-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

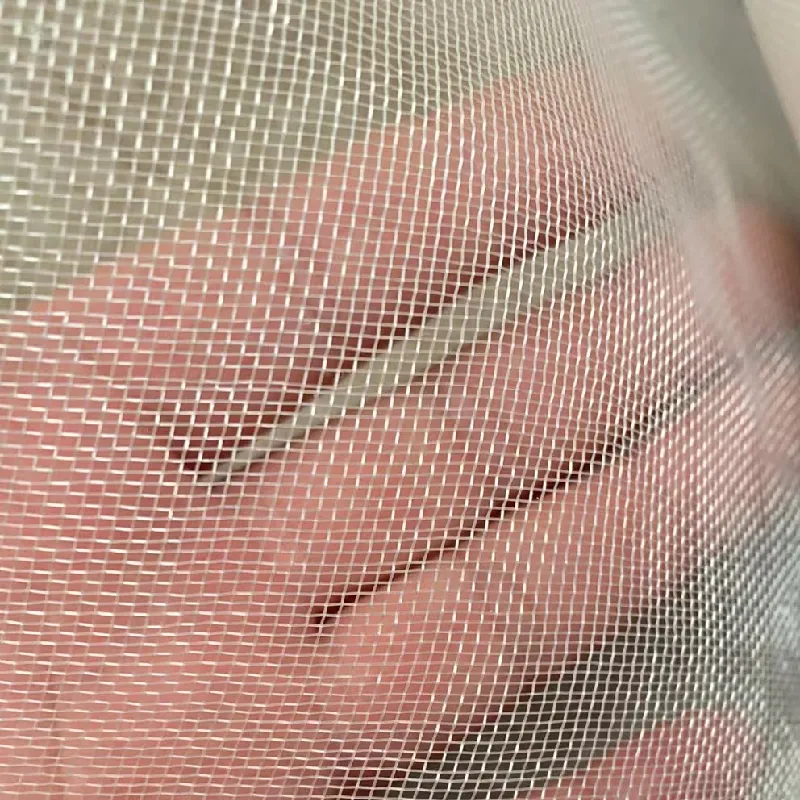

20 Micron Mesh Filter - High-Quality Filtration Solutions

Understanding 20 Micron Mesh Filters A Comprehensive Overview

Filtering is a crucial process across various industries, whether it’s in water treatment, chemical processing, or food and beverage production. One of the pivotal components in these filtering systems is the mesh filter, and among them, the 20-micron mesh filter stands out for its effectiveness in separating unwanted particles from liquids and gases.

What is a 20 Micron Mesh Filter?

A 20-micron mesh filter is designed to capture particles that are 20 micrometers or larger. To put this into context, a micrometer (micron) is one-millionth of a meter. This size of filtration is ideal for numerous applications, particularly where small particles can compromise system integrity or the quality of the end product.

Applications of 20 Micron Mesh Filters

1. Water Treatment In municipal water systems, 20-micron mesh filters are utilized to remove sediment, silt, and other contaminants from water. This pre-filtration step ensures that the water is cleaner before it undergoes further purification processes.

2. Chemical Processing The pharmaceutical and chemical industries rely heavily on 20-micron filters to maintain product quality. By removing impurities and particulate matter, these filters help in achieving consistent product specifications.

3. Food and Beverage In the food industry, hygiene and safety are paramount. 20-micron mesh filters play a vital role in ensuring that products such as oil, juices, and syrups are free of unwanted particles, thus maintaining flavor and safety standards.

4. Paint and Coatings In the production of paints and coatings, a 20-micron filter prevents dirt and other particulates from mixing into the product, which can affect its appearance and performance.

20 micron mesh filter

Benefits of Using 20 Micron Mesh Filters

1. Efficiency These filters provide an efficient means of separating unwanted particles, leading to enhanced product quality and system performance.

2. Cost-Effectiveness By utilizing a 20-micron mesh filter, industries can avoid costly downtime caused by equipment clogs and failures. Regular maintenance and replacement of filters can significantly extend the lifespan of machinery and equipment.

3. Versatility 20-micron mesh filters can be made from various materials, including nylon, polyester, and stainless steel, allowing for customized solutions according to specific industry needs.

Design and Maintenance Considerations

When choosing a 20-micron mesh filter, factors such as the flow rate, the type of fluid being filtered, and the contaminants present must be considered. Regular maintenance is crucial to ensure optimal performance. This includes cleaning or replacing filters as needed, depending on their application.

Conclusion

20-micron mesh filters are indispensable across numerous sectors, contributing to operational efficiency, product integrity, and safety. Their role in filtering out unwanted particles is vital, making them a popular choice for industries where quality is a priority. As technology advances, the design and application of these filters will continue to evolve, ensuring that they meet the increasing demands of various industries. Understanding the importance and functionality of these filters can lead to better decision-making and improved outcomes in filtration processes.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025