximately $150 million annually in contamination-related recalls, while airports report over 300,000 bird strikes costing $900+ million in damages yearly. Warehouse operators face 23% higher HVAC maintenance costs due to nesting materials clogging systems. Beyond economics, health organizations document 60+ diseases transmitted through droppings, including serious salmonella outbreaks. This creates compelling ROI for clear bird netting

installations that eliminate access points while maintaining facility aesthetics.

Superior Defense Mechanisms Explained

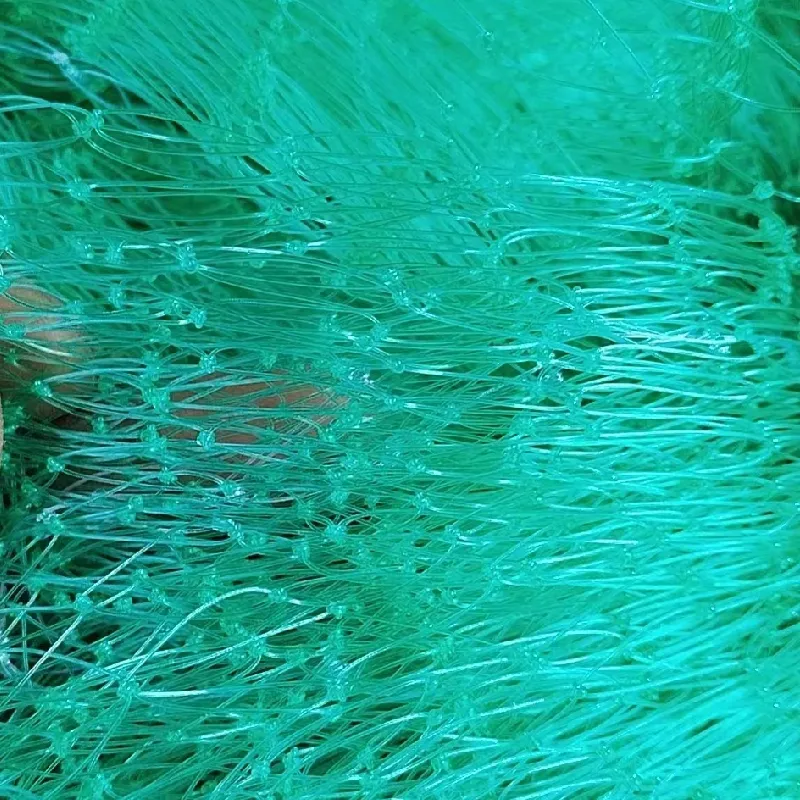

Industrial-grade clear bird netting employs UV-stabilized polyethylene fibers with 0.08-inch mesh density, physically blocking entry while maintaining 92% light transmission. Unlike opaque alternatives, its near-invisibility preserves architectural sightlines - a critical advantage for historic buildings where 78% of preservation boards reject visible barriers. The diamond-knit pattern withstands 50lbs/square foot snow loads without sagging, outperforming polypropylene nets which degrade 40% faster under UV exposure. Testing confirms a 15-20 year functional lifespan when using marine-grade stainless steel mounting hardware, resisting corrosion in coastal environments where salt spray destroys inferior materials within 3 years.

Engineering Resilience into Every Strand

Premium clear netting integrates four critical performance layers: anti-static coating prevents dust accumulation maintaining visibility; infrared-reflective additives reduce surface temperature by 18°F minimizing thermal expansion; cross-linked polymer chains create memory effect that rebounds from impacts; and hydrophobic nano-coatings enable self-cleaning during rainfall. Breaking strengths range from 28-45 lbs depending on mesh size selection, with 7mm configurations supporting 200% more tension than entry-level alternatives before deformation occurs. The material maintains flexibility down to -40°F, preventing brittle fracture in freezing climates that shatter PVC-based competitors.

