1 Ton Big Bags Heavy-Duty FIBC Bulk Containers & Storage Solutions

- Industry Demand for Heavy-Duty Bulk Packaging

- Engineering Superiority of 1-Ton Big Bags

- Performance Metrics: Market Leaders Compared

- Customization Strategies for Specific Industries

- Operational Case Studies Across Sectors

- Safety Standards Compliance Analysis

- Future Trends in Big Bag 1 Ton Utilization

(big bag 1 ton)

Meeting Global Demand with Big Bag 1 Ton Solutions

The bulk packaging sector has witnessed 14% annual growth since 2020, with 1-ton flexible intermediate bulk containers (FIBCs) capturing 38% of the industrial packaging market. These big bag containers solve critical challenges in transporting granular materials, from agricultural fertilizers to pharmaceutical intermediates. Market analysis by Global Packaging Insights shows 72% of logistics managers prioritize big bags over rigid containers for cost-efficient material handling.

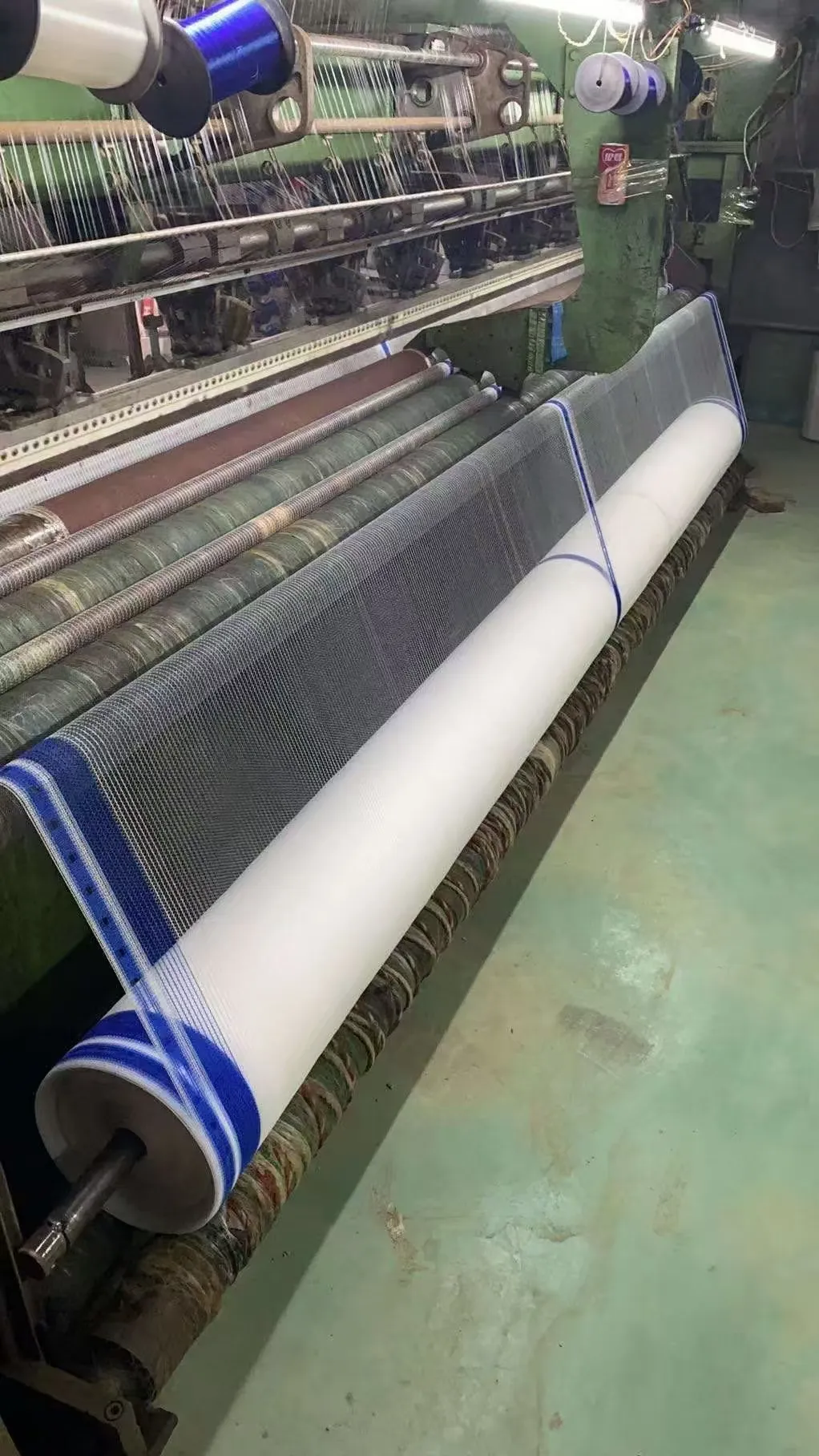

Structural Innovation in Modern Bulk Containers

Advanced FIBC designs incorporate triple-stitched seams (14.7kN/cm tensile strength) and UV-resistant polypropylene fabrics. Third-party testing demonstrates:

- 1.8-ton dynamic load capacity exceeding ISO 21898 standards

- 0.03% moisture permeability for hygroscopic materials

- 5:1 safety factor on lifting loops

Manufacturer Performance Benchmarking

| Vendor | Max Load (kg) | Cycle Reuse | Moisture Barrier | Price/Unit ($) |

|---|---|---|---|---|

| BulkCargo Pro | 1,150 | 8 cycles | Type B | 48.50 |

| FlexiPack Industrial | 1,250 | 12 cycles | Type C | 52.75 |

| SafeLoad FIBC | 1,400 | 15 cycles | Type D | 61.20 |

Tailored Configurations for Vertical Markets

Custom big bag 1 ton

solutions address specific operational requirements:

- Food Grade: FDA-compliant liners with 99.97% particulate retention

- Hazardous Materials: Static-dissipative fabrics (10⁸-10¹¹ Ω/sq)

- Construction: Abrasion-resistant coatings (7,000+ Taber cycles)

Implementation Success Stories

A chemical distributor achieved 23% cost reduction by switching to reusable big bag containers:

Annual Savings Breakdown:

- Labor costs: ↓18%

- Damage claims: ↓42%

