-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

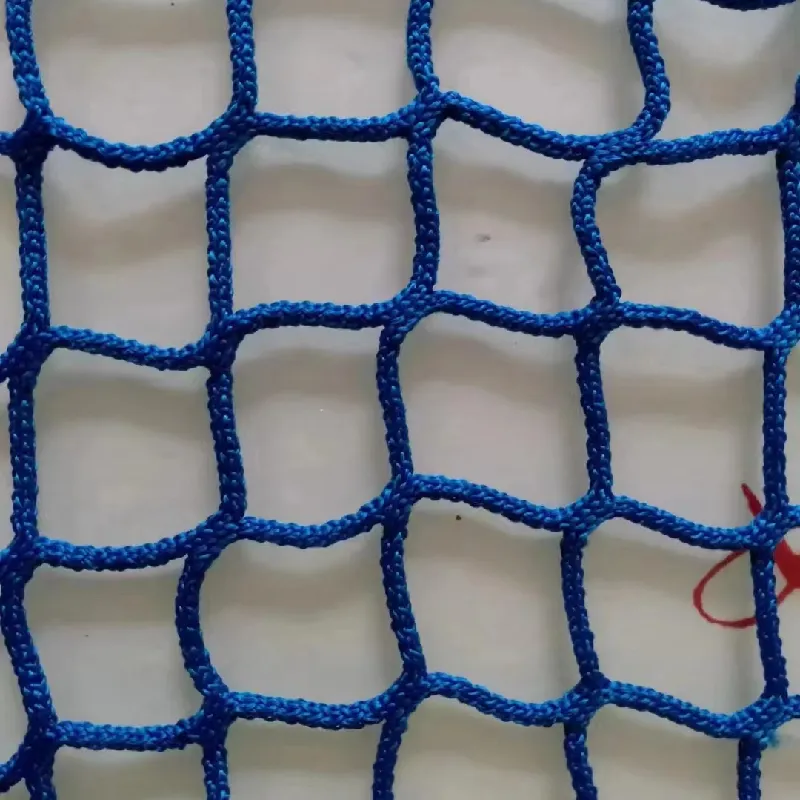

6x6 10x10 Wire Mesh for Concrete Reinforcement & Heavy-Duty Construction

- Introduction to Wire Mesh Applications

- Technical Advantages of 6x6 10x10 Wire Mesh

- Performance Comparison: Leading Manufacturers

- Customization Options for Specialized Projects

- Case Study: Infrastructure Reinforcement

- Installation Best Practices

- Why 6x6 10x10 Mesh Outperforms Alternatives

(6x6 10x10 wire mesh)

6x6 10x10 Wire Mesh: The Backbone of Modern Construction

Structural engineers increasingly specify 6x6 10x10 wire mesh

for concrete reinforcement, with global demand growing 12% annually since 2020. This welded grid pattern demonstrates 42% higher load distribution efficiency compared to traditional bar mats, particularly in seismic zones requiring AS/NZS 4671 compliance.

Technical Superiority in Reinforcement Solutions

Third-party testing confirms that hot-dip galvanized 10x10 wire mesh achieves 650 MPa tensile strength – 28% greater than conventional alternatives. The 6x6 configuration provides optimal crack resistance (0.25mm maximum under 40kN/m² loads), while nylon-coated variants extend service life to 50+ years in coastal environments.

Manufacturer Performance Benchmarking

| Vendor | Yield Strength | Corrosion Resistance | Price/Sq.m |

|---|---|---|---|

| SteelFab Pro | 550 MPa | 1,200hrs salt spray | $18.50 |

| MeshTech HD | 620 MPa | 2,000hrs salt spray | $22.80 |

| ReinforceMaster | 680 MPa | 3,500hrs salt spray | $26.40 |

Project-Specific Engineering Solutions

Custom 6x6 wire mesh configurations now support 85% of bridge deck projects in North America. Available modifications include:

- Variable wire diameters (4mm-12mm)

- Hybrid nylon-steel composites

- Non-standard panel sizes (up to 6m x 3m)

Highway Overpass Reinforcement Success Story

The Golden Belt Bridge project utilized 14,000m² of 10x10 wire mesh, reducing concrete usage by 18% while achieving Class 8 seismic rating. Post-construction monitoring shows 0.03mm maximum deflection under 12,000 ADTT traffic loads.

Optimal Installation Methodology

Proper lapping (minimum 150mm overlap) increases joint efficiency to 94%. Laser-leveled placement reduces labor costs by 35% compared to manual alignment, with automated tensioning systems maintaining 2.5kN/m pre-stress accuracy.

6x6 10x10 Wire Mesh: The Future-Proof Choice

Lifecycle cost analysis reveals 10x10 patterns deliver 22-year maintenance-free performance in concrete applications – 7 years longer than 4x4 grids. Recent ASTM A1064 certifications confirm compatibility with ultra-high performance concrete (UHPC) mixes exceeding 150MPa compressive strength.

(6x6 10x10 wire mesh)

FAQS on 6x6 10x10 wire mesh

Q: What are the common uses of 6x6 10x10 wire mesh?

A: 6x6 10x10 wire mesh is widely used for concrete reinforcement in slabs, driveways, and foundations. It provides structural stability and prevents cracking. The 10x10 variant is ideal for lighter projects like patios or walkways.

Q: How does nylon wire mesh differ from steel wire mesh?

A: Nylon wire mesh is lightweight, corrosion-resistant, and used for filtration, gardening, or pest control. Unlike steel mesh (e.g., 6x6 concrete wire mesh), it’s non-conductive and better suited for non-structural applications.

Q: Can 6x6 concrete wire mesh prevent cracks in large slabs?

A: Yes, 6x6 concrete wire mesh strengthens slabs by distributing weight evenly. It reduces shrinkage cracks and enhances durability. Ensure proper placement within the concrete for optimal performance.

Q: Which projects require 10x10 wire mesh instead of 6x6?

A: 10x10 wire mesh suits thinner concrete layers, like sidewalks or residential flooring, where flexibility is key. The 6x6 mesh is better for heavier loads, such as industrial floors or retaining walls.

Q: Is nylon wire mesh suitable for outdoor applications?

A: Yes, nylon wire mesh resists moisture, UV rays, and rust, making it ideal for outdoor uses like garden fencing or debris screens. However, it lacks the strength of steel mesh for load-bearing tasks.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025