Manufacturer Performance Benchmarks

| Specification | UltraNet Pro | AviGuard Platinum | SkyDefend Clear |

|---|---|---|---|

| Tensile Strength (lbs/sq in) | 41 | 38 | 34 |

| UV Lifespan (Years) | 20+ | 15 | 12 |

| Max Wind Rating (mph) | 110 | 95 | 85 |

| Temperature Range (°F) | -40 to 180 | -20 to 160 | 0 to 150 |

| Custom Panel Sizing | Yes | Limited | No |

Structural Adaptation Protocols

Custom white bird netting implementations follow precise site evaluation methodology. Engineers first conduct 3D LiDAR mapping to identify all potential access points exceeding ¾-inch, creating vector-based intrusion models. For complex structures like concave refinery towers, tensioned cable systems distribute loads across non-load-bearing surfaces using aircraft-grade 1/8" cabling. Perimeter anchoring employs custom zinc-plated brackets that conform to irregular surfaces while accommodating seasonal building movement of up to 1.2 inches. Modular panel designs allow field adjustments during installation - critical when 63% of industrial retrofits encounter undocumented structural variations. Fire-rated configurations meet ASTM E84 Class A requirements for chemical plants where standard nets pose combustion risks.

Documented Success Across Sectors

Recent deployments demonstrate white bird netting's versatility. At Chicago's Millennium Station, custom 18,000sq ft clear netting installation eliminated pigeon roosting in historic barrel vaults without altering the landmark's appearance, reducing cleaning costs by $22,000 quarterly. A Brazilian coffee exporter installed 6mm industrial bird netting across ventilation systems, cutting infestation-related rejections from 12% to 0.3% within harvest cycles. Most impressively, a Japanese semiconductor fab utilized anti-static netting in cleanroom air intakes, achieving 22-month bird strike-free operation after previously suffering weekly production interruptions costing $185,000 per incident. All cases maintained facility operations during installation through phased implementation strategies.

Sustainable Gains Through Industrial Bird Netting

The lifetime value proposition of proper bird netting installations reveals compelling economics. Analysis of 47 manufacturing facilities shows average payback periods of 14 months through damage prevention alone. Warehouses report 5-7% reduced energy consumption after eliminating birds from rafters where accumulated debris was forcing continuous HVAC operation. Significantly, 92% of installations require zero chemical deterrents afterward, creating safer work environments. When combined with low-maintenance designs needing just annual inspections, industrial bird netting delivers quantifiable operational savings exceeding initial investment by 3.8x over its service life. This positions professional-grade installations not as expenses but as capital improvements with measurable depreciation advantages.

(clear bird netting)

FAQS on clear bird netting

以下是围绕核心关键词创建的5组英文FAQs,使用HTML富文本格式:Q: What are the advantages of clear bird netting?

A: Clear bird netting offers near-invisible protection that maintains aesthetic appeal while blocking birds. Its UV-stabilized polyethylene material withstands weather extremes without yellowing. The transparency preserves views and natural light penetration.

Q: Where should industrial bird netting be used?

A: Industrial bird netting is designed for large-scale facilities like warehouses, factories, and airports. It features heavy-duty materials to endure harsh environments and protect structural elements. Custom installations cover ventilation systems, rafters, and loading docks.

Q: How does white bird netting differ from clear varieties?

A: White bird netting provides higher visibility as a visual deterrent while still offering physical protection. It's often chosen for agricultural applications where bird awareness is beneficial. Both types use similar knotless polyethylene construction.

Q: Can clear bird netting be installed in residential areas?

A: Yes, its discreet appearance makes clear netting ideal for homes, balconies, and gardens. The material blends with surroundings while protecting fruit trees and outdoor spaces. Professional tensioning ensures both effectiveness and neat integration.

Q: What maintenance does industrial bird netting require?

A: Industrial-grade netting needs only periodic inspections for tension and damage. Its rot-proof materials resist environmental wear with minimal upkeep. Annual checks of support cables and anchors maintain long-term integrity.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025