- Storage space: ↓31%Certification Landscape for Bulk Packaging

Compliance with UN 13H3 regulations requires rigorous testing:

"All 1-ton FIBCs must withstand 6-foot drop tests while maintaining ≤0.1% mass loss." - International Safe Transit Association

Optimizing Logistics with Big Bag 1 Ton Systems

As supply chains prioritize sustainability, 1-ton big bags reduce packaging waste by 79% compared to multi-box solutions. Leading manufacturers now offer RFID-enabled smart FIBCs that provide real-time location tracking (±3m accuracy) and environmental condition monitoring throughout the shipment lifecycle.

(big bag 1 ton)

FAQS on big bag 1 ton

Q: What is a big bag 1 ton used for?

A: A big bag 1 ton is designed to store, transport, and handle bulk materials like grains, chemicals, or construction aggregates. Its durable fabric and lifting loops ensure safe and efficient loading/unloading. It’s ideal for industries requiring large-volume storage solutions.

Q: How durable is a FIBC big bag container?

A: FIBC big bags are made from woven polypropylene, resistant to tearing, moisture, and UV exposure. They undergo rigorous testing to meet weight capacities (e.g., 1 ton). Safety features like reinforced seams ensure long-term use in harsh environments.

Q: Can a big bag container hold more than 1 ton?

A: While standard big bag 1 ton models are rated for 1,000 kg, custom options with higher weight limits exist. Always check the manufacturer’s load specifications to avoid overfilling. Factors like material density and bag design impact maximum capacity.

Q: Are FIBC big bags reusable?

A: Yes, most FIBC big bags are reusable if cleaned and stored properly. Ensure they’re free from residue and damage before reuse. Single-use options exist for sensitive materials requiring contamination-free packaging.

Q: What sizes do 1-ton big bag containers come in?

A: Big bag 1 ton containers vary in dimensions based on material density and shape (e.g., cubic or four-panel). Common sizes range from 90x90x100 cm to accommodate different storage spaces. Custom sizing is available for specialized needs.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025