-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

concrete reinforcement merchant steel metal fabric mesh

Concrete Reinforcement Exploring the Significance of Merchant Steel Metal Fabric Mesh

Concrete is one of the most widely used construction materials in the world, renowned for its durability and strength. However, despite its robust properties, concrete alone can be susceptible to cracking and tensile stresses. To enhance its structural integrity, engineers and builders often incorporate various reinforcement methods, one of which includes the use of merchant steel metal fabric mesh. This article delves into the significance of this crucial component in concrete reinforcement, discussing its properties, applications, and the advantages it offers.

Understanding Metal Fabric Mesh

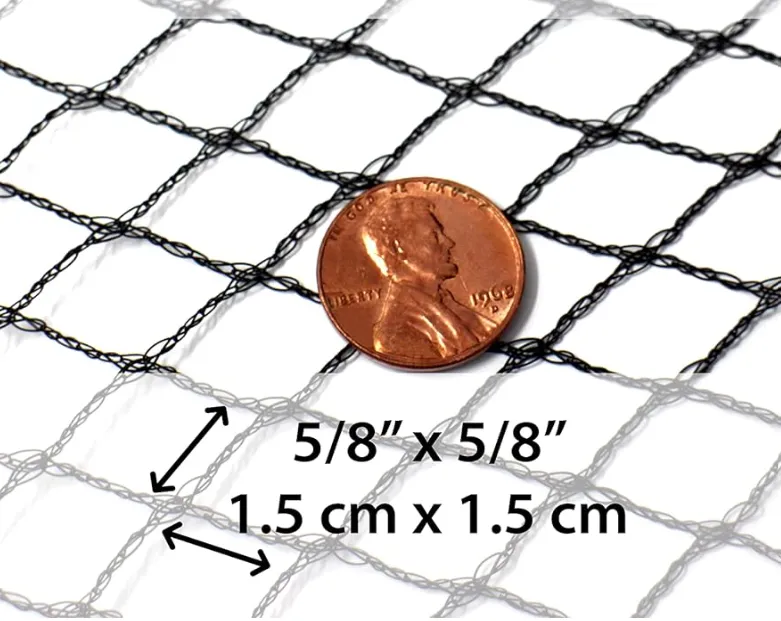

Metal fabric mesh, often referred to as wire mesh or reinforcement mesh, consists of a grid of interconnected steel wires. It is manufactured in various gauges and mesh sizes, enabling customization to meet specific project requirements. Merchant steel, characterized by its quality and consistency, provides the ideal material for producing this mesh. The fabrication process involves welding or weaving steel wires, resulting in a sturdy and reliable product.

The Role of Metal Fabric Mesh in Concrete Reinforcement

The primary function of metal fabric mesh in concrete reinforcement is to improve the tensile strength of the concrete. Concrete is strong in compression but weak in tension, making it prone to cracking under stress. By integrating steel mesh into the concrete matrix, tensile forces can be distributed evenly, preventing localized stress concentrations that could lead to structural failure. This reinforcement method is particularly effective in slabs, pavements, and walls, where tension forces are frequently encountered.

Applications of Merchant Steel Metal Fabric Mesh

Merchant steel metal fabric mesh finds its applications across various sectors within the construction industry. Some common uses include

1. Slabs and Pavements Metal mesh is often laid beneath concrete slabs and in pavement construction to enhance load distribution and reduce the risk of cracking. This is especially vital in high-traffic areas where the likelihood of stress fractures is higher.

concrete reinforcement merchant steel metal fabric mesh

3. Precast Elements Precast concrete elements, such as panels and beams, often incorporate metal fabric mesh to ensure they meet the necessary strength and load-bearing requirements before being installed on-site.

4. Reinforced Structures In structures such as bridges and parking garages, where significant tensile forces are present, metal fabric mesh provides the additional support needed for enhanced durability and safety.

Benefits of Using Merchant Steel Metal Fabric Mesh

The utilization of merchant steel metal fabric mesh in concrete reinforcement offers several advantages

1. Enhanced Strength and Stability By integrating steel mesh within concrete, structures gain added tensile strength, leading to improved overall stability.

2. Crack Prevention The mesh distributes stress evenly within the concrete, effectively minimizing the potential for cracks and prolonging the lifespan of the structure.

3. Cost-Effectiveness While the initial investment in metal fabric mesh may seem significant, the long-term benefits, including reduced repair costs due to fewer cracks and structural failures, make it a cost-effective solution.

4. Versatility With various sizes and configurations available, merchant steel metal fabric mesh can be tailored to suit a wide range of applications, making it a versatile choice for contractors and engineers.

Conclusion

In conclusion, merchant steel metal fabric mesh plays an essential role in the reinforcement of concrete, addressing its inherent weaknesses and significantly enhancing its performance. From slabs and pavements to foundation walls and precast components, the applications of metal mesh are diverse and impactful. As the construction industry continues to evolve, the importance of innovative reinforcement solutions like merchant steel metal fabric mesh cannot be overstated. By prioritizing the use of high-quality materials and effective reinforcement methods, engineers and builders can create safer, more resilient structures that stand the test of time. Whether for small residential projects or large-scale commercial developments, the versatility and reliability of metal fabric mesh make it a cornerstone in modern concrete construction.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025