-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

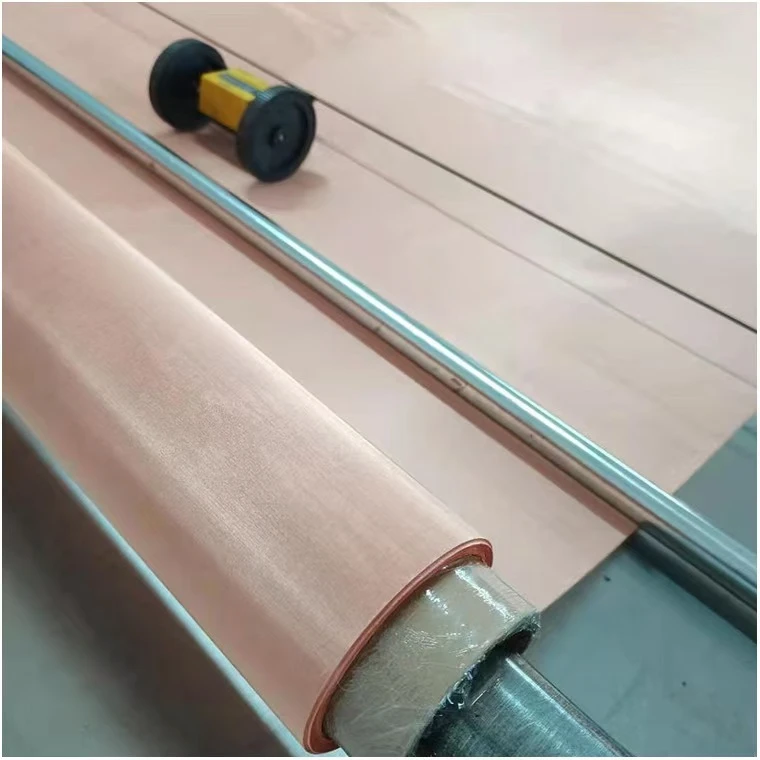

16g wire mesh

Understanding 16G Wire Mesh The Versatile and Essential Material

Wire mesh is a staple in various industries, offering a combination of strength, flexibility, and diverse applications. Among the different types of wire mesh, 16G wire mesh stands out for its unique characteristics and advantages. This article explores what 16G wire mesh is, its properties, applications, and the benefits of this versatile material.

What is 16G Wire Mesh?

The term 16G refers to a specific gauge of wire mesh, where 16G indicates the thickness of the wire used to create the mesh. In this instance, G stands for gauge, which is a standard measurement used to denote the diameter of the wire. The lower the gauge number, the thicker the wire, and thus 16 gauge is moderately thick while still being flexible enough to manipulate and install easily.

Wire mesh can be made from various materials, including stainless steel, carbon steel, galvanized steel, and aluminum. The choice of material impacts the mesh's resistance to corrosion, its weight, and its overall durability. 16G wire mesh can be found in both welded and woven forms, catering to specific needs in different applications.

Properties of 16G Wire Mesh

One of the key properties of 16G wire mesh is its balance between strength and weight. Its thickness provides significant structural integrity, making it suitable for various demanding applications. Additionally, the choice of material can enhance specific properties, such as corrosion resistance in stainless steel versions or increased weight-bearing capacity in carbon steel variants.

The mesh's open area—a factor that defines how much of the surface is open spaces compared to solid material—also plays a role in its applications. This open area allows for efficient airflow and drainage, making it ideal for projects requiring ventilation or filtration.

16g wire mesh

Moreover, the versatility of wire mesh allows for customization in terms of mesh size, opening dimensions, and roll lengths, enabling industries to adapt it for various purposes.

Applications of 16G Wire Mesh

16G wire mesh is used across many sectors due to its robustness and versatility. In construction, it serves as reinforcement in concrete applications, providing additional strength to structures. In the agricultural industry, it is commonly used for fencing, ensuring that livestock is contained while also keeping out predators.

In the realm of security, 16G wire mesh can be fabricated into gates and partitions, offering a strong barrier while allowing visibility. It is also used in crafts and DIY projects, where its flexibility allows for various creative design opportunities.

Furthermore, the automotive and manufacturing industries utilize 16G wire mesh for filters, grills, and protective screens. Its ability to withstand harsh conditions makes it a reliable choice in environments where strength and reliability are paramount.

Conclusion

In summary, 16G wire mesh is a vital material known for its durability, flexibility, and diverse applications. Its strength and adaptability make it suitable for a wide range of uses, from construction to agriculture and beyond. As industries continue to innovate, the importance of wire mesh, especially 16G varieties, in providing reliable solutions cannot be overstated. Whether you are working on a construction project, agricultural needs, or creative crafts, understanding the properties and applications of 16G wire mesh can greatly enhance your outcomes.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025