-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

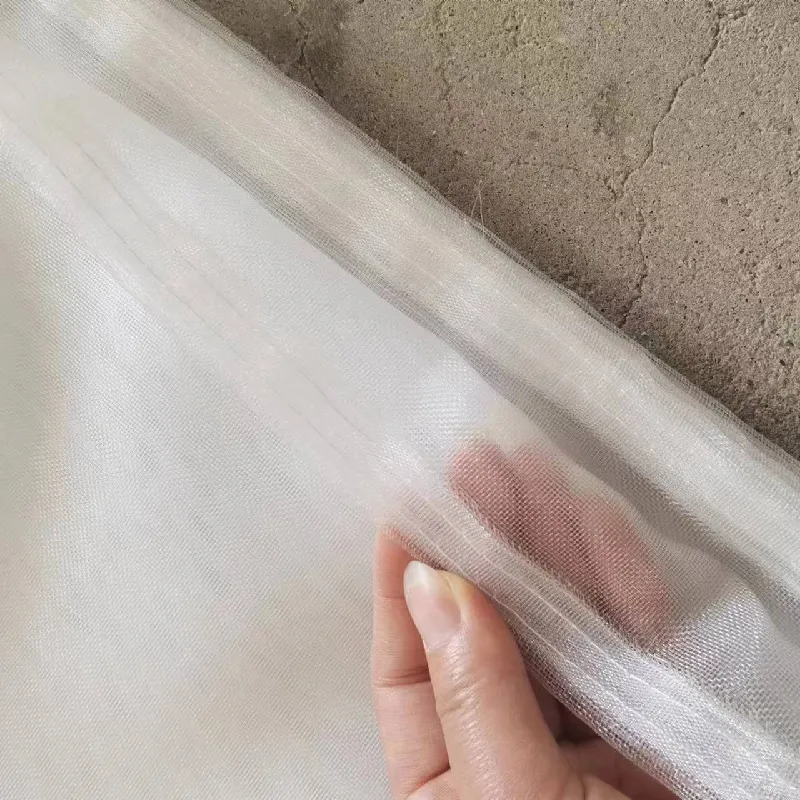

Steel Fabric Mesh for Concrete Reinforcement in Merchant Applications

The Importance of Concrete Reinforcement A Focus on Metal Fabric Mesh

Concrete is one of the most widely used building materials in the world, known for its durability and strength. However, on its own, concrete can be quite brittle and prone to cracking under tension. To enhance its structural integrity and longevity, reinforcing materials are often incorporated. Among the various methods available, metal fabric mesh stands out as a vital component in concrete reinforcement.

Understanding Metal Fabric Mesh

Metal fabric mesh, often referred to as steel mesh or welded wire mesh, is a network of interconnected steel wires or bars that provide tensile strength to concrete structures. This mesh is produced in various sizes and configurations, allowing for versatility in application based on the specific needs of a construction project. The mesh is typically made from high-strength steel wires that are welded together to form a grid-like structure, capable of withstanding significant stress.

How Metal Fabric Mesh Reinforces Concrete

Concrete has excellent compressive strength, making it ideal for bearing heavy loads. However, when subjected to tensile forces, it can crack and fail. This is where metal fabric mesh comes into play. By embedding the mesh within the concrete, the steel wires provide additional tensile strength, effectively distributing loads and minimizing the risk of cracking. This improves the overall performance of the concrete, especially in applications involving slabs, walls, and pavements.

Benefits of Using Metal Fabric Mesh

1. Improved Structural Integrity Metal fabric mesh significantly enhances the structural integrity of concrete elements, reducing the likelihood of tensile-related failures. It ensures that the distribution of forces is more uniform, allowing concrete structures to perform better under varied loads.

2. Crack Resistance With the added tensile strength, the mesh helps in controlling and minimizing cracking. This is particularly important in environments subjected to temperature fluctuations or where heavy traffic is anticipated.

concrete reinforcement merchant steel metal fabric mesh

3. Cost-Effectiveness Using metal fabric mesh can lead to cost savings in the long run. By reducing the need for excessive thickness in concrete elements and minimizing maintenance costs associated with repairs from cracking, builders can deliver more economically viable projects.

4. Ease of Use Metal fabric mesh is relatively easy to handle and install. It can be cut and shaped to fit various applications, making it a convenient choice for construction professionals. Furthermore, its lightweight nature streamlines the transportation and handling process on-site.

5. Versatility The adaptability of metal fabric mesh makes it suitable for a range of applications, from residential to commercial construction. It can be used in floors, walls, roofs, and even precast elements, proving effective in numerous structural scenarios.

Environmental Considerations

In today’s construction industry, sustainability is gaining importance. Steel, being a recyclable material, aligns well with eco-friendly practices. The use of metal fabric mesh contributes to reducing the carbon footprint of buildings by minimizing the quantity of concrete needed and extending the lifespan of concrete structures through enhanced durability.

Future Trends

As construction technology continues to advance, the methods of reinforcing concrete are evolving. Innovations in the production and application of metal fabric mesh are expected, including the integration of fiber-reinforced polymers and other composites that aim to further enhance the performance of concrete. Moreover, the increased focus on sustainable building practices is likely to drive research into more environmentally friendly reinforcing materials that balance strength with ecological impact.

Conclusion

Concrete reinforcement through the use of metal fabric mesh is an essential aspect of modern construction. By providing the necessary tensile strength, this material not only enhances the durability and performance of concrete structures but also contributes to cost savings and sustainability efforts in the industry. As technology continues to advance, the role of metal fabric mesh is likely to expand, driving innovations that will allow for even more resilient and efficient concrete applications in the future. As builders and engineers strive for excellence in their projects, the integration of effective reinforcement techniques will remain a critical focus, with metal fabric mesh at the forefront of these efforts.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025