-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

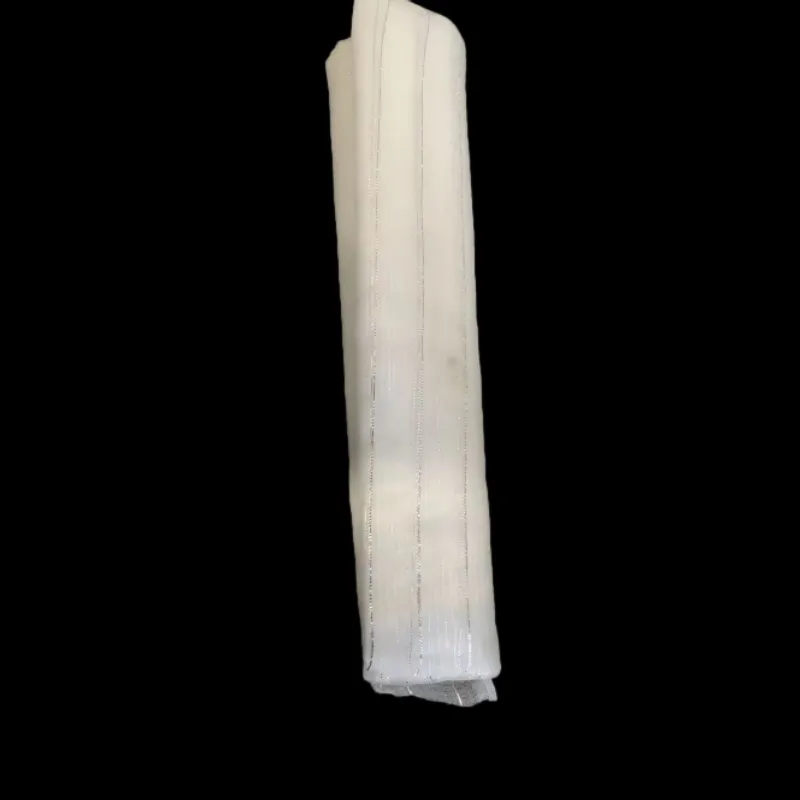

5 micron mesh filter

Understanding 5% Micron Mesh Filters Applications and Benefits

In the world of filtration, the effectiveness of a system often hinges on the type of filter used. Among the various filtration options, 5% micron mesh filters have emerged as a crucial tool in numerous industries, driving efficiency and enhancing product quality. These filters are renowned for their ability to sieve out microscopic particles, making them indispensable in applications ranging from pharmaceuticals to food production. This article delves into the significance, advantages, and applications of 5% micron mesh filters.

What is a 5% Micron Mesh Filter?

A 5% micron mesh filter is designed to trap particles that are 5 microns in size or larger. The designation 5% refers to the percentage of the aperture openings in the mesh that allow fluid to pass while capturing unwanted material. These filters enable efficient separation of solid contaminants from liquids or gases, ensuring that the downstream processes or products maintain stringent quality standards.

Importance of Micron Rating

Micron ratings are pivotal in determining the filter’s suitability for specific applications. A micron is one-millionth of a meter, and a 5-micron filter is capable of blocking particulate matter, such as dust, microbes, and other pollutants that can be detrimental to production processes or end products. For example, in the food and beverage industry, using a 5% micron mesh filter can help eliminate potential contaminants, ensuring consumer safety and compliance with health regulations. In the pharmaceutical industry, these filters are essential to maintain the purity of medicinal products.

Key Benefits of 5% Micron Mesh Filters

1. High Filtration Efficiency One of the standout features of 5% micron mesh filters is their high filtration efficiency. They effectively remove small particles without significantly impeding the flow of liquids or gases. This balance of performance and flow rate is crucial for many applications where maintaining production speed is essential.

2. Cost-Effectiveness While there may be initial costs associated with the installation of high-quality mesh filters, their ability to reduce wear and tear on equipment can lead to significant long-term savings. By preventing contaminants from entering machinery, companies can avoid costly repairs and extend the lifespan of their equipment.

3. Versatility 5% micron mesh filters can be utilized across a variety of industries, including chemical processing, oil and gas, water treatment, and agriculture. This versatility makes them a valuable asset for companies looking to standardize their filtration systems.

5 micron mesh filter

4. Improved Product Quality By removing impurities from liquids and gases, these filters enhance the overall quality of the final product. In industries such as cosmetics and pharmaceuticals, the purity of ingredients is paramount, and a 5% micron mesh filter can help ensure that end products meet high-quality standards.

5. Ease of Maintenance Many modern 5% micron mesh filters are designed for easy maintenance and cleaning. This ease of access is vital for ensuring that the filters can be routinely serviced without prolonged downtimes, thus keeping production processes running smoothly.

Applications of 5% Micron Mesh Filters

- Water Treatment In municipal water supply systems, 5% micron mesh filters play a crucial role in removing sediments and larger particles, thereby improving water quality and safety.

- Food Industry From brewing to bottling processes, these filters help ensure that food products are free from unwanted solids, enhancing both taste and safety.

- Pharmaceutical Manufacturing In drug production, maintaining sterility and purity is critical. 5% micron mesh filters assist in ensuring that any particulates that could compromise product integrity are removed.

- Chemical Processing These filters are used to clarify solvents and remove contaminants during the production of chemicals, ensuring a higher purity end product.

Conclusion

The importance of 5% micron mesh filters cannot be overstated. Their ability to effectively separate contaminants while promoting product quality makes them an invaluable tool across various sectors. As industries continue to evolve and demand higher standards, the reliance on advanced filtration solutions like 5% micron mesh filters is set to grow. By investing in these filters, companies not only enhance their operational efficiency but also ensure the safety and satisfaction of their consumers.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025