-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

airbag container

The Importance of Airbag Containers in Automotive Safety

As road travel remains an essential mode of transportation worldwide, enhancing vehicular safety has become a priority in the automotive industry. Among the myriad of safety features designed to protect occupants in the event of a collision, airbags stand out as one of the most effective preventative measures. However, the effectiveness of airbags relies not only on their design and deployment mechanism but also significantly on the airbag containers that house these vital safety devices.

Airbag containers, commonly referred to as airbag modules, are specifically engineered components designed to house the airbag itself, inflators, and electronic control units. These containers are typically made from durable materials such as high-strength plastics or metal alloys, which are capable of withstanding harsh conditions while providing adequate protection to the airbag system. Their primary role is to protect the airbag during the vehicle's lifecycle, ensuring it remains in optimal condition until deployment is necessary.

One of the essential functions of airbag containers is to provide a secure and stable environment for the airbag when it is not deployed. The airbag must be stored in a compressed state to fit seamlessly into the vehicle's interior design. The container's structural integrity is critical; it must prevent any wear or damage that could impair the airbag's deployment mechanism. Engineers meticulously design these containers to withstand various environmental factors such as extreme temperatures, moisture, and vibrations typically experienced in automotive applications.

airbag container

In addition to protection, airbag containers play a significant role in the deployment mechanism. When a collision occurs, sensors detect the impact and trigger the inflator to fill the airbag with gas almost instantaneously. This rapid deployment, often within milliseconds, is crucial as every second counts in ensuring the safety of the occupants. The container needs to be designed to release the airbag smoothly and effectively without any obstructions. Poorly designed containers can lead to issues such as delayed deployment or misalignment, significantly increasing the risk of injury.

Moreover, safety regulations and standards heavily impact the engineering and manufacturing of airbag containers. Regulatory bodies impose strict guidelines that manufacturers must adhere to, ensuring that these containers satisfy stringent safety and performance criteria. Continuous advancements in technology and materials science have led to the development of lighter yet robust designs, contributing to overall vehicle efficiency while maintaining safety standards.

Furthermore, the recent push for sustainability in the automotive sector has ushered in innovations in the production of airbag containers. Many manufacturers are exploring eco-friendly materials and processes to reduce their environmental impact. This shift not only aligns with global sustainability goals but also reflects the growing consumer demand for environmentally responsible products.

In conclusion, airbag containers are vital components in modern automotive safety systems. They protect airbag systems throughout the vehicle's lifespan and ensure rapid and effective deployment during a collision. As safety regulations evolve and consumers prioritize sustainable practices, ongoing innovation in airbag container design and manufacturing will play an integral role in advancing vehicular safety. Understanding the importance of these components is essential for appreciating the complexities of automotive safety engineering and the life-saving technologies that protect millions of drivers and passengers on the road today.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

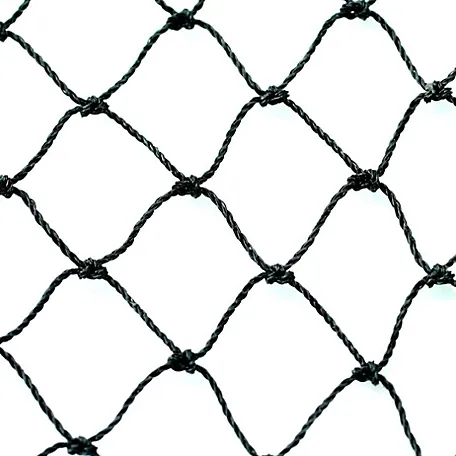

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025