Anti Bird Netting – UV-Stable, Durable, Humane Protection

Smarter Bird Control: What’s Working in 2025

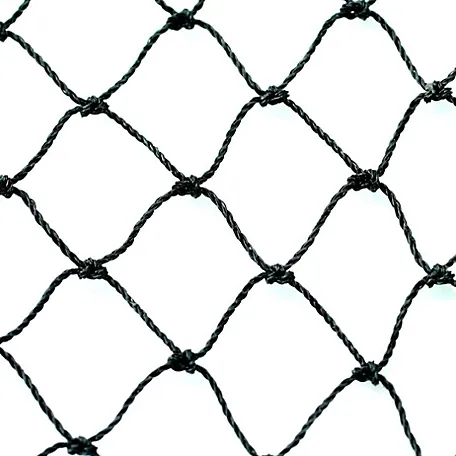

If you’ve watched grapes disappear overnight—or picked gull feathers out of HVAC grilles—you know the quiet power of Anti Bird Netting. I’ve toured enough orchards, stadium roofs, and warehouse canopies to say this with a straight face: simple nets still beat gadgets nine times out of ten. The latest generation, especially polyethylene with a strong UV package, lasts longer than the folklore suggests, and yes, looks cleaner on camera drones too.

What’s new: materials, colors, and real-world durability

The Black White Knotted Anti Bird Netting Polyethylene Anti Brid Netting (Origin: China) rides a trend we’re seeing everywhere: UV-stabilized PE (often HDPE) with denser carbon-black or light-stabilizer masterbatches, tighter QA on twine drawing, and more sizes out of the box. Knotted for structure, knotless for low visual impact—choose based on wind load and aesthetics. Many customers say black “disappears” against foliage, while white is easier to see during installation on high roofs. Both options are popular; it depends on context, honestly.

Key specifications (practical, not just lab talk)

| Parameter | Typical Value (≈ / real-world may vary) |

|---|---|

| Material | UV-stabilized polyethylene (HDPE/PE) |

| Construction | Knotted or knotless; square mesh |

| Mesh size | ≈ 15–50 mm (finch to pigeon control) |

| Twine diameter | ≈ 0.6–1.2 mm |

| Weight | ≈ 12–50 g/m² |

| Tensile / mesh break | ≥ 75–120 N (ISO 1806 guidance) |

| UV exposure endurance | ≥ 3,000–5,000 h xenon-arc (ISO 4892-2) |

| Service life | ≈ 5–8 years outdoors (climate dependent) |

| Color | Black / White |

| Widths / lengths | Up to ≈ 25 m wide; 50–200 m rolls |

| Compliance | RoHS / REACH-friendly; ISO 9001 factory |

How it’s made and tested (short version)

Materials: PE pellets + UV masterbatch → Extrusion & drawing → Twine stabilization → Knitting/knotted formation → Heat setting → Edge reinforcement → QC.

Testing & standards: mesh break per ISO 1806; strip tensile (ASTM D5035) where applicable; UV aging (ISO 4892-2); dimensional tolerance (±3% mesh); inspection for knots, joins, and color uniformity. Service life varies—coastal UV and ammonia from bird droppings do add stress, to be honest.

Where it’s used

- Vineyards, berries, orchards (cherries, olives) — reduce peck loss.

- Warehouses, hangars, stadium roofing — discreet façade protection.

- Aquaculture and marinas — keep birds off feed and line arrays.

- Solar farms and façades — protect cabling and vent gaps.

Vendor snapshot (what buyers usually compare)

| Vendor | Material & UV | Mesh options | Customization | Lead time | Certs |

|---|---|---|---|---|---|

| YJ Wire Mesh (China) | HDPE + UV, black/white | ≈ 15–50 mm, knotted/knotless | Cut-to-size, edging, grommets | ≈ 10–20 days | ISO 9001; test reports |

| Regional Distributor | PE/PP mix, varying UV | Limited sizes | Basic | Stock-dependent | Supplier-declared |

| DIY Retail Brand | Lightweight PE | Small meshes only | None | Immediate (store) | Basic compliance |

Field notes and mini case studies

A New Zealand vineyard switched to Anti Bird Netting with 20 mm mesh and reported ≈ 80% less fruit loss in the first harvest cycle. In Spain, an olive co-op preferred white Anti Bird Netting for visibility during rapid seasonal installs—fewer snagged branches, faster takedown. A logistics client used black Anti Bird Netting over rafters; droppings decreased by ≈ 90%, which quietly improved forklift traction (a real safety win).

Customization tips

- Choose mesh by target species; smaller birds need ≈ 15–20 mm.

- Edge with UV rope and order corner loops for high-wind sites.

- Consider white nets for rooftop installs—easier maintenance.

- Ask for ISO 1806 and UV (ISO 4892-2) test data; it matters.

Standards & references:

- ISO 1806:2018 — Fishing nets — Determination of mesh breaking force of netting. https://www.iso.org/standard/65299.html

- ISO 4892-2:2013 — Plastics — Methods of exposure to laboratory light sources — Part 2. https://www.iso.org/standard/45850.html

- ASTM D5035 — Breaking Force and Elongation of Textile Fabrics (Strip Method). https://www.astm.org/d5035

- REACH Regulation (EC) No 1907/2006 — ECHA. https://echa.europa.eu/regulations/reach

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025