-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

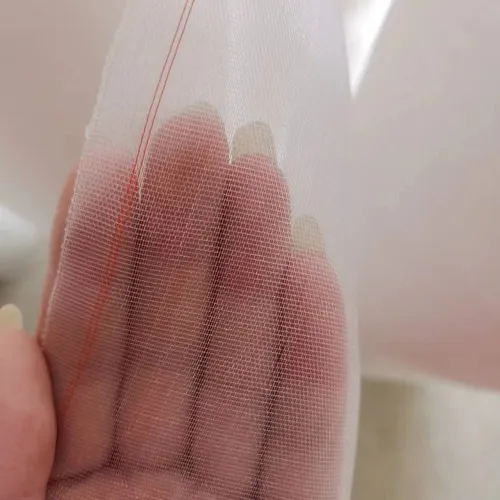

50 micron stainless steel filter

The Advantages of 50 Micron Stainless Steel Filters

In various industrial applications, filters play a vital role in ensuring the purity and quality of liquids and gases. Among the numerous types of filters available today, the 50-micron stainless steel filter stands out due to its unique combination of strength, durability, and efficient filtration capabilities. In this article, we will explore the advantages of using 50-micron stainless steel filters and their applications across different sectors.

Understanding Micron Filtration

The term micron refers to one-millionth of a meter. When we say a filter has a rating of 50 microns, we mean it can effectively filter out particles that are 50 microns in size or larger. This capability makes it suitable for various applications where the removal of sediments, dirt, and larger particulate matter is essential.

Durability and Strength

One of the primary advantages of stainless steel frames is their inherent strength and durability. Unlike filters made from other materials such as plastic or paper, stainless steel filters can withstand extreme pressures and temperatures without compromising their integrity. This resilience makes them ideal for industrial environments where harsh conditions might otherwise damage weaker filter materials.

Moreover, stainless steel is resistant to corrosion, which is crucial for applications involving corrosive fluids or gases. This characteristic ensures a long lifespan for the filter, reducing replacement frequency and overall maintenance costs.

Easy to Clean and Reuse

Another significant advantage of 50-micron stainless steel filters is their ease of maintenance. These filters can be cleaned efficiently, either through backwashing or manual cleaning. This reusability feature not only makes them environmentally friendly but also cost-effective, as industries can minimize waste and maintain a sustainable operation.

50 micron stainless steel filter

Cleaning stainless steel filters can often be done with simple solvents or detergents, making it a hassle-free process

. Many industrial facilities choose to invest in stainless steel filters for this very reason reducing downtime and ensuring continuous operation.Versatility in Applications

50-micron stainless steel filters are versatile and can be used across various sectors, including food and beverage production, pharmaceuticals, water treatment, and chemical processing.

- Food and Beverage Industry In the food industry, maintaining hygiene is paramount, and stainless steel filters can help ensure that food products are free from unwanted particulates. They play a crucial role in brewing processes, wine production, and juice filtration, assuring a high-quality final product.

- Pharmaceutical Industry The pharmaceutical sector requires stringent filtration standards. Stainless steel filters are often used in the production of sterile products to ensure that no contaminants compromise the efficacy of medications and vaccines.

- Water Treatment For water treatment facilities, 50-micron stainless steel filters can effectively remove silt, sand, and other large particles from water. This preliminary filtration is essential before further purification steps, allowing facilities to deliver clean, safe water to communities.

- Chemical Processing In chemical processing, maintaining purity while preventing the contamination of chemicals is crucial. Stainless steel filters provide the reliability and strength needed to filter various chemicals without the risk of degradation.

Conclusion

In summary, 50-micron stainless steel filters offer a plethora of advantages that make them invaluable across multiple industries. Their durability, ease of cleaning, and versatility underscore their role in maintaining high filtration standards essential for product quality and safety. As industries continue to seek more efficient and sustainable solutions, stainless steel filters will undoubtedly remain a popular choice among filtration options. Investing in these filters not only ensures compliance with industry standards but also promotes operational efficiency and environmental responsibility.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025