-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Producers of Chicken Wire for Agricultural and Construction Use

Understanding Chicken Wire Manufacturers A Comprehensive Overview

Chicken wire, also known as poultry netting or hexagonal wire mesh, has become an essential material for many agricultural, gardening, and construction applications. The versatility and efficiency of chicken wire make it a preferred choice among farmers, gardeners, and DIY enthusiasts. This article will delve into the world of chicken wire manufacturers, exploring their products, production processes, and the various applications of chicken wire.

The Role of Chicken Wire Manufacturers

Chicken wire manufacturers specialize in the production of mesh fencing typically made from galvanized steel, although variations such as plastic-coated wire are also available. The primary purpose of chicken wire is to enclose poultry, preventing them from wandering off while allowing for ventilation and light. However, the use of chicken wire extends beyond keeping chickens. It is widely used for gardening purposes—protecting plants from predators, creating compost bins, and defining garden beds.

Manufacturers of chicken wire aim to meet diverse customer requirements. This might involve producing different mesh sizes, which are tailored to fit specific needs. Smaller mesh sizes are ideal for keeping out smaller animals, while larger openings may suffice for protecting larger plants or crops. Additionally, various wire gauges (thicknesses) are available, offering different levels of durability and strength.

The Production Process

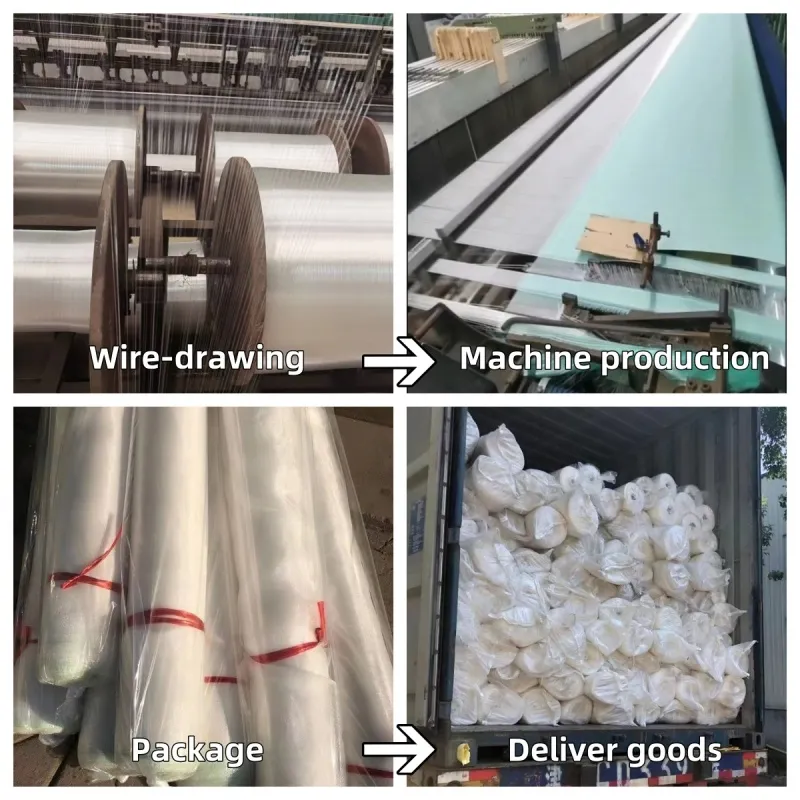

The production of chicken wire involves several steps. First, raw materials—typically steel wire—are sourced. This wire is then drawn down to the desired gauge. Once the wire has been prepped, it's shaped into hexagonal patterns. This is typically done using machines that can weave the wire accurately and consistently.

After shaping, the wire mesh is often galvanized to enhance its resistance to corrosion. Galvanization involves coating the wire with a layer of zinc to protect it from environmental factors such as moisture and rust. Manufacturers may also offer options with plastic coatings for additional protection and aesthetic purposes.

chicken wire manufacturers

Once the chicken wire is produced, it is rolled into manageable sizes for shipping. Depending on the manufacturer, customers can order chicken wire in various widths and lengths, accommodating both small-scale and large-scale projects.

Applications of Chicken Wire

As previously mentioned, chicken wire has a multitude of applications beyond poultry farming. In gardening, it serves as an effective deterrent against rabbits, deer, and other pests. Home gardeners often use chicken wire to create barriers around their plants or as trellising for climbing vegetables like beans and peas.

In landscaping, chicken wire can be used to stabilize soil and create supports for various types of plant life. It is particularly useful in creating fencing for herb gardens or flower beds, providing both protection and aesthetic appeal.

Moreover, chicken wire is popular in crafting and home decor. Artisans often utilize the mesh material in projects ranging from decorative wall art to unique light fixtures. Its flexibility and structure enable a range of creative uses, making chicken wire a beloved material among DIY enthusiasts.

Conclusion

In conclusion, chicken wire manufacturers play a crucial role in supplying a versatile product that meets the needs of farmers, gardeners, and crafters alike. The production process, from wire drawing to galvanization, ensures that the final product is durable and effective for various applications. As the demand for sustainable and practical materials continues to grow, chicken wire remains a staple in many households and businesses. Whether you're enclosing a chicken coop or decorating your home, understanding chicken wire and its producers can help you make informed decisions for your next project.